- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Laien

-

Voltage:

-

380v or customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

11000

-

Name:

-

electrostatic painting line

-

Material:

-

Higher Quality Standard Steel, PP panel

-

Usage:

-

painting metal fence

-

Color:

-

Required

-

Coating Technology:

-

Fully Automatic Spraying

-

Coating color:

-

Multi Color

-

Advantage:

-

Control Temperature Automatically

-

Keywords:

-

Spray Powder Line

-

Spraying Guns:

-

Automatic Powder Spray Gun

-

Spraying method:

-

Robot Automatic Spray

Quick Details

-

Machine Type:

-

powder coating line, Spray Booths, Painting Equipment, Curing oven, Coating Equipment

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Laien

-

Voltage:

-

380v or customized

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

11000

-

Name:

-

electrostatic painting line

-

Material:

-

Higher Quality Standard Steel, PP panel

-

Usage:

-

painting metal fence

-

Color:

-

Required

-

Coating Technology:

-

Fully Automatic Spraying

-

Coating color:

-

Multi Color

-

Advantage:

-

Control Temperature Automatically

-

Keywords:

-

Spray Powder Line

-

Spraying Guns:

-

Automatic Powder Spray Gun

-

Spraying method:

-

Robot Automatic Spray

Product Description

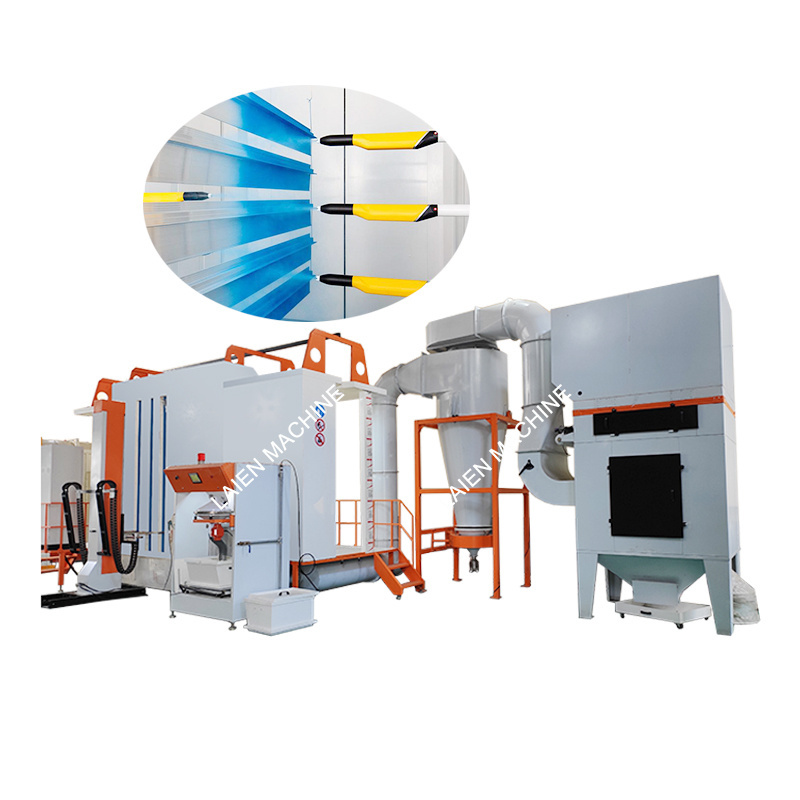

Powder Coating Line

The design of the automatic spraying line reduces a lot of labor. It mixes the powder with air in the powder feeder and sends it

to the powder spray gun. The high voltage generated by the high-voltage electrostatic generator is connected to the inside or

front end of the powder spray gun. The inside or outlet of the powder spray gun is charged, and under the combined action of air

force and electrostatic force, the powder particles are sprayed on the workpiece to be coated in a directional direction. Safety

and environmental protection, high output, high efficiency, uniform coating.

to the powder spray gun. The high voltage generated by the high-voltage electrostatic generator is connected to the inside or

front end of the powder spray gun. The inside or outlet of the powder spray gun is charged, and under the combined action of air

force and electrostatic force, the powder particles are sprayed on the workpiece to be coated in a directional direction. Safety

and environmental protection, high output, high efficiency, uniform coating.

PVC Coating Line Basic technical parameters:

|

Type

|

PVC Coating Line

|

|

Substrate

|

metal

|

|

Condition

|

New

|

|

Machine Type

|

powder coating machine

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

New Product 2020

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC

|

|

Coating

|

powder coating

|

|

heat Energy

|

Electricity,natural Gas

|

|

Temperature

|

180-200degree

|

|

Heating time

|

30 Min

|

|

Drying Time

|

15-20min

|

|

Effective Heating Length in Furnace

|

50m

|

|

Air cycle times

|

2-3 times

|

|

Temperature Difference

|

+-5℃

|

|

keywords

|

PVC coating production line

|

|

Spraying Guns

|

auto spray gun

|

1. The corrosion resistance of the coating is very good and uniform coating

2. The powder coating does not contain solvents and has no pollution from three wastes, which improves labor and hygiene conditions.

3. Adopting new technology such as powder electrostatic spraying, high efficiency, suitable for automatic assembly line

coating, high powder utilization rate, and recyclable.

3. Adopting new technology such as powder electrostatic spraying, high efficiency, suitable for automatic assembly line

coating, high powder utilization rate, and recyclable.

Application

Powder Coating Line Widely used in metal surface products such as auto parts, furniture, wrought iron products, anti-theft doors, electric control cabinets, air conditioning racks, guardrails, radiators, motorcycles, electromechanical equipment, light industrial equipment, hardware and building materials, and various pipes in industry and agriculture. Anti-corrosion and insulation coating of small household appliances

Our Services

Hot Searches