Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

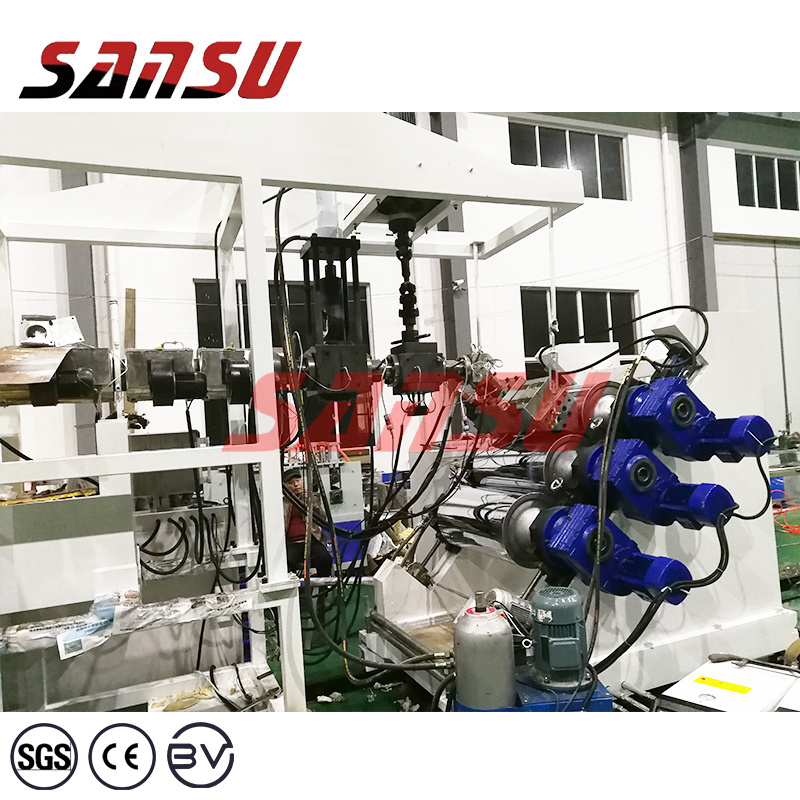

Sansu

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12*2*2M

-

Power (kW):

-

110

-

Weight:

-

6T

-

Warranty:

-

15 months, 15months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

plastic sheet extrusion machine

-

Raw material:

-

PET bottle

-

Inverter:

-

ABB

-

Capacity:

-

300-400kg/h

-

Temperature controller:

-

RKC

-

Contactor:

-

Schnerder

-

Power(W):

-

5.5kw

-

Automatic Grade:

-

automation

-

Output (kg/h):

-

180 - 600

-

Certification:

-

CE ISO

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

16:1

-

Screw diameter (mm):

-

120 mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sansu

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

12*2*2M

-

Power (kW):

-

110

-

Weight:

-

6T

-

Warranty:

-

15 months, 15months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

plastic sheet extrusion machine

-

Raw material:

-

PET bottle

-

Inverter:

-

ABB

-

Capacity:

-

300-400kg/h

-

Temperature controller:

-

RKC

-

Contactor:

-

Schnerder

-

Power(W):

-

5.5kw

-

Automatic Grade:

-

automation

-

Output (kg/h):

-

180 - 600

-

Certification:

-

CE ISO

PC SHEET LINE

PET SHEET LINE

PP SHEET LINE

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

FINAL PRODUCTS

SANSU

- 15+ Years Professional Experience in R&D and Manufacturing Extrusion Line

Main characteristics of PET sheet:

High mechanical strength, rigidity and hardness. Good sliding performance and wear resistance, good electrical insulation, very good creep resistance, low and stable friction coefficient, excellent wear resistance (better than nylon), very good dimensional stability POM), physiologically inert (suitable for contact with food). It has good weather resistance and chemical resistance, low water absorption, and is resistant to weak acids and organic solvents, but it is not immersed in hot water or alkali.

Application areas of PET sheet:

Widely used in textile, papermaking, food machinery, transportation, terminal, medical, coal mine, chemical industry and other industries. Bearings, guides Food processing machine heads, pistons, screw rolls and other food jigs, parts, bearings for precision machines, electrical insulation materials, etc.

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

MACHINE DESCRIPTION

SANSU

- 15+ Years Professional Experience in R&D and Manufacturing Extrusion Line

Plastic PET Sheet Extrusion Line

.

★ The unit is mainly composed of a host, a screen changer, a mold, a tablet press, a conveyor, a tractor, a cutter, a stacker or a winder, etc .;

★ The gear box is made of cast steel, the gear is made of alloy steel and processed by gear grinding, and the lubrication points in the box are forced lubrication. The lubricating oil is equipped with an efficient water cooling system.

★ The screw material is made of 38CrMOA1A high-quality nitrided steel, after nitriding treatment, the surface is sprayed with alloy.

★ The barrel material is made of 38CrMOA1A high-quality nitrided steel, and after nitriding treatment, the surface is sprayed with alloy.

