- Product Details

- {{item.text}}

Quick Details

-

Power:

-

60kw

-

Weight:

-

5000kg

-

Dimension(L*W*H):

-

4.4x2.5x2.7m

-

Warranty:

-

12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material of Chamber:

-

SUS304 Stainless steel

-

Material of heating plates:

-

Aluminum

-

Quantity of cold trap:

-

Two cold traps with continuous defrot

-

Control system:

-

PLC& Indusrical computer

-

Material of trays:

-

Aluminum

-

High light:

-

Alternate double cold traps

-

Heating media:

-

Deionized water

-

Heating mode:

-

Radiation

-

Capacity:

-

500kg/batch

-

Certification:

-

ISO9001, CE

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Xinyang

-

Voltage:

-

380~480V 50/60Hz

-

Power:

-

60kw

-

Weight:

-

5000kg

-

Dimension(L*W*H):

-

4.4x2.5x2.7m

-

Warranty:

-

12 months

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material of Chamber:

-

SUS304 Stainless steel

-

Material of heating plates:

-

Aluminum

-

Quantity of cold trap:

-

Two cold traps with continuous defrot

-

Control system:

-

PLC& Indusrical computer

-

Material of trays:

-

Aluminum

-

High light:

-

Alternate double cold traps

-

Heating media:

-

Deionized water

-

Heating mode:

-

Radiation

-

Capacity:

-

500kg/batch

-

Certification:

-

ISO9001, CE

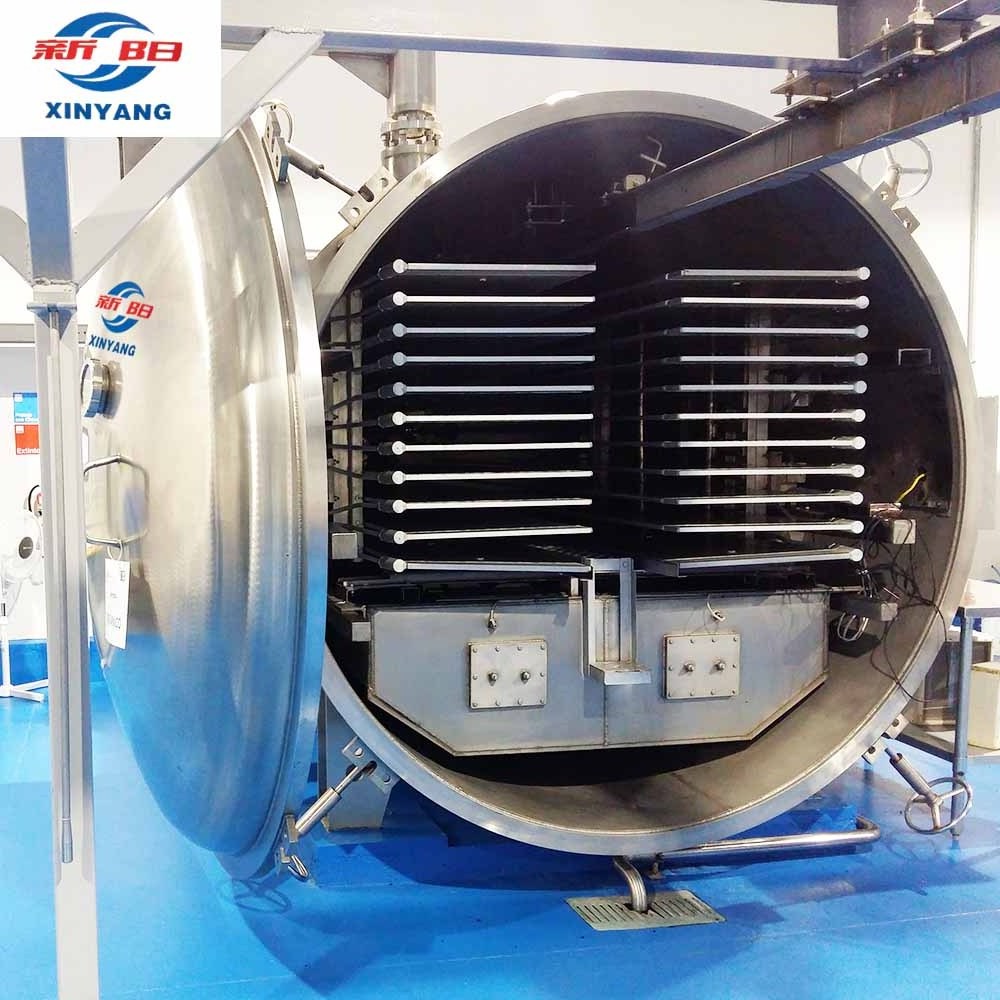

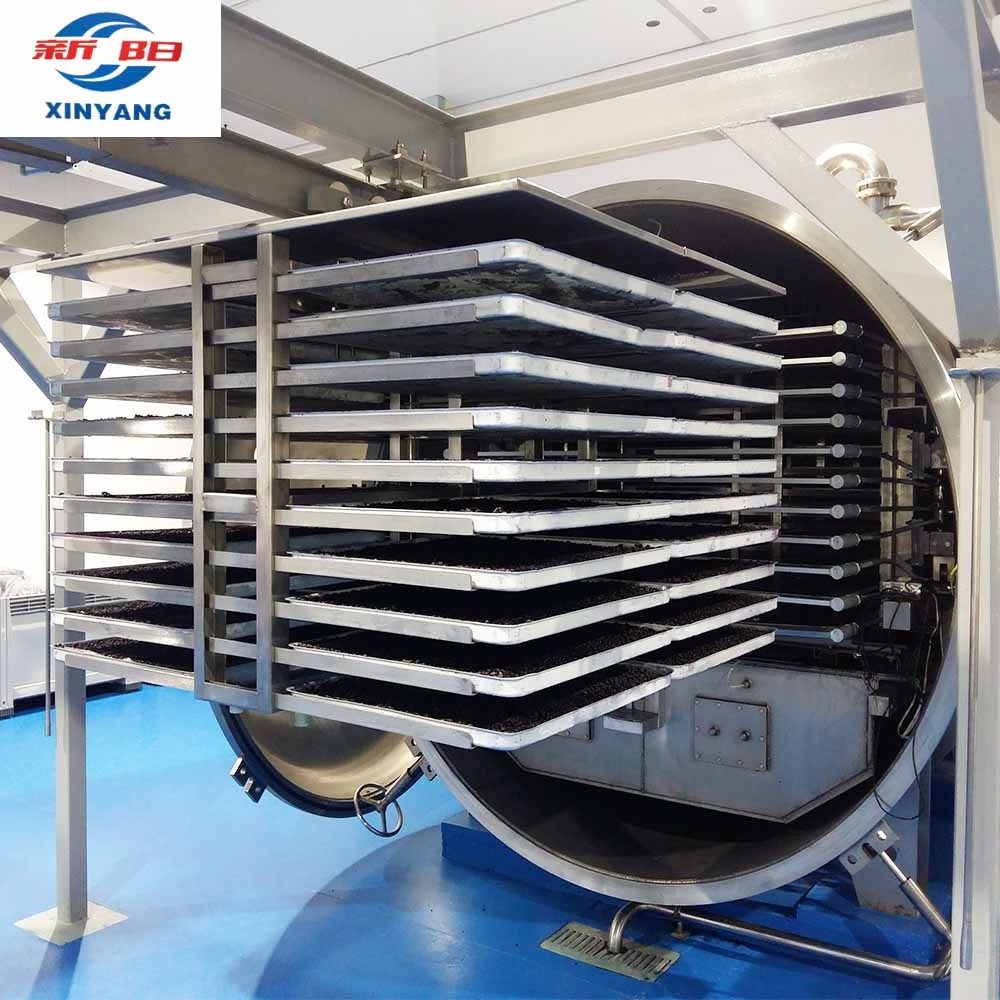

Working Princple of Freeze Drying Machine

Under vacuum condition, material is freeze dried via principle of sublimation. The moisture in the pre-frozen material is directly sublimed from solid state (ice) to gaseous state (vapor), without melting. Freeze dried products are formed as sponginess, no shrinkage, rehydration excellent, very little water containing. The freeze dried product in sealed packaging can be sto red and transported at room temperature for a long time.

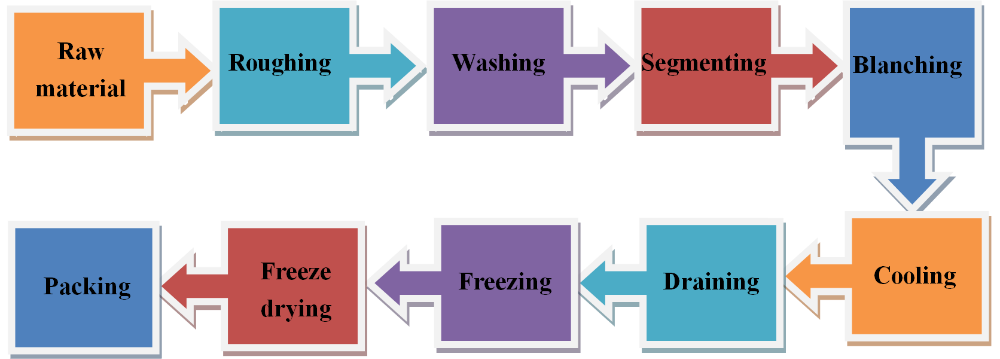

How to process the freeze dried food?

