- Product Details

- {{item.text}}

Quick Details

-

Gasification efficiency:

-

>72%

-

Exhauster Power:

-

210W

-

Exhauster Pressure:

-

1200Pa

-

Exhauster Electrical Source:

-

24V DC

-

Cooling Fan Power:

-

90W

-

Cooling Fan Electrical Source:

-

12V DC

Quick Details

-

Place of Origin:

-

Shandong, China

-

Gas output(L/h):

-

30-1500m3/h

-

gas caloric value:

-

4600-5200KJ/m3

-

Gasification efficiency:

-

>72%

-

Exhauster Power:

-

210W

-

Exhauster Pressure:

-

1200Pa

-

Exhauster Electrical Source:

-

24V DC

-

Cooling Fan Power:

-

90W

-

Cooling Fan Electrical Source:

-

12V DC

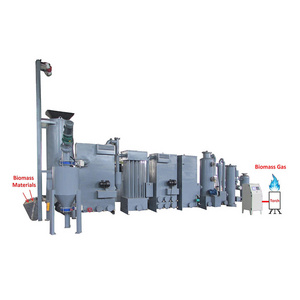

LSG—30A appliance down draught syngas producer is wood wood chip burner that uses crop straw and other agricultural wastes to make straw gases . It is a great product that utilizes the syngas gasification pyrogenation technology to produce environmentally friendly gases using common biological materials such as straw. It serves as a solution to environment pollution caused by destroying straw on fire and save trees by replacing them by straws. Thus, it protects environment, saves energy sources and improves the life quality of farmers.

The technology of down draught syngas gasification is a technology that converts biological materials such as straw into energy by a high-pressure exhaust fan in a high temperature state. Straw is mainly composed of carbon, hydrogen, oxygen and ash. When these elements meet in a controlled high temperature state, they combine together to be carbon monoxide, hydrogen gas, and methane. These are all burnable gas. The process in which biological materials converts into burnable gas is named gasifying process.

The principle of gasifying process: biological materials enter combustor, and undergo heat drying. As the temperature increases, the volatile is separated out and split. After splitting, the gas and carbon meet supplied air in the oxidation area and combustion takes place. The combustion results in CO ,CO2 and vapor. The heat from combustion is utilized to maintain dryness, splitting reaction and endothermic reaction of the underneath reversion area. The gas resulted from the combustion goes through the reversion area and reacts with carbon layer(C+CO2=2CO,C+HO2=H2+CO), which produces burnable gas consisting of CO,H2,CH4,CmHn. The burnable gases are separated from impurities such as tar, and are output from the bottom ready for use. The ash is discharged from the bottom of the wood wood chip burner.

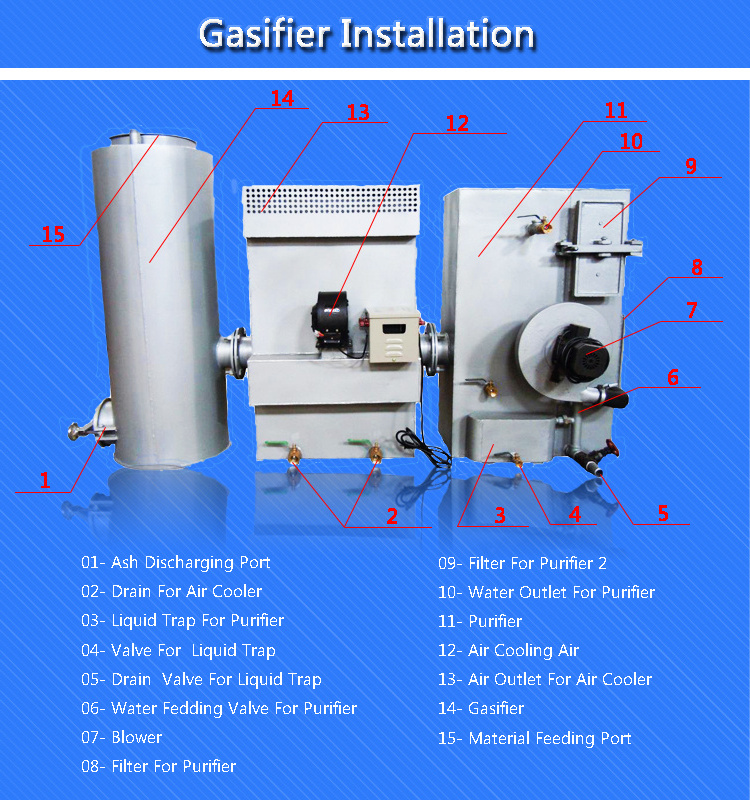

- The wood wood chip burner can be installed inside or outside of a residence. If installed inside, it should not be in bedroom or rooms connecting to the bedroom, so that CO poisoning is prevented. The place where the wood wood chip burner is installed must have good ventilation.