★ The raw materials that can be processed are: PET,PP, PE, PVC, PS, ABS, etc .;

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

PRODUCT DETAILS

SANSU

- 15+ Years Professional Experience in R&D and Manufacturing Extrusion Line

|

Plastic PET Sheet Extrusion Line

|

|

|

|

1. Single Screw Extruder

|

2. Filter changer with hydraulic station

|

|

|

3. Melting pump

|

4. PET T-die

|

|

|

5. Oblique rolling machine with three rollers

|

6. Haul off cooling stack with edge trimming

|

|

|

7. Circling water roller temperature controller

|

8. Winder

|

|

|

Model

|

SJ90/33

|

SJ120/33

|

SJ150/33

|

|

Max Output

|

240kg/h

|

350kg/h

|

450kg/h

|

|

Diameter

|

90mm

|

120mm

|

150mm

|

|

Motor power

|

75kw

|

110kw

|

132kw

|

|

Filter changer with hydraulic station

|

|

|

|

Material of filter plate

|

38CrMoAl

|

|

|

Diameter of filter plate

|

100mm

|

|

|

Change type

|

Hydraulic cylinder

|

|

|

Hydraulic station power

|

2.2KW

|

|

|

Melting pump

|

|

|

|

Model of melting pump

|

100CC

|

|

|

Rotating speed

|

<60rpm(adjustable)

|

|

|

Material of pump

|

M2

|

|

|

Output

|

Max 200Kgs/hr

|

|

|

Driving motor

|

5.5KW

|

|

|

PET T-die

|

|

|

|

Width of mould chasm

|

600mm-1500mm

|

|

|

Max. hatch of mould

|

producing sheeting with thickness 1.2mm

|

|

|

Min. hatch of mould

|

producing sheeting with thickness 0.2mm

|

|

|

Oblique rolling machine with three rollers

|

|

|

|

Driving system

|

Power of driving: Up roller: 1.5KW Mid roller:1.5KW Down roller:1.5KW

|

|

|

Specification of Roller

|

Diameter of Roller :Up roller:450mm

Mid roller:450mm Down roller:450mm

The surface of roller is quenched up to HRC45,quenching level:3-5mm

Chromeplate level for roller: t=0.10-0.15

The roller has screwy inner cavity, with 6 head.

|

|

|

Moving unit

|

The whole moving unit includes driving system, roller lifting unit, etc.

Power of Motor: 0.75KW Adopts bipolar gear down box to drive supply stable running. |

|

|

Electric control box

|

Separate electric control box with AC contactor of SIEMENS

Separate control of three rollers with inverter of ABB

|

|

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

MACHINE PARAMENTERS

SANSU

- 15+ Years Professional Experience in R&D and Manufacturing Extrusion Line

|

Model

|

Max Output

|

Diameter

|

Motor

power

|

Speed

adjuster

|

Material

|

Surface treatment

|

Rotation speed

|

|||||||

|

SJ120/33

|

400kg/h

|

120mm

|

132kw

SIMO DC motor

|

EUROTHERM DC Adjuster

|

38CrMoAlA

|

Nitrided and polished

|

20~90r/min

|

|||||||

|

SJ90/33

|

200kg/h

|

90mm

|

75kw

SIMO AC motor

|

ABB inverter

|

38CrMoAlA

|

Nitrided and polished

|

20~90r/min

|

|||||||

|

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

|

|

|

|

|

|

|

|

|||||||

ABOUT SANSU

SANSU

- 15+ Years Professional Experience in R&D and Manufacturing Extrusion Line

Sansu Machinery.

Sansu is manufacturer for kinds of plastic sheet extrusion machines, such as PET/PC sheet extrusion line, PE/PP/ABS sheet extrusion line, PP/PC hollow sheet line, PET infrared crystallized dryer,and established with excellent research and development team,Now we have 30000 sqm of factory and more than 60 employee,We have more than 10years production for kinds of plastic sheet extrusion line, such as PET PP PE ABS sheet machine. We always keep researching for new technology, and make complete process from recycling to sheet extrusion.

Our Advantages.

1. Experiences We have own R&D teams, engineers have more than 20 years experiences on plastic extrusion machine manufacturing, we are professional.

2. We use high quality materials for manufacture each machine.

3. Good and professional after-sales service not only include warranty period, for whole life of machine.

2. We use high quality materials for manufacture each machine.

3. Good and professional after-sales service not only include warranty period, for whole life of machine.

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

FAQ

SANSU

- 15+ Years Professional Experience in R&D and Manufacturing Extrusion Line

Q:What is acceptable payment terms?

A: T/T or L/C at sight

Q:Are you the manufacturer or trading company?

A: We are an industrial manufacture factory.we have independent technical team who focus on making machine; all the products are made by our technical team .

Q:How do you make the quotation for client?

A: Please offer the following information, so we can give you price and our advice as manufacturer:

Type of pipe you want to produce. Pipe diameter. Raw material and its types

A: T/T or L/C at sight

Q:Are you the manufacturer or trading company?

A: We are an industrial manufacture factory.we have independent technical team who focus on making machine; all the products are made by our technical team .

Q:How do you make the quotation for client?

A: Please offer the following information, so we can give you price and our advice as manufacturer:

Type of pipe you want to produce. Pipe diameter. Raw material and its types

If you can also send us photos of your samples, it would be highly appreciated.

Want to know more about SANSU plastic extrusion machinery, inquiry us without hesitate!

Hot Searches