- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Dimension(L*W*H):

-

L2020*W870*H1590(MM)

-

Weight:

-

260 KG

-

Power:

-

2.2KW

-

Conveying roller width:

-

300MM

-

Conveyor line height off the ground:

-

750MM±50MM

-

range of speed:

-

4000-8000B/H

Quick Details

-

Application:

-

Food

-

Packaging Type:

-

Bottles

-

Packaging Material:

-

Plastic, Metal, Glass, Wood

-

Voltage:

-

220V/50HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

LC

-

Dimension(L*W*H):

-

L2020*W870*H1590(MM)

-

Weight:

-

260 KG

-

Power:

-

2.2KW

-

Conveying roller width:

-

300MM

-

Conveyor line height off the ground:

-

750MM±50MM

-

range of speed:

-

4000-8000B/H

Product Description

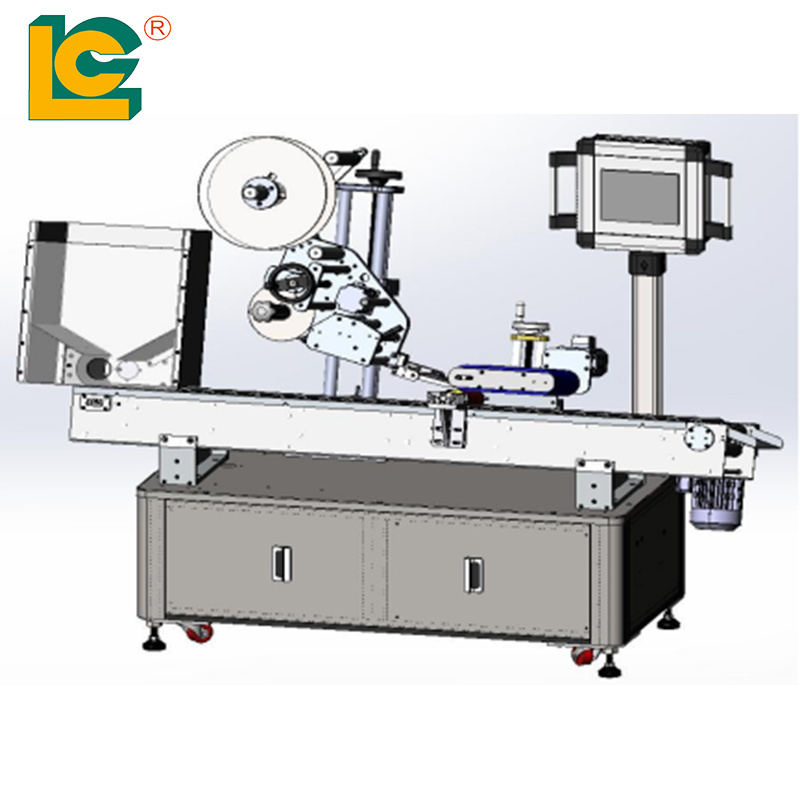

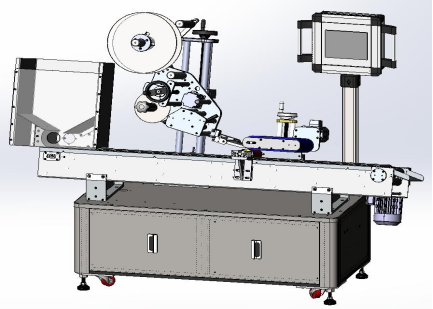

1) Humanized touch screen: simple and intuitive operation, complete functions, with rich online help functions;

2) Horizontal transmission and horizontal labeling are adopted to increase stability and improve labeling efficiency;

3) The coding machine or inkjet machine can be selected to the labeling head, which can print the production date, batch number and spray bar code on the label;

4) Equipped with automatic feeder, with the whole machine to use, the highest labeling speed of up to 400 bottles/min;

5) Labeling has the function of counting and parameter storage (20 groups of labeling parameters can be preset, no need to reset when changing the labeling product);

6) Inclined design, the object is automatically positioned;

7) Optional loading dial, increase bin design, fast and convenient loading;

8) Can cooperate with automatic cutting system, save a lot of manpower and material resources;

9) Can be used in a single machine, can also meet the line use.

