- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2KW

-

Table Size:

-

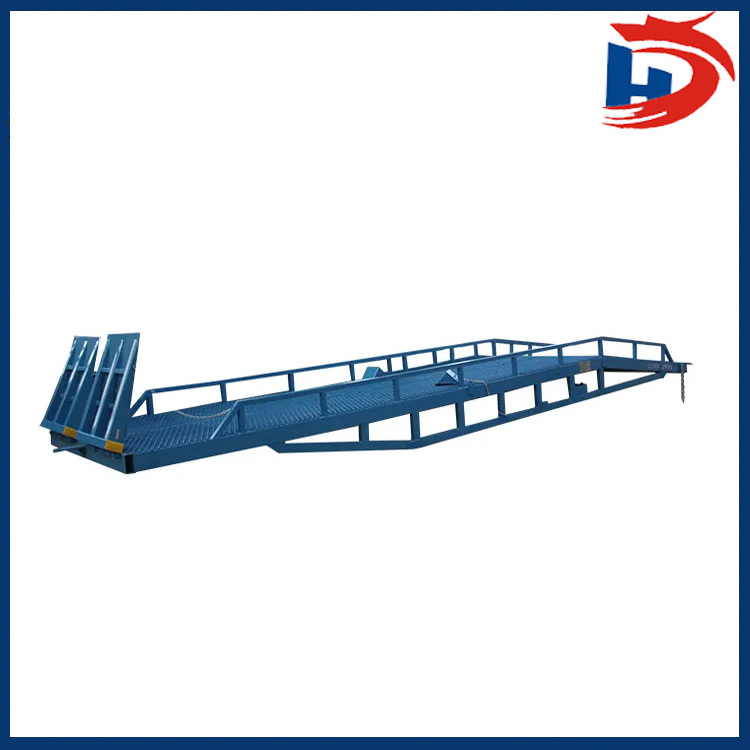

11300*2100MM

-

Overall Dimensions:

-

11300*2100*1100MM

-

Weight:

-

2400 kg

-

Machinery Test Report:

-

YES

-

Video outgoing-inspection:

-

YES

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

Outrigger, base, Hydraulic cylinder sleeve, Oil pipe, Valve block group, Filter screen, tank, Pressure gauge, Relief valve, Manual button

-

Product name:

-

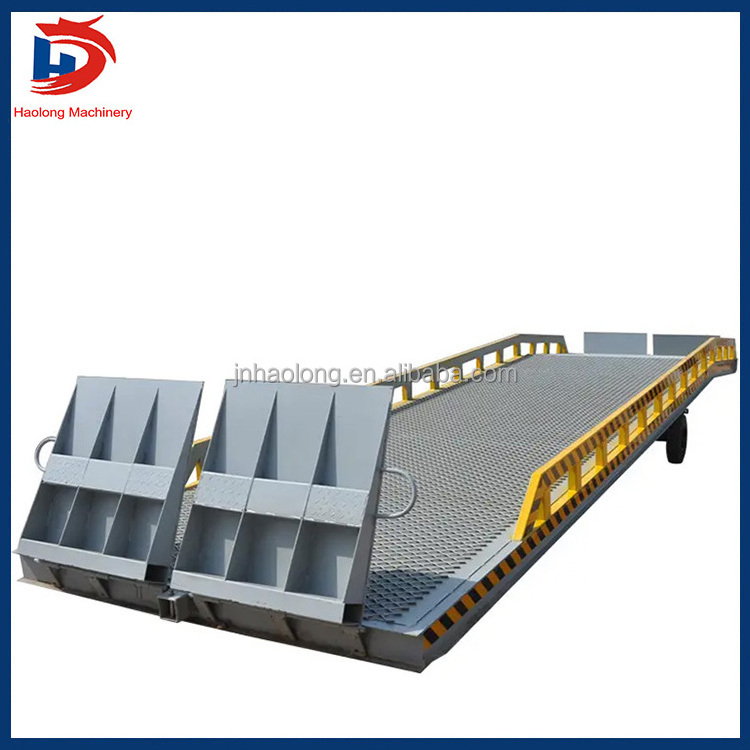

Mobile boarding bridge

-

Color:

-

Blue

-

Platform size:

-

11300*2100*1100mm

-

Warranty period:

-

1 year

-

deadweight:

-

2400 tons

-

bearing:

-

8t

-

Adjusting height:

-

1100-1800mm

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HL

-

Power:

-

2.2KW

-

Table Size:

-

11300*2100MM

-

Overall Dimensions:

-

11300*2100*1100MM

-

Weight:

-

2400 kg

-

Machinery Test Report:

-

YES

-

Video outgoing-inspection:

