The original rear pick-up feeder technology taken from the offset Press, ensures stable and smooth feeding of various types of

substrate. Dependant on the substrate, overlapped (stream) or single sheet (universal) fed can be selected easily. A front pick up

feeder is also available and can be used for stable feeding of film and other substrates.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYAL PACKING

-

Dimensions(L*W*H):

-

3.15 * 1.68 * 1.3m

-

Weight:

-

1500 KG

-

Certification:

-

CE

-

Max. Print Area:

-

1020 x 700mm

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

380

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYAL PACKING

-

Dimensions(L*W*H):

-

3.15 * 1.68 * 1.3m

-

Weight:

-

1500 KG

-

Certification:

-

CE

-

Max. Print Area:

-

1020 x 700mm

Product Description

Introduction:

Full Automatic Stop Cylinder Screen Press adopts the classical stop cylinder technology with the advantages such as: paper located exactly and steadily, high precision, high speed, low noise, high degree automatization and so on, it is suitable for printing on ceramic and glass applique, electron industry (film switch, flexible circuitry, meter panel, mobile telephone), advertisement, packing and printing, brand, textile transfer, special technics etc.

Which is the newest product of flat feed cylinder screen press.

Standard Euipment installed

Rear pick-up feeder

Pull/push convertible side lays (with detecting sensor)

Cylinder bulit-in front lay sensor

Side lay sensor

Double sheet detector

Screen frame pneumatic lock clamp

Temporary stop quick adjustment device

Sunction feed belt

Delivery board lowering system

Squeegee printing pressure kept device

Automatic lubricate device

Partial Detail

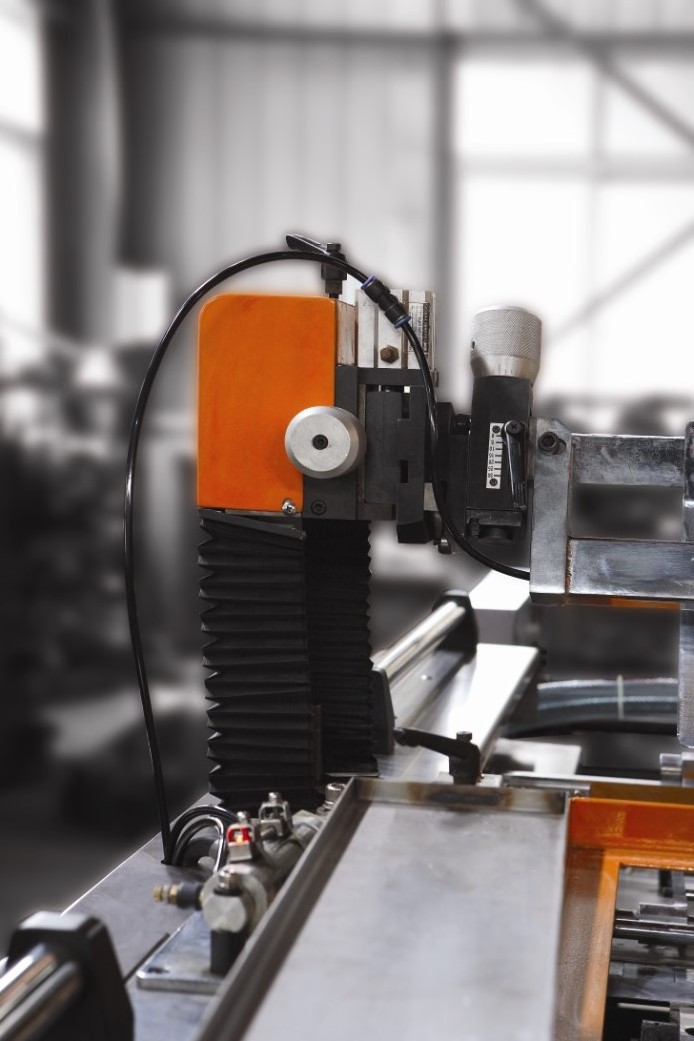

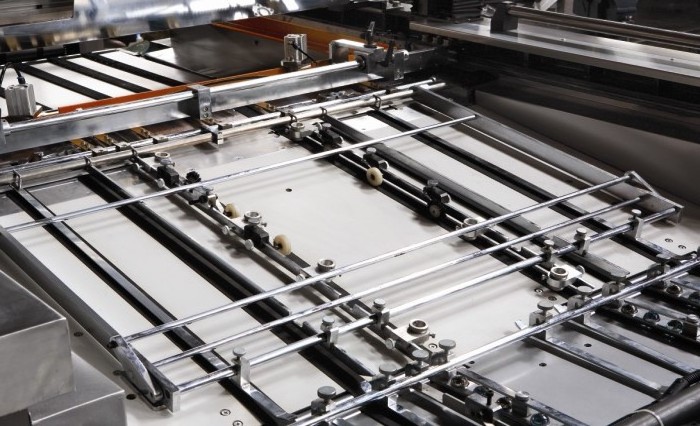

Feeder

Feed board

The vaccum absorb is assembled in the bottom of the feed board, matching with the push and press paper construction, insure

various materials all can be delivered smoothly.

various materials all can be delivered smoothly.