Specification

|

Machine Name

|

Straight automatic self-adhesive horizontal round bottle labeling machine

|

|

|

||

|

Machine Model

|

LC-295W

|

|

|

||

|

Power

|

2.2KW

|

|

|

||

|

Machine Voltage

|

220V/50HZ

|

|

|

||

|

Number of stations

|

1

|

|

|

||

|

Fit bottle

|

Suitable for circular or semi-circular labeling of unstable cylindrical objects (different products, need to add replacement parts, additional cost)

|

|

|

||

|

Conveying roller width

|

300MM (suitable for 100-350MM height or 40MM-70MM diameter product labeling) can be made according to the width of the labeled product

|

|

|

||

|

Conveyor line height off the ground

|

750MM±50MM(Height can be made according to demand)

|

|

|

||

|

Range of speed

|

1 ~ 40m/min 4000-8000B/H (different sizes of products, different speeds)

|

|

|

||

|

External Dimension

|

L2020*W870*H1590(MM)

|

|

|

||

|

Weight

|

260KG

|

|

|

||

|

Label loss rate

|

≤0.5‰

|

|

|

||

|

Labeling deviation and pass rate

|

≤±1MM

|

99.7%

|

Note: Label, bottle body, and handling errors are not included.

|

||

|

Labeling up and down deviation and pass rate

|

≤±0.5MM

|

99.7%

|

Note: Label, bottle body, and handling errors are not included.

|

||

|

Applicable label size

|

The maximum label width is less than 190MM. If the label width exceeds this range, you need to customize and add a high header.

Inner diameter of roll: 76.2MM outer diameter of roll ≤350MM Label requirements: not too thin, difficult to peel off, easy to wrinkle Note: If you exceed the above range, you need to inform in advance to determine whether the machine can be used simultaneously. |

|

|

||

Details of the machine

PLC(Programmable controller) using Germany Siemens

Large size color touch screen, integrated machine parameters, production conditions, fault alarm and other related information, English and Chinese operation interface, switching is extremely convenient, you can also design small language operation interface on demand.

Outgoing header

1) The latest design concept, the use of three-bar adjustment mechanism, make full use of the stability of the triangle, the whole machine is solid and durable;

2) Surface hardening treatment, new optimization of marking envelope Angle, ensure smooth marking, avoid up and down marking phenomenon;

Optimize the step of replacing the label, make the operation more simple, multidimensional adjustment mechanism, fast marking speed and good stability

Delivery System

1) Taiwan imported AC motor 370W, Danfoss frequency control;

2) The conveyor line adopts POM roller conveyor to better adapt to standing unstable products.

Belt hoisting mechanism:

1) Blue cloth roll belt structure, speed control motor;

2) Four-dimensional Angle adjustment to better solve the problem of taper round bottle labeling;

3) The installation of soft material automatic filling auxiliary labeling mechanism can better reflect the labeling effect and improve production capacity.

LC-295W Labeling machine Performance features:

A: The mainframe uses two cutting-edge technologies from our company:

1) Double press roller feeding, which is conducive to improving the labeling accuracy because the label is rolled by the active press roller before labeling, which is conducive to eliminating label wrinkles, improving the labeling quality, and exhausting the last label;

2) Two-stage swing bar spring type marking clutch, additional belt brake, to achieve high-speed constant tension marking.

|

NO.

|

NAME

|

Manufacturer

|

||

|

1

|

Touch screen

|

Siemens

|

||

|

2

|

servomotor

|

Yaskawa

|

||

|

3

|

Servo driver

|

Yaskawa

|

||

|

4

|

Transmission line inverter FC51

|

Danfoss, Denmark

|

||

|

5

|

Bottle mechanism inverter FC51

|

Danfoss, Denmark

|

||

|

6

|

PLC

|

Siemens

|

||

|

7

|

Tag eye

|

SICK in Germany

|

||

|

8

|

Electric eye for measuring objects

|

SICK in Germany

|

||

|

9

|

Conveyor motor 370W

|

Taiwan Wanxin

|

||

|

10

|

Bottle rolling mechanism motor

|

Taiwan Jingyan

|

||

|

11

|

Switching power supply

|

Taiwan Ming Wei

|

||

|

12

|

Ac contactor

|

CHNT

|

||

|

13

|

Universal change-over switch

|

Schneider

|

||

|

14

|

Scram switch

|

Schneider

|

||

|

15

|

Circuit breaker

|

CHNT

|

||

|

16

|

Soft bottle automatic filling auxiliary labeling mechanism motor

|

Taiwan Jingyan

|

||

|

The whole machine is composed of high-grade 304 stainless steel and aluminum alloy by anodizing treatment

|

|

|

||

Hot Searches