-

YES

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

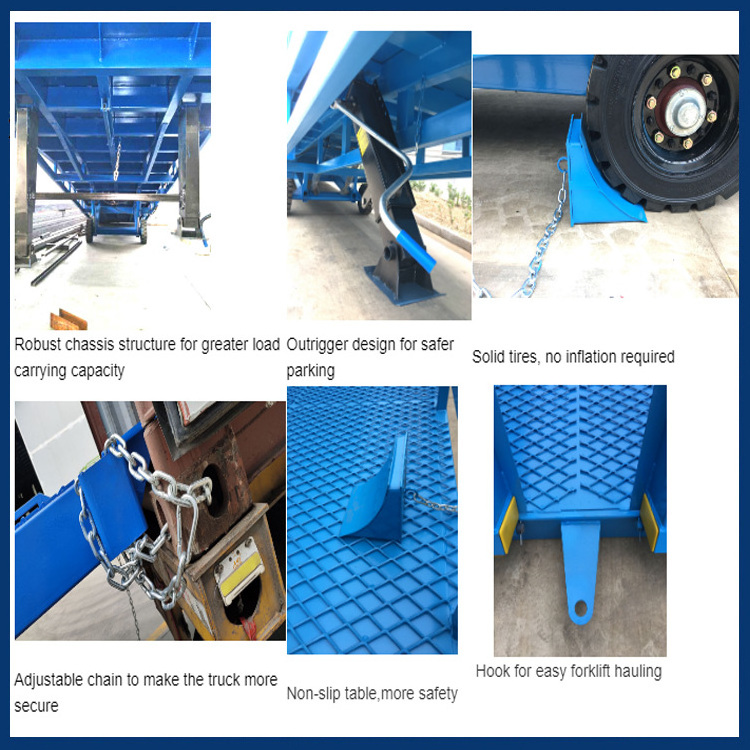

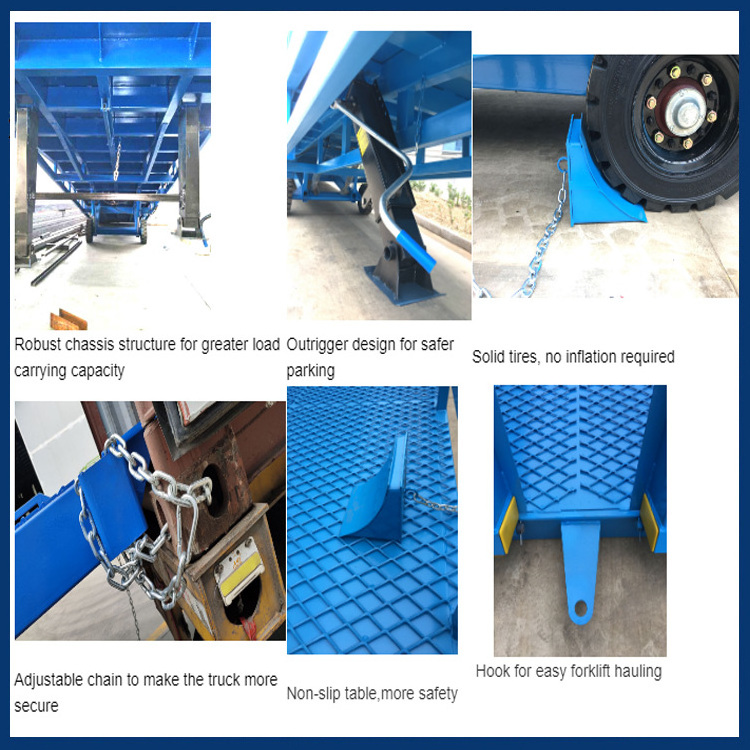

Outrigger, base, Hydraulic cylinder sleeve, Oil pipe, Valve block group, Filter screen, tank, Pressure gauge, Relief valve, Manual button

-

Product name:

-

Mobile boarding bridge

-

Color:

-

Blue

-

Platform size:

-

11300*2100*1100mm

-

Warranty period:

-

1 year

-

deadweight:

-

2400 tons

-

bearing:

-

8t

-

Adjusting height:

-

1100-1800mm

1.Port terminal: It can be used for the transportation of goods and personnel between the terminal and ships.

2. Offshore oil platforms: can be used for the transportation of goods and personnel between oil platforms and ships.

3. Military base: It can be used for the transportation of goods and personnel between military bases and ships.

In short, the mobile boarding bridge is a very important device that can conveniently connect ships and docks, improve the transportation efficiency of goods and personnel, reduce labor intensity, and have broad application prospects.

With the continuous progress of technology and equipment upgrades, the performance and functionality of mobile boarding bridges will continue to improve, bringing more convenience to our production and life.