- The place where the wood wood chip burner is installed should have 220V/400V power outlet(s) for exhauster.

- A special rubber hose, steel hose or PE hose can be used to connect the Combustion equipment the gasification stove. The connection should be level to prevent water accumulation in the hose that can block the gas passageway.

- Furnace combustion equipment and gas connection installed between the emission pipes, install the valve

- The room installed with Combustion equipment should have a powerful ventilator.

- The ventilation pipes of the the wood wood chip burner should be connected to the air outside of the residence.

- The wood wood chip burner has a circulating water cooling system. Be sure to connect the upper and lower valves behind the purifier to the water tank securely.

- Purifier plus behind pipes on overflow, the manifold is connected, To open the valve of the manifold, the device when not emit the sewage collected.

- Smash dry straw into pieces of about 2 cm in length. The moisture of straw should be under 20%.

- Open the filter chamber of the purifier, and fill it with filtration medium (active carbon or maize core etc). Close the door tightly and examine airproof of the door.

- Fill the lower sealed water tank by using the input water hose behind the purifier, Open water traps, valves, valve water, stop adding water.

- Fill the circulating water tank by using the upper input water hose on the left side of the purifie.

- Check the airproof of the ash-discharge door. Examine the airproof of valves.

- Check the airproof of the connection between wood wood chip burner and the Combustion equipment.

- Turn on the powerful ventilator.

- Turn off the gas valve of the Combustion equipment and turn on the valve of the vent-pipe.

- Plug in the high-pressure exhauster. Put straw into combustor of the wood wood chip burner until it is half full as fire starter. Ignite the straw in the combustor, and add more straw until it is full.

- Straw lit for 2-5 minutes, to open the gas equipment valves, the start gas equipment, gas equipment normal operation, close the exhaust pipe valve

- Control the gas producing rate of the wood wood chip burner by using the output valve of the purifier.

- On discharging the ash, keep half stove of ash, On the next use, turn on the exhauster and place fire starter into the combustor. After the fire starter starts burning over the ash, fill the combustor with straw. The gases are good to use in 2 minutes.

- Remove the ash regularly. Generally clean it once every day. Be sure to clean inside wall of the stove, and around the discharge door trims.

- Clean the cushion of the ash-discharge door. Replace it if it is worn out.

- Clean regularly the waste water and tar in filter. Clean it once every 10-15 days

- Check regularly whether there is water accumulation in the vent pipes, drain it if there is.

L ocated in Weifang City, Shandong Province, Weifang Ronsun Power Machinery Co., Ltd. is the biggest power machinery manufactory in Weifang City. Ronsun Power has more than 10 year's experience in manufacturing the biomass wholesale generators set.

E verytime foucus Ronsun Power on improving its technology on wood chip burners and generators, such as, ignition controller, gas mixing and pressure adjusting system etc.. This kind of system has many advantages, such as efficient, easy to start and maintain, anti-knock, entire intelligent opertion etc. Besides, Ronsun Power has established a long-term strategic partnership with some of the world's famous companies, such as CUMMINS, PERKINS, MTU, DEUTZ, WEICHAI, STAMFORD, LEROY SOMER, MARATHON etc.

R onsun Power company has a big range of its products, which covers nearly all kinds of wood chip burners and generator sets, such as bio gas Genrator Set, LPG Generator Set, Biowholesale generators Set, Synwholesale generators Set, Biomass wholesale generators Set, etc. And the power range differs from 10KW to 1000KW. The Ronsun Power regards the quality of the products as the most important thing. The quality of Ronsun's products and service have met the requirement of clients at home and abroad. Ronsun has many biomass generator running in food service, animal husbandry, aquaculture and oil interests industries. And its products are exporeted to Australia, Italy, Czech, Slovenia, France and dozens of countries in Southest Asia, South America and Africa.