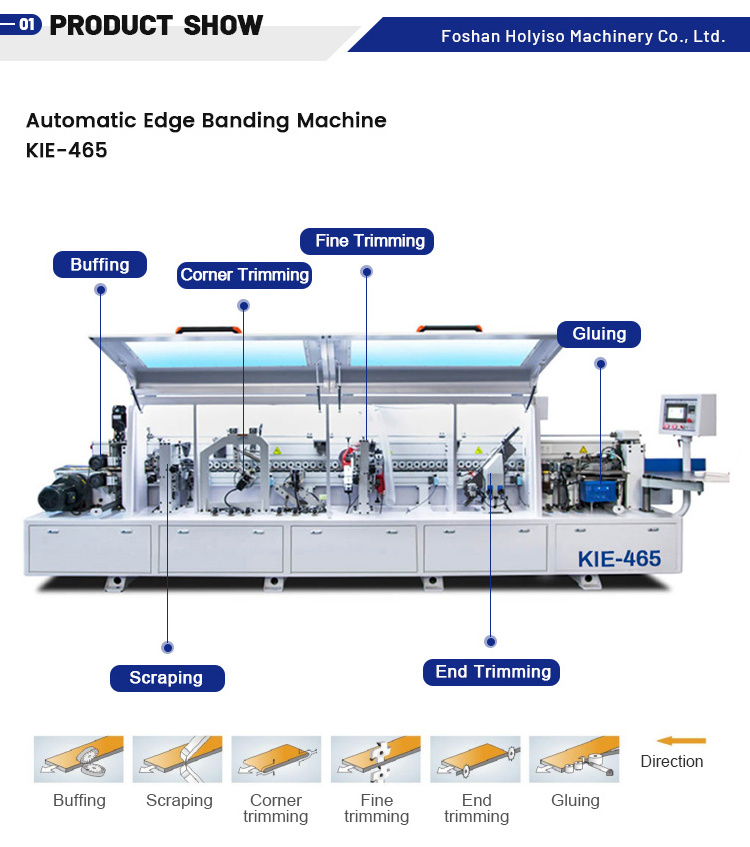

2.The machine can be customized. Auto cleaning, high precision, high efficiency.

3.Aluminum alloy beam is a relatively advanced method,precisione and straightness are far superior to cast iron.Stability and controlled ability are the most important,factors for an equipment to be part of production line.

3.Aluminum alloy beam is a relatively advanced method,precisione and straightness are far superior to cast iron.Stability and controlled ability are the most important,factors for an equipment to be part of production line.

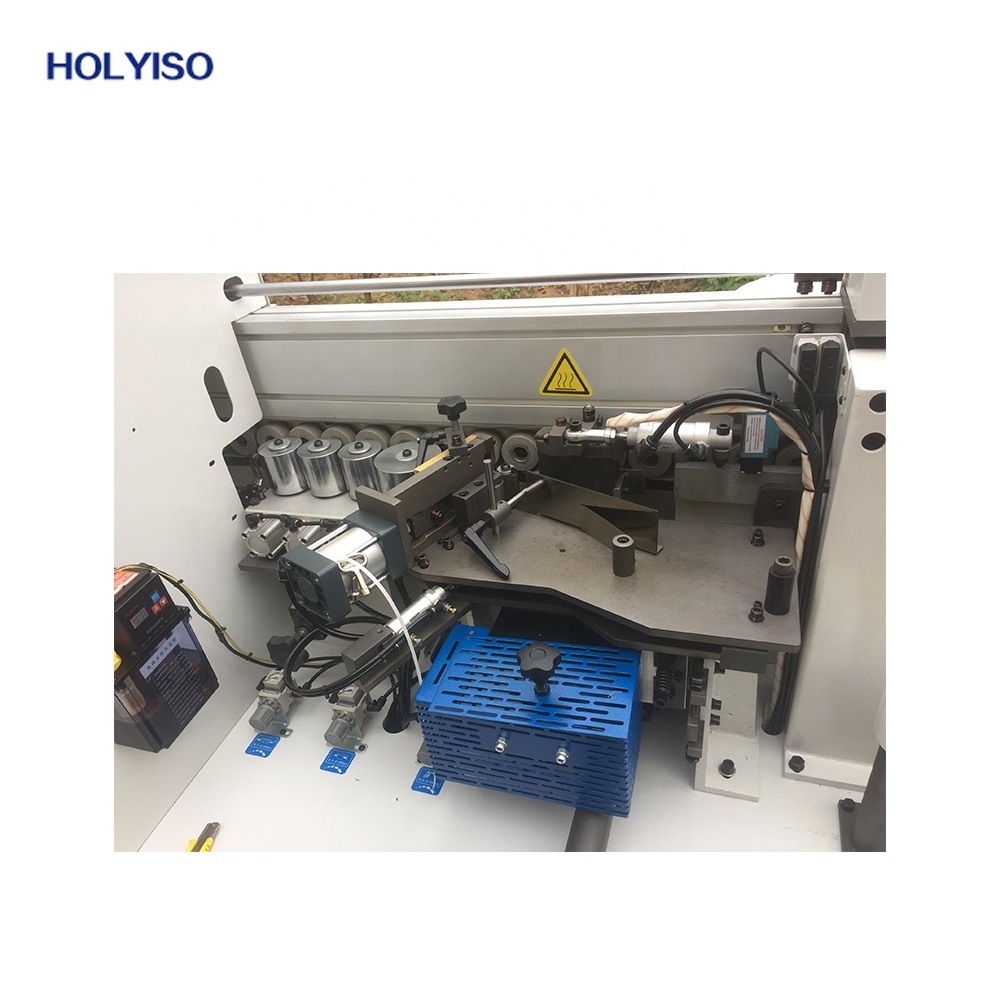

4.Automatic and precise gluing procedure as well integrated double finishing side within one workflow .The end cutting can be done at the rear side of the machine.

Application:

The machine is suitable for the following boards: MDF, block board, solid wood board, particleboard, polymer door plates, plywood, pvc board, etc. Straight line edging and trimming.

Application:

The machine is suitable for the following boards: MDF, block board, solid wood board, particleboard, polymer door plates, plywood, pvc board, etc. Straight line edging and trimming.

It

can be used for whole house customization, panel furniture, kitchen dining room, oddice cabinet table,etc