- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

XPS foam board machine

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

80m*15m*6m

-

Power (kW):

-

500

-

Weight:

-

10000 KG

-

Capacity:

-

200-2000kg/hr

-

Thickness of boards:

-

20mm -200mm

-

Width of boards:

-

600mm/1200mm

-

Foaming agent:

-

CO2/Freon/Alcohol/Butane/LPG/DME

-

Quantity of workers:

-

5

-

Color of machine:

-

Blue/Green/Your choice

-

Automatic Grade:

-

Fully automatical

-

Certification:

-

CE

-

Power:

-

350/700/1400kw

-

Marketing Type:

-

Hot Product 2023

Quick Details

-

Screw Design:

-

Double screw + Single screw

-

Screw L/D Ratio:

-

33:1

-

Screw Speed (rpm):

-

90 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

XPS foam board machine

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

80m*15m*6m

-

Power (kW):

-

500

-

Weight:

-

10000 KG

-

Capacity:

-

200-2000kg/hr

-

Thickness of boards:

-

20mm -200mm

-

Width of boards:

-

600mm/1200mm

-

Foaming agent:

-

CO2/Freon/Alcohol/Butane/LPG/DME

-

Quantity of workers:

-

5

-

Color of machine:

-

Blue/Green/Your choice

-

Automatic Grade:

-

Fully automatical

-

Certification:

-

CE

-

Power:

-

350/700/1400kw

-

Marketing Type:

-

Hot Product 2023

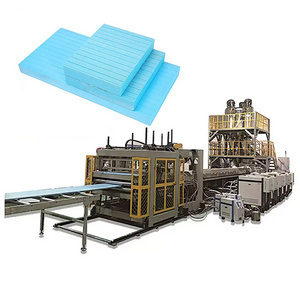

XPS FOAM BOARD MAKING MACHINE

1. TECHNICAL SPECIFICATION OF XPS BOARD EXTRUSION LINE

| Product | XPS CO2 Extrusion Line | Model |

75/32-200,90/32-300 |

| Board width | 600-1200mm | Board thickness | 20mm--120mm |

| Output |

500 - 1000 kg/h or 350 - 800 m 3 /24h |

Density | 28 - 40 kg/ m 3 |

| Blowing agent | CO2+Alcohol | Material | Polystyrene(PS) |

| Certificate | ISO 9001: 2000 | ||

| Function | produce Extruded Polystyrene (XPS) Foam Board | ||

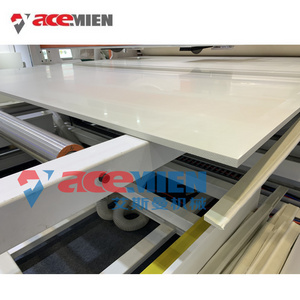

2. Standard configuration OF XPS BOARD EXTRUSION LINE

|

Description |

|

Extrusion feed system |

|

Main extrusion system |

|

TDS75D twin screw extruder |

|

Melt adaptor |

|

TDD200R single screw extruder |

|

High pressure blowing agent injection system |

|

Dosing unit for SCF CO2 |

|

Dosing unit for HCFC or HFC blends |

|

Static mixer and Die |

|

Static mixer |

|

Die |

|

Central control station |

|

Calibrator and haul-off |

|

Calibrator |

|

Haul-off |

|

Cooling section |

|

Puller and edge cut hogging units |

|

Main cut-off machine |

|

Roller conveyor |

|

Side and end milling sections |

|

Length-side milling section |

|

End-trim milling section |

|

Stacker and lifter |

|

Auto-packing unit |

|

XPS Recycle Line |

|

Reversal Cooling Rack |

|

Crusher blowing and air purification system |

3. PICTURES OF XPS BOARD EXTRUSION LINE

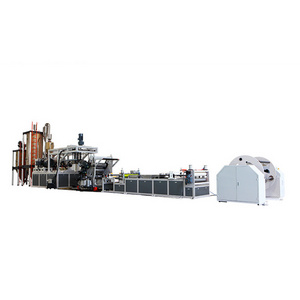

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.