- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V,50HZ,3P

-

Power:

-

308000

-

Dimension(L*W*H):

-

14100*7800*11000mm

-

Weight (KG):

-

20000

-

Product name:

-

ZPG Series extractum Centrifugal Spray Drier

-

Capacity:

-

200-270Kg/h

-

Solid content in wet products:

-

10-30%

-

Water content in final product:

-

1-3%

-

Air temperature at inlet:

-

150-200℃

-

Air temperature at outlet:

-

80-100℃

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

CONOVAL

-

Voltage:

-

380V,50HZ,3P

-

Power:

-

308000

-

Dimension(L*W*H):

-

14100*7800*11000mm

-

Weight (KG):

-

20000

-

Product name:

-

ZPG Series extractum Centrifugal Spray Drier

-

Capacity:

-

200-270Kg/h

-

Solid content in wet products:

-

10-30%

-

Water content in final product:

-

1-3%

-

Air temperature at inlet:

-

150-200℃

-

Air temperature at outlet:

-

80-100℃

Product Description

ZPG series of spraying and drying machine for Chinese medical extract

Brief introduction:

In this machine, the fully-closed structure is adopted, all parts are made of stainless steel, and there is

the 3-stage purifying device. After the filtering, the air meets the 100000-grade standard. There are cooling devices for the

reactor, the temperature of the container wall is less than 80℃, and even the raw products are stayed on the wall, will not be burned. The powder rate is as high as more than 95%, and there is no powders mixing or wall hanging.

the 3-stage purifying device. After the filtering, the air meets the 100000-grade standard. There are cooling devices for the

reactor, the temperature of the container wall is less than 80℃, and even the raw products are stayed on the wall, will not be burned. The powder rate is as high as more than 95%, and there is no powders mixing or wall hanging.

Working principle:

In this machine, the centrifugal spraying and drying technology is adopted. With the high-speed centrifugal atomizer, after the spraying, powders are atomized, can be contacted with hot air completely, and the drying is completed instantly.

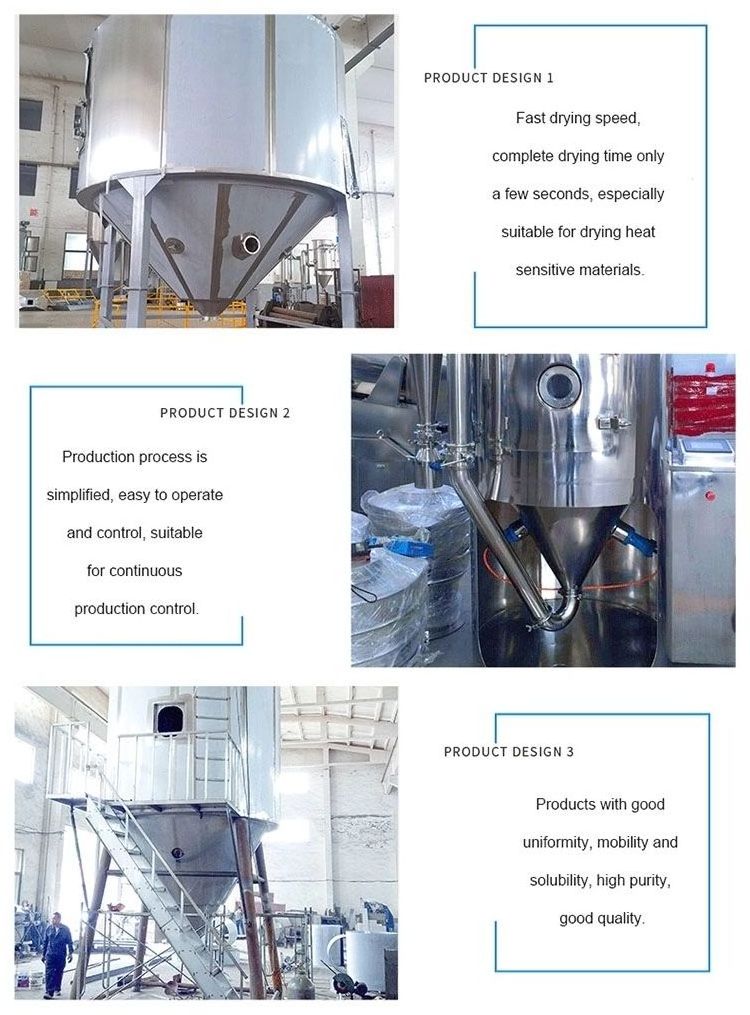

Details Images

Feature:

1.With the 3-stage purifying device, the air meets the 100000-grade standard.

2.There are cooling devices for the reactor, the temperature of the container wall is less than 80℃, and even the raw products are stayed on the wall, will not be burned.

3.With the flushing device, the machine can be applied for the drying for many kinds of products.

4.The wet-type dust collecting is adopted, which meets the environment protecting standard.

5.There is the air cleaning device.

6.In the atomizer, the variable-frequency speed regulating is equipped.

7.There is the touch screen and the PLC.

8.CIP

3.With the flushing device, the machine can be applied for the drying for many kinds of products.

4.The wet-type dust collecting is adopted, which meets the environment protecting standard.

5.There is the air cleaning device.

6.In the atomizer, the variable-frequency speed regulating is equipped.

7.There is the touch screen and the PLC.

8.CIP

Specification

|

S.N.

|

Items

|

Requirement

|

|

1

|

Raw product

|

Concentrated liquid from fruit puree

|

|

2

|

Air temperature at inlet

|

150 ~ 200℃

|

|

3

|

Air temperature at outlet

|

80 ~ 100℃

|

|

4

|

Dewatering

|

90Kg/h

|

|

5

|

Water content in raw product

|

80 ~ 90%

|

|

6

|

Water content in final product

|

1 ~ 3%

|

|

7

|

Heating

|

Electric heating: 210Kw / Natural gas: 220m2

|

|

8

|

Electric high-speed centrifugal atomizer

|

1 set

|

|

9

|

Vibrator for tower wall

|

3pcs

|

|

10

|

Total power

|

38.25Kw (Electric heating of 270Kw is not included)

|

|

11

|

Gas furnace(optional)

|

600000kilocalorie

|

|

12 |

Material |

Stainless steel 304

Thickness of inner plate in the drying tower: 3mm Insulation: 80mm Outer seal: 1.2mm (Stainless steel 304) |

Notes:If any change of data, we will not notify further

Packing & Delivery

Hot Searches