- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

New

-

Power (kW):

-

75 kW

-

Weight (KG):

-

17500 KG

-

Application:

-

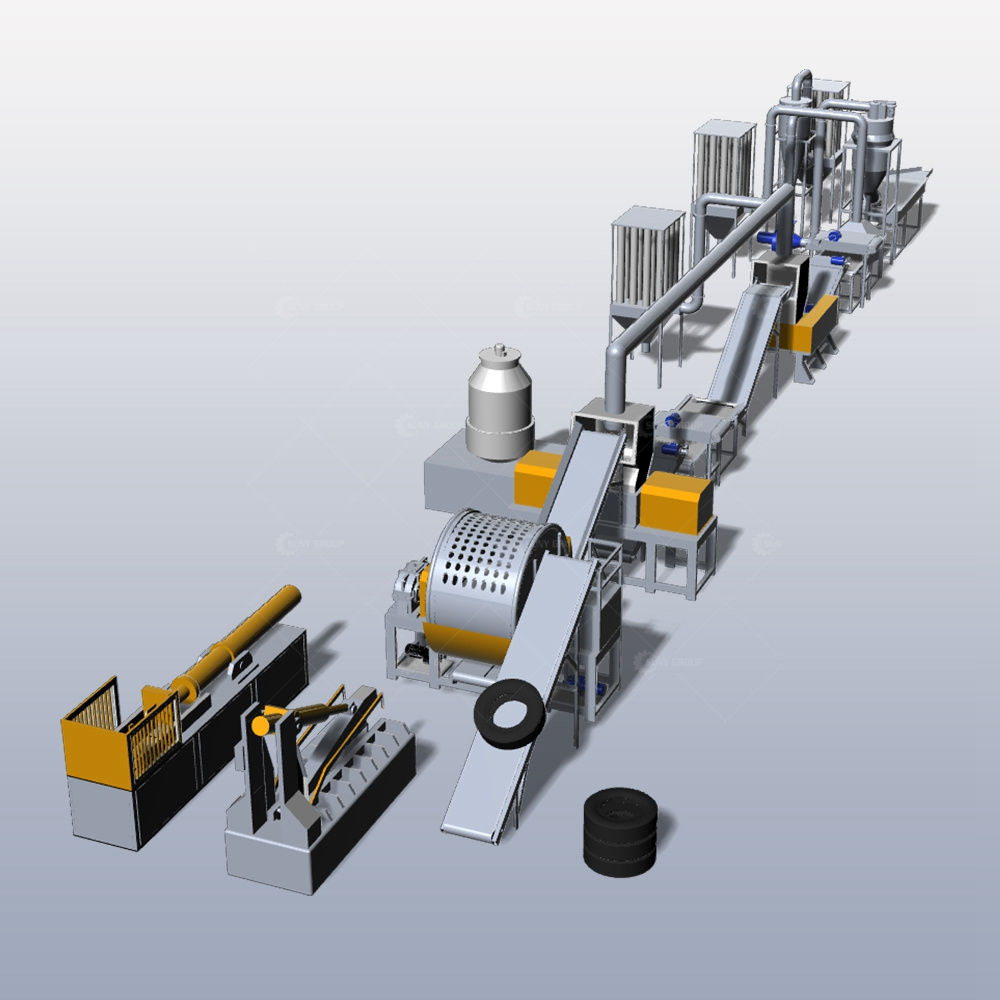

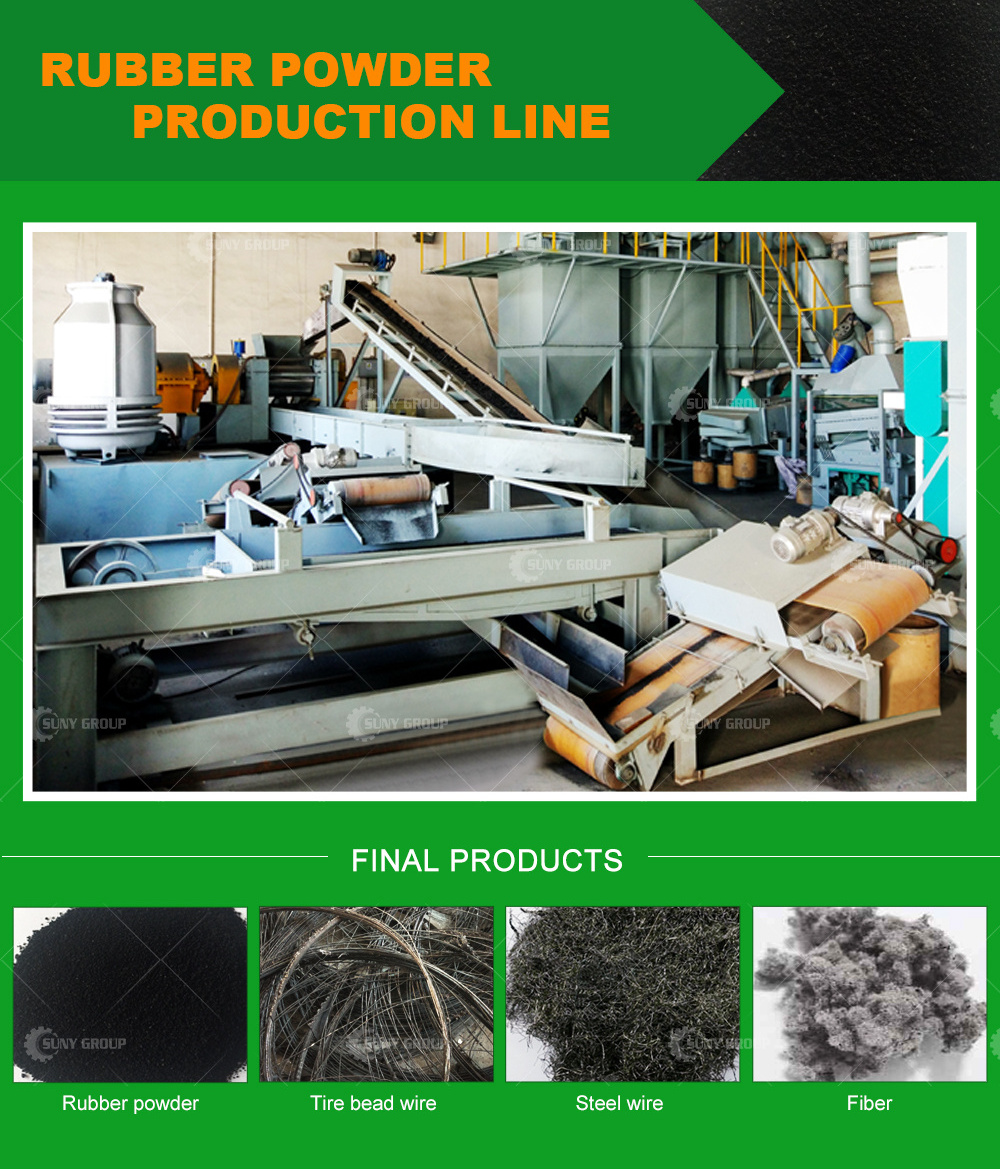

Rubber Powder Production Line

-

Capacity:

-

100-1000KG/H

-

Usage:

-

Crush the whole tyres into small pieces 3-8cm blocks

-

Name:

-

Tire shredder

-

Fiber removal ratio:

-

98%

-

Oprerator:

-

2-4 persons

-

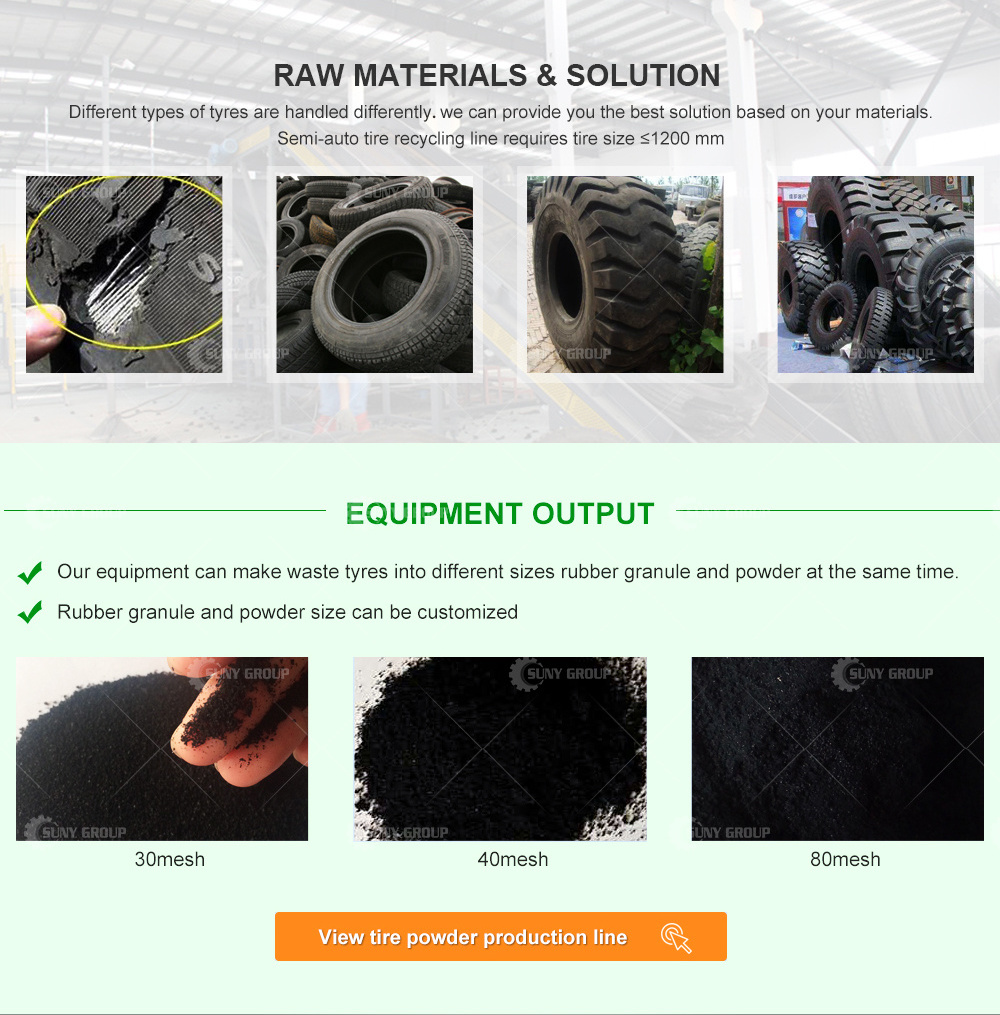

Raw material:

-

Waste Tyre

-

Function:

-

Waste Tire Recycling Equipment

-

Grinding chanber:

-

Open structure

-

Speed reducer:

-

Hard-toothed surface reducer

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Sunygroup

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

3500*3200*2800mm

-

Year:

-

New

-

Power (kW):

-

75 kW

-

Weight (KG):

-

17500 KG

-

Application:

-

Rubber Powder Production Line

-

Capacity:

-

100-1000KG/H

-

Usage:

-

Crush the whole tyres into small pieces 3-8cm blocks

-

Name:

-

Tire shredder

-

Fiber removal ratio:

-

98%

-

Oprerator:

-

2-4 persons

-

Raw material:

-

Waste Tyre

-

Function:

-

Waste Tire Recycling Equipment

-

Grinding chanber:

-

Open structure

-

Speed reducer:

-

Hard-toothed surface reducer

-

Marketing Type:

-

Hot Product 2022

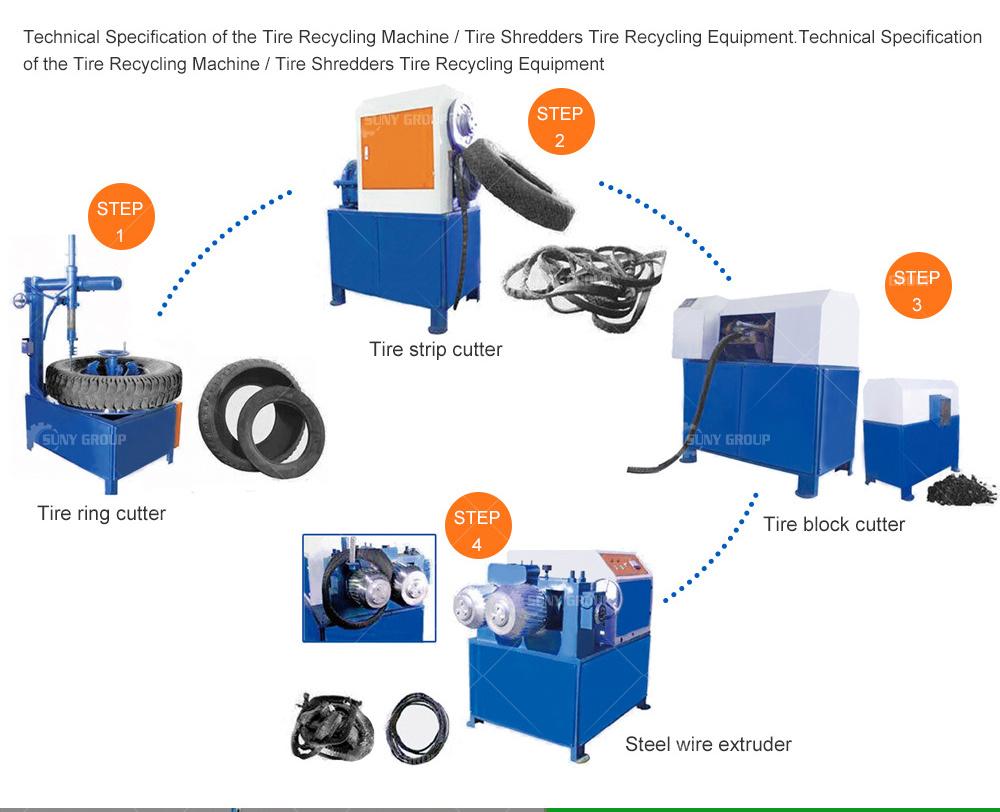

WORKING PROCESS

Operation:

Put tire on the round platform, rotate the wheel to make the four claws catch inside of tire and fix steady, startthe power supply, the platform start to rotary, handle the cutting knife control stick, leading the knife cut into tireadjust the cutting depth until the tire sidewall cut off.

Features:

Reasonable design, stable performance, high quality, ease operation, long service life, low noise, no polltion,an ideal equipment for tire recycling.

The adjustment of rubber strip width:

There is a guiding rule in the middle of the two blades and the rubber strip width is up to the distance betweenthe guiding rule and blade. The distance means the rubber strip width. The guiding rule can be adjusted by theleft and right movement of the two screw rods.

The blade maintenance:

When the blade is not sharp, sharpen the blades with angle grinder. When sharpening the blades, the grindingwheel shall not focus on one position for a long time.When changing the blades, remove the lower blade firstand then remove the upper blade; when installing the blades, fix the upper blade first and then fix the lowerblade.

The machine Maintenance:

1.check the motor if the default phase happens or if the short circuit happens, and check if the change-overswitch works normally;

2.check the gearbox and big gears if they are short of oil;

3.the two blades are connected by two main shafts and each main shaft is supported and fixed by two sets ofbearings.Check the bearing if the lubricating oil is short.

Application:

The rubber block cutter is used to cut rubber strips into 3--5cm blocks for grinding into rubber powder or rubbergranule in the next step.

Operation:

Start the power, put tire strips into the feeder,and then strips will be cutted into 3-5cm rubber blocks.

Application:

This steel wire extruder is mainly used to separate the rubber and steel wire from the tire bead of all kinds oftires and you can get a complete steel wire ring.

Operation:

Start the power, put tire bead into the rollers of the steel wire extruder and then start the button to make the tirebead enter the rollers. After separating the rubber and steel wire, start the button to make the tire bead get outof the rollers, and then take out the tire bead from the rollers, so you get a complete steel wire ring.

Features:

Easy operation and maintenance, high separation efficiency.

Hot Searches