Cylinder and registeration system

Cylinder stops step automatically to ensure the forehead of the printing stock can be sent accurately to the gripper of cylinder,

which is up to extreme high precision; at the same time, gripper of cylinder and pull side-lay both have sensors for supervising

if the printing stock is in correct place. The vacuum cylinder with +/- 0.01mm accuracy across the cylinder surface, a large

cylinder shaft and specially made high precision bearings ensure the highest quality printing at higher speed.

which is up to extreme high precision; at the same time, gripper of cylinder and pull side-lay both have sensors for supervising

if the printing stock is in correct place. The vacuum cylinder with +/- 0.01mm accuracy across the cylinder surface, a large

cylinder shaft and specially made high precision bearings ensure the highest quality printing at higher speed.

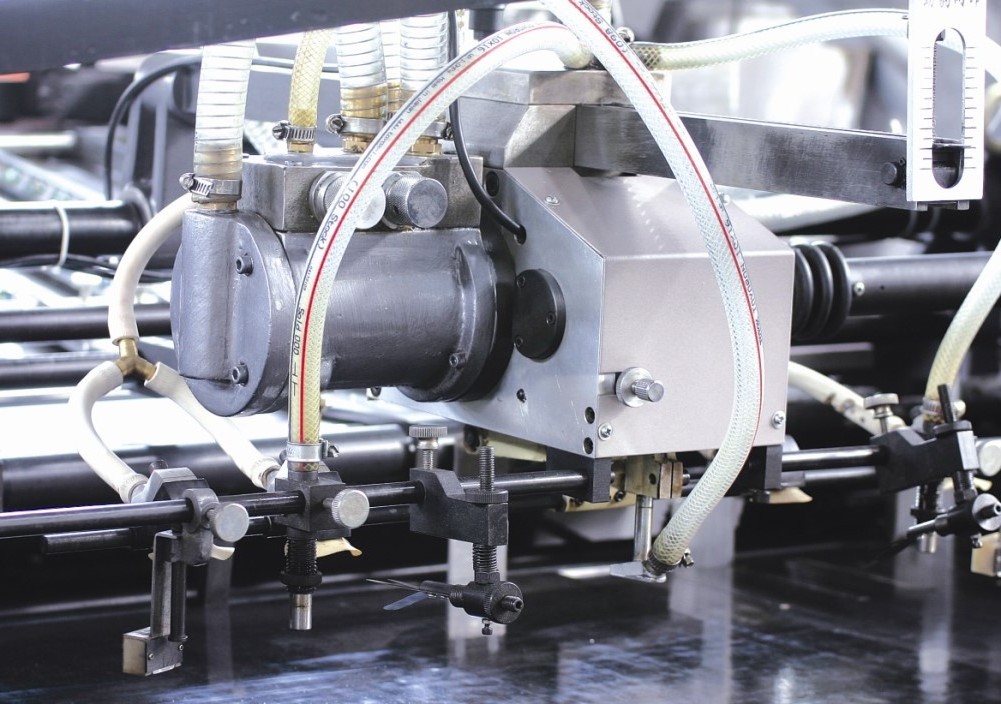

Squeegee system

Squeegee and ink return bladeare driven by individual cams and a two-step action cam helps reduce the squeegee shock onto the

screen mesh; Due to the positive down cam action, the printing pressure is evenly applied to the cylinder continuously, squeegee

with the pneumatically pressure kept device, resulting in sharp dot reproduction, the printing graphics is more clearly and the

ink layer is more well-proportioned.

screen mesh; Due to the positive down cam action, the printing pressure is evenly applied to the cylinder continuously, squeegee

with the pneumatically pressure kept device, resulting in sharp dot reproduction, the printing graphics is more clearly and the

ink layer is more well-proportioned.

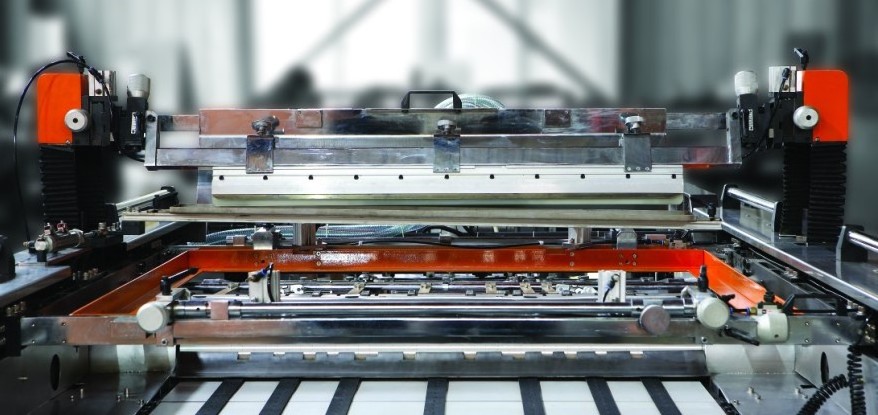

Frame circulate railway

Imported beeline guide and ball bearing, reduce the shake and noisy when the whole machine is working under high speed, insure the

stability of printing.