Technical parameter

Diameter of cabinet 2000 mm

Total length of cabinet 4400 mm

Maximum height (include hang support) 2700 mm

Gross weight of drying chamber 5000 kg

Material of drying chamber and cold trap 304

Heating medium Hot water

Pressure of Heating medium, (max.) 0.75MPa

Trays dimension 560*680*35 mm

Number of trays 80 pcs

Total surface of tray 30 m 2

Material of trays and heating plates Aluminum

Sublimation(average) 1.0 kg/m 2 h

Sublimation(max) 2.5kg/m 2 h

Circulation of Freon temperature -40 ℃

Temperature of Heating plate. Max 95 ℃

Vacuum range 50~133Pa

Refrigeration capacity (-40 ℃ evaporating) 60kw

Install power 80kw 380~480v 60Hz

Where to watch product video of Aerospace Xinyang?

"Freeze dryer" http://www.youtube.com/watch?v=bbvxYGB7XMg&feature=youtu.be

| Specification Model | LG30 | LG50 | LG75 | LG100 | LG125 | LG200 | |

| Heating Areas(m 2 ) | 30 | 50 | 75 | 100 | 125 | 200 | |

| Numbers of Vapor trap | Single | Double | Double | Double | Double | Double | Double |

| Trapping Capacity | >400kg/batch | >66kg/hr | >110kg/hr | >165kg/hr | >220kg/hr | >275kg/hr | >440kg/hr |

| Heating Medium | Water&electric | Water&Steam | Water&Steam | Water&Steam | Water&Steam | Water&Steam | Water&Steam |

| Heating Mode | Double side radiation | ||||||

| Temperature range of Heating plates | <95℃ | Normal Temp.~+130℃ | |||||

| Vacuum Pressure (Pa) | 20~133 | ||||||

| Need Refrigeration Capacity (t 0 =-40℃,t k =-35℃) (Kw) | 55 | 80 | 120 | 160 | 200 | 320 | |

| Consumption of Steam (kg/h) | None | 150 | 200 | 280 | 340 | 400 | 690 |

| Electric Power Supply (Kw) | 75 | 40 | 43 | 63 | 69 | 85 | 115 |

| Tray Numbers | 78 | 80 | 120 | 180 | 240 | 300 | 480 |

| Loading Raw Material | >390 | >400 | >600 | >900 | >1200 | >1500 |

>2400 |

Here to see small yield equipments!

Features

1. Much lower frying temperatures (approx. 90 to 120 ℃ in practical operation, depending on the product) to maintain flavours and colors.

2. Processing products with higher reducing sugar levels in comparison with normal atmospheric conditions.

3. Minimizing of health harmful thermal reaction products, such as acrylamide.

4. Texture can truly be influenced.

5. Evaporation rate will be faster.

6. Pressure as a new parameter of control next to retention time and temperature.

7. More gentle oil handling.

8. Lower steam pressure for frying oil heating systems required than in atmospheric fryers (approx. 8 bar).

9. No frying vapor emission.

Advantages

(Freeze drying equipment)

1. Efficiency of heating plates. The material of heating plates is aviation aluminum with anodized on the surface, over 100% heat release to the product by radiation, keeping heating uniformity completely.

2. Alternate vapor trap. Double vapor trap are installed under the heating plates in drying chamber. Trap 1 condenses water vapor to its maximum working cpacity, then trap 2 starts to condense. In the meantime,trap 1 begins to melt ice for another condensation cycle.

3. Continous de-icing. When the trap 2 begins to catch water vapor, the trap 1 begins to melt ice on the coil during the product being dried. After melting, the clean coil ready for another condensation cycle.

4. Automatic control system.

Advanced intelligent control system keeps the system running stably and reliably in a long time. Furthermore, simple operation can be much easier to handle.

(Freeze dried products)

1. Nutrition basically remains unchanged. Drying is operated in low temperature and vacuum conditions, so the nutrition is kept, particularly effective to heat sensitive materials.

2. Form basically remains unchanged. The water contained in food is drained directly from solid to gas, so the structure doesn’t change, and just forms space between ice crystals. .

3. Colour basically remains unchanged. As drying is operated in low temperature and vacuum conditions, the physical and chemical properties of food changed little. There is also little possibility of oxidation and enzyme, thus easily to keep original color.

4. Fragrance basically remains unchanged. Because the fragrant components in food largely exist in amorphous concentrated section in the process of freezing, the fragrance can be kept when ice crystals are gasified.

5. The quality of solids hardly losses. Because of the low rate of sublimating water vapor, the substances are basically in quiescent state, thus the loss of solids quality can be ignored.

1. We guarantee that the commodity hereof is made of the best materials and new brand with top workmanship, and in accordance with quality specification stipulated in product Contract and Appendix.

2. Guarantee period shall be within 12 months from the date of acceptance. During this period, if there are quality problems, we will provide solution by verbal or written communication. If the problem is unsolved, our engineers will repair for you on site as soon as possible. The maintenance is free when there are non-operation errors; otherwise it is for the buyer’s account.

Training plan: We will provide training for those who operate and maintain the freeze-drying machines. Trained by supplier of the equipment in the process of installation and debugging, people can operate and solve the basic mechnical problems independently . In addition, the persons who work in general engineering such as refrigeration, boiler, and transformer substation shall be undertaken by skilled workers.