- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongji

-

Voltage:

-

Clients local standard

-

Dimension(L*W*H):

-

depond on model

-

Weight (KG):

-

5000 kg

-

Product name:

-

Coal Belt Conveyor Machine B1200

-

Belt material:

-

Carbon steel, Carbon steel, Steel

-

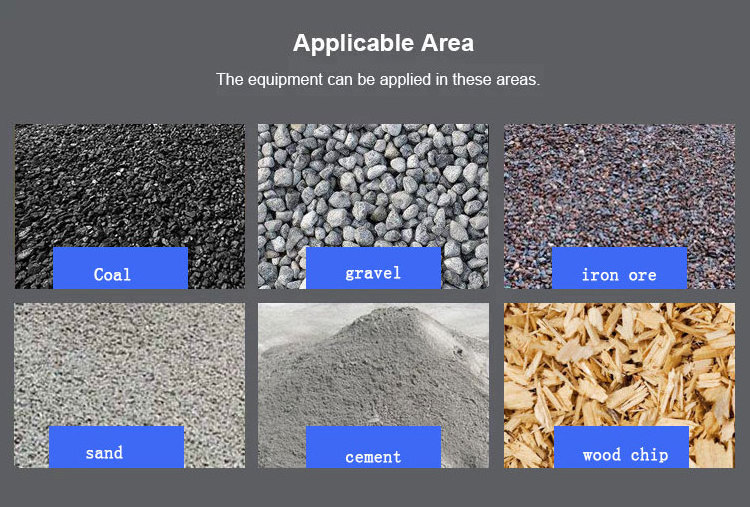

Application:

-

Sand Coal and mining

-

Color:

-

Customers' Request

-

Installation:

-

Engineer's Guide

-

After-sales Service:

-

Problems Within 48 Hours

-

price:

-

negotiation

-

Feature:

-

High Efficiency

-

Certification:

-

CE,ISO,EAC

Quick Details

-

Power:

-

1.5-38

-

Warranty:

-

2 years

-

Width or Diameter:

-

40mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongji

-

Voltage:

-

Clients local standard

-

Dimension(L*W*H):

-

depond on model

-

Weight (KG):

-

5000 kg

-

Product name:

-

Coal Belt Conveyor Machine B1200

-

Belt material:

-

Carbon steel, Carbon steel, Steel

-

Application:

-

Sand Coal and mining

-

Color:

-

Customers' Request

-

Installation:

-

Engineer's Guide

-

After-sales Service:

-

Problems Within 48 Hours

-

price:

-

negotiation

-

Feature:

-

High Efficiency

-

Certification:

-

CE,ISO,EAC

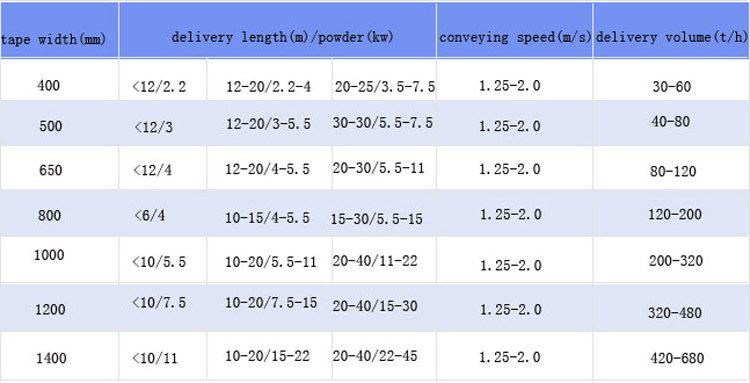

Coal Belt Conveyor Machine B1200

Belt Conveyor is the essential and economical transferring set in the uninterrupted production line.it consists of standard parts ,and easy maintenance so widely used in mining ,metallurgy and chemical industry to transfer stone materials or packaged materials, compared with other transportation equipment (such as locomotive), it has the advantages of long conveying distance, large capacity, continuous transportation and reliable operation, easy to achieve automation and centralized control, Belt Conveyor has become the key equipment in mining process.

Working Principle of Belt Conveyor:

The convery belt is mainly composed by the expansion cylinder on both ends and the closed belts tightly knotted on them. The revolving cylinder of the conveyor belt is called driving cylinder, and the other cylinder which is mainly used for changing the moving direction of the belt is called redirection cylinder. The driving cylinder drive the device through the electromotor on the reducer, and the belt pulls relying on the friction of the driving cylinder and the conveyor belt. The driving cylinder is usually installed on the materials discharging side for purpose of increasing the pulling force. The materials are fed from the feeding end, and then they will fall on the revolving conveyor belt, and relying on the friction force of the belt conveyor, the conveying materials are driven to the material discharging end for discharging.

After-Sales Service

1) After acceptance of the equipment, we will draft the construction program and detailed process, and complete the export process.

2) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

3) Spare parts and wearing parts will be offered with production cost in 10 years.

After-Sales Service

1) After acceptance of the equipment, we will draft the construction program and detailed process, and complete the export process.

2) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

3) Spare parts and wearing parts will be offered with production cost in 10 years.

Certifications