Delivery board

The delivery board can be overturned up to 90degree to allow easy access to the screen mesh for cleaning and adjusting the frame,

installing the blade; along with the vacuum adsorption, insure collection smoothly.

Screen Frame System

The screen frame rack can be pulled out, which is easy for adjusting the register or feeding, as well as cleaning the cylinder and

screen frame; at the same time, it is assembled with device to hold the ink dropped to avoid the ink drops on the cylinder.

screen frame; at the same time, it is assembled with device to hold the ink dropped to avoid the ink drops on the cylinder.

UV Curing machine is specially designed for using with automatic screen printing machine, offset machine and other equipments. It's widely used for dying,dehumidifying and UV curing etc in the field of screen printing, printing and dyeing,electroplating, electronic circuit board and so on.

Main features:

1、Three groups of UV lamps are independently. There are three choice for the UV intensity separately are half,3/4 and full power, which can prolong the life of the lamp and save energy. The digital meter shows the ligt intensity and using life timely.

2、The cover is used special aluminium-magnesium alloy, designed as light gathered, which can get high production efficiency.

3、Equipped with a reasonable cooling systems(the upper and lower sets) to prevent the temperature of work chamber to be overtop and leading the printing stock to be deformation

4、It has conveyor belt rectify a deviation system with adsorption,more conductive to delivery thin paper; adopt imported high temperature resistant and rub resistant"TEFION" belt which ensure to use for long time and stably

5、Conveyor belt is adjusted stepless, the speed can be adjusted under the specific situation, the top speed can be up to 44m/minute.

Full Automatic Stacker

Full automatic stacker can combine with full-automatic cylinder type screen press and all kinds of dryer together to collect the paper and make them in order automatically.

Main feature:

1.The whole machine is controlled by PLC, collecting printing substrate and making the paper in order automatically.

2. Photoelectricity monitoring,two sides of baffles run when the paper come into the plate.

3.Paper conveying system is controlled by inverter with stepless speed regulation and conveyor belt guide the idler wheel to feed the paper.

4.Pneumatical elements control the jogger action, which avoid paper to be broken or other damage.

5.Following all kinds of paper size, paper jogging device can be adjusted from back, left and right easily and conveniently.

6.Induction sensor make the stacking board down automatically and keep paper collect smoothly.

7.Paper stacker has limitation safety mechanism at up and down position to avoid the machine from damaged.

8.Paper jam and paper pile height supervision and make the printing press stop in-line.

9.Connected with the printing part which can control the printing part's running.

10.Paper counting function.

Machine Photos

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Printing Shops, Other, paperboard factory, cardboard factory, corrugated paperboard factory

|

|

Showroom Location

|

None

|

|

Condition

|

New

|

|

Type

|

flexo printing machine

|

|

Place of Origin

|

China

|

|

Weight

|

800kg

|

|

Warranty

|

1 Year

|

|

Production Capacity

|

Other

|

|

Key Selling Points

|

High-accuracy

|

|

Max. workable width

|

Other

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

3 months

|

|

Core Components

|

Motor, Other, Bearing, Engine, PLC

|

|

PLC Brand

|

Omron, Siemens

|

|

|

|

Recommend Products

FAQ

1. who are we?

We are based in Zhejiang, China, start from 2021,sell to Mid East(40.00%),South America(10.00%),South Asia(5.00%),Central America(5.00%),Western Europe(5.00%),North America(5.00%),Eastern Asia(5.00%),Oceania(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%),Northern Europe(3.00%),Domestic Market(1.00%),Southern Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Corrugated Paperboard Production Line,Single Facer Line,Flexo Printing Machine,Folder Gluer Machine,Flute Laminating Machine

4. why should you buy from us not from other suppliers?

We have our own factory in China. We have high quality employee team, special engineers, and special operators for export work of machines.And we have our Sales branch In Amman city, Jordan.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,German,Arabic,Russian

We are based in Zhejiang, China, start from 2021,sell to Mid East(40.00%),South America(10.00%),South Asia(5.00%),Central America(5.00%),Western Europe(5.00%),North America(5.00%),Eastern Asia(5.00%),Oceania(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%),Northern Europe(3.00%),Domestic Market(1.00%),Southern Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Corrugated Paperboard Production Line,Single Facer Line,Flexo Printing Machine,Folder Gluer Machine,Flute Laminating Machine

4. why should you buy from us not from other suppliers?

We have our own factory in China. We have high quality employee team, special engineers, and special operators for export work of machines.And we have our Sales branch In Amman city, Jordan.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,German,Arabic,Russian

Hot Searches