- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

N/A

-

CrO Content (%):

-

N/A

-

SiC Content (%):

-

N/A

-

Place of Origin:

-

Guangxi, China

-

Model Number:

-

Corundum refractory castable

-

Brand Name:

-

KAITE

Quick Details

-

SiO2 Content (%):

-

N/A

-

Al2O3 Content (%):

-

25-90%

-

MgO Content (%):

-

N/A

-

CaO Content (%):

-

N/A

-

CrO Content (%):

-

N/A

-

SiC Content (%):

-

N/A

-

Place of Origin:

-

Guangxi, China

-

Model Number:

-

Corundum refractory castable

-

Brand Name:

-

KAITE

Refractory castable material is a granular and powdery material made of refractory material, and adding a certain amount of binder and water together. It has a high mobility, suitable for the construction of the pouring method, without heating and hardening of monolithic refractory.

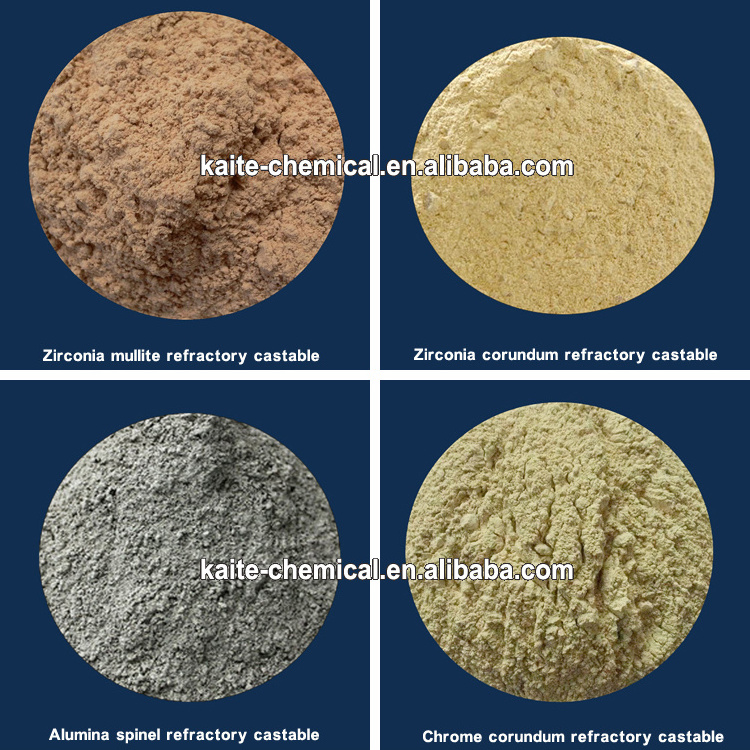

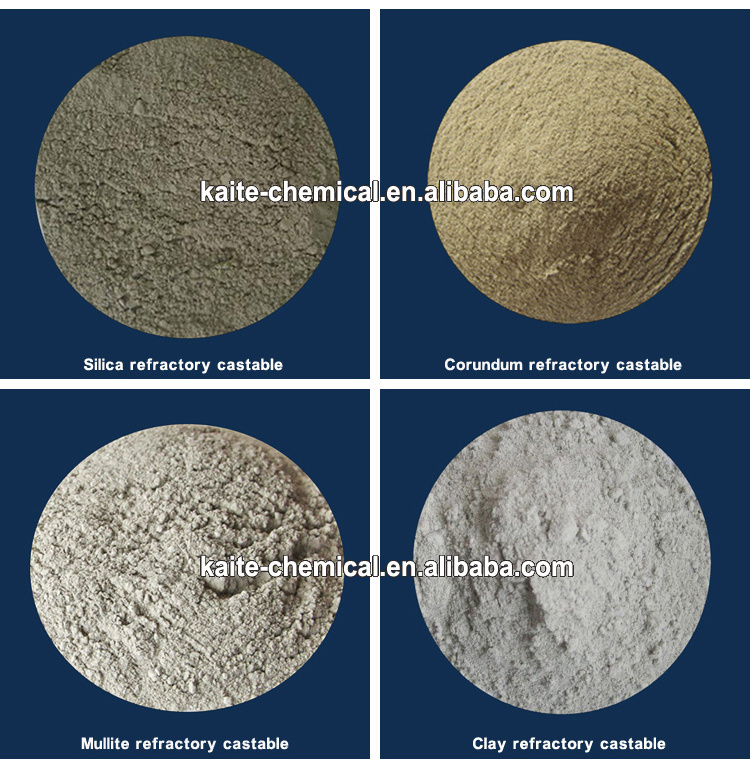

Product Type

1. Clay refractory castable.

2. High alumina refractory castable.

3. Silica refractory castable.

4. Corundum refractory castable.

5. Mullite refractory castable.

6. Chrome corundum refractory castable.

7. Zirconia corundum refractory castable.

8. Zirconia mullite refractory castable.

9. Alumina spinel refractory castable .

10.Magnesite alumina spinel refractory castable.

Refractory castable material is mainly used in the metallurgical industry furnace, and also widely used in petroleum, chemical, building materials, electric power and mechanical industrial furnace and thermal equipment.

|

Low Cement Refractory Castable |

||||||

|

Item |

Index |

|||||

|

Al 2 O 3 content, % ≥ |

50 |

60 |

70 |

80 |

90 |

|

|

CaO content, % ≤ |

2.5 |

2.2 |

2.0 |

2.0 |

1.8 |

|

|

Bulk density, g/cm 3 ≥ |

2.35 |

2.45 |

2.50 |

2.60 |

2.95 |

|

|

Cold crushing Strength, Mpa ≥ |

110 °C ×24h |

20 |

25 |

30 |

30 |

40 |

|

1000 °C ×3h |

45 |

50 |

55 |

55 |

65 |

|

|

1400 °C ×3h |

60 |

65 |

70 |

70 |

80 |

|

|

Linear on reheating, % |

1400 °C ×3h |

±0.5 |

±0.4 |

±0.4 |

±0.3 |

±0.4 |

|

Max. service temperature, °C |

1400 |

1450 |

1500 |

1550 |

1650 |

|

|

Water consumption, % |

6 - 7.5 |

6 - 7.5 |

6 -7.5 |

6 -6.5 |

6 - 6.5 |

|

|

Clay Bonded Refractory Castable |

||||||

|

Item |

Index |

|||||

|

Al 2 O 3 content, % ≥ |

45 |

60 |

70 |

60 |

65 |

|

|

Bulk density, g/cm 3 ≥ |

2.30 |

2.35 |

2.50 |

2.38 |

2.40 |

|

|

Cold crushing Strength, Mpa ≥ |

110 °C ×24h |

9 |

10 |

11 |

13 |

15 |

|

1000 °C ×3h |

35 |

40 |

45 |

45 |

50 |

|

|

1400 °C ×3h |

40 |

45 |

50 |

50 |

50 |

|

|

Linear on reheating, % |

1400 °C ×3h |

±0.6 |

±0.5 |

±0.4 |

±0.5 |

±0.4 |

|

Max. service temperature, °C |

1400 |

1450 |

1500 |

1450 |

1500 |

|

|

Water consumption, % |

6 - 8 |

6 - 8 |

6 -8 |

6 -8 |

6 - 8 |

|