|

Load capacity

|

Overall size

|

deadweight

|

Factory quotation (USD)

|

Lifting method

|

|

8T

|

2100*11500*1100mm

|

25000kg

|

2950

|

Manual hydraulic lifting

|

|

10T

|

2100*11500*1100mm

|

2610kg

|

3100

|

Manual hydraulic lifting

|

|

12T

|

2200*11500*1100mm

|

2910kg

|

3300

|

Manual hydraulic lifting

|

|

15T

|

2200*11800*1200mm

|

3200kg

|

3800

|

Electric manualhydraulic lifting

|

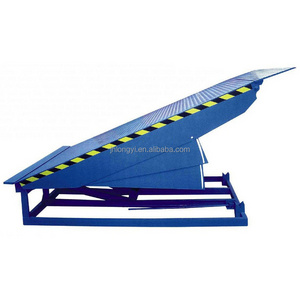

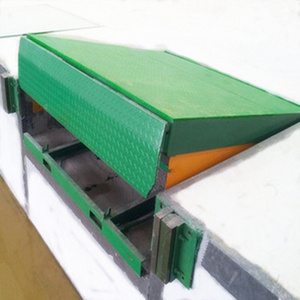

quay ramp

The dock ramp is used in places where there is no loading and unloading platform on site or where mobile loading and unloading of goods are required. If there is no loading and unloading platform at the logistics site, as a remedial measure, the mobile boarding bridge is equivalent to a moving steel structure slope, and forklifts can also directly drive into the truck carriages for batch loading and unloading operations. Only one person is required to operate without the need for power supply, which can achieve safe and fast loading and unloading of goods.

Mobile boarding bridge structure

Mobile boarding bridge structure: The mobile boarding bridge is composed of a mechanical system, a hydraulic system, and an electrical system. The platform and chassis form a mechanical system. The platform is made of "U" shaped steel as the skeleton, with light self weight and large bearing capacity; The countertop is made of anti slip patterned steel plates and has a high load-bearing capacity; The countertop is made of anti slip patterned steel plates, and can withstand a speed of 10 kilometers/hour when the forklift is fully loaded without bending, improving work reliability.

Usage of mobile boarding bridge

(1) Firstly, park the vehicle that needs to be moved in a suitable position, then turn on the power switch to start the engine and shift the gear to neutral. At this time, the hydraulic device starts to work normally. After the hydraulic pressure reaches a certain pressure, release the hand brake pedal and allow the wheels to rotate to achieve the transfer of goods.

(2) When there are other tasks that need to be transported, the handle in the driver's cab can be pulled forward or backward, or the corresponding mode can be selected according to the actual situation to control the vehicle's steering angle to complete the corresponding task.

(3) If it is necessary to stop using for a long time, please turn off the main power switch to avoid accidental losses.

(4) In case of special circumstances when cutting off the main power supply, the positive wire of the battery should be disconnected first and then the negative wire to prevent personal injury caused by high voltage electricity.

(5) As this product belongs to the category of special machinery, overloading should be avoided during daily use to ensure driving safety!

Mobile boarding bridge

The mobile boarding bridge is a very important device that can connect ships and docks, making it easy for goods and personnel to

enter and exit the ship. This type of equipment has a wide range of applications, not only for ports and docks, but also for

offshore oil platforms, military bases, and other places.

enter and exit the ship. This type of equipment has a wide range of applications, not only for ports and docks, but also for

offshore oil platforms, military bases, and other places.

1. Structural composition of mobile boarding bridge

(1) Outrigger: It is composed of column and diagonal brace (commonly known as girder) to support the weight of the whole support and adjust the height to meet the needs of different models. (Generally, welding is used).

(2) Bracket: used to fix the positional relationship between the cargo box and the chassis.

(3) Base: (also known as base), which is installed on the ground to ensure the stable and reliable operation of the entire equipment;

(4) Hydraulic cylinder sleeve: located in the hydraulic oil circuit system to play a sealing role;

(5) Oil pipe: connecting the pipelines between various components and between the hydraulic pump station and the oil tank;

(6) Valve block group: controls the flow rate of hydraulic oil.

(7) Filter screen: filter impurities and dust in hydraulic fluid;

(8) Fuel tank: stores all liquid fuel during use;

(9) Pressure gauge: indicating the working status of the operator;

(10) Relief valve: protects the safe operation of the hydraulic system.

(11) Manual button: Convenient for workers to perform various operational actions.

Advantages

The mobile boarding bridge has the following advantages:

1. It is easy to operate and control, and can achieve remote control.

2. It can adapt to ships of different heights and has good adaptability.

3. It has good load-bearing capacity and stability, ensuring the safety of goods and personnel.

4. It can adapt to different docks and ships, and has good universality.

5. It can reduce the labor intensity between the dock and the ship, and improve work efficiency.

6.

When the ship approaches the dock, the mobile boarding bridge will be raised, and a bridge connection will be established between the ship and the dock, making it convenient for goods and personnel to enter and exit the ship.

Mobile boarding bridge structure

The mobile boarding bridge consists of a bridge body, a bracket, a hydraulic system, an electrical system, and a control system.

The bridge body is composed of multiple membrane structural plates spliced together, which has good load-bearing capacity and wind resistance.

The bracket is composed of multiple hydraulic supports, which can adjust the height and horizontal direction of the bridge body.

The hydraulic system is composed of motors, oil pumps, hydraulic cylinders, etc., which can control the lifting and horizontal movement of the bridge body.

The electrical system mainly includes motors, switches, cables, etc., which can control the operation of the hydraulic system.

The control system is composed of a PLC controller, touch screen, etc., which can control the operation and monitoring of the entire system.

Hot Searches