- Product Details

- {{item.text}}

Quick Details

-

Design Printing:

-

No printing

-

Material:

-

acrylic foam

-

Feature:

-

Waterproof

-

Use:

-

MASKING

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Naikos

-

Model Number:

-

NKS Series

-

Thickness:

-

Customizable, 1.00mm±50μm

-

Color:

-

grey,white,clear

-

Heat Resistance:

-

-20C to 120C

-

Carrier:

-

Acrylic Foam

-

Standard Roll Width:

-

800mm

-

Standard Roll Length:

-

33m

-

Tensile strength:

-

≥7,000

-

Peel Adhesion:

-

≥4,000gf/25mm

-

Holding Power:

-

>24Hr

Quick Details

-

Adhesive:

-

Acrylic

-

Adhesive Side:

-

Double Sided

-

Adhesive Type:

-

Pressure Sensitive

-

Design Printing:

-

No printing

-

Material:

-

acrylic foam

-

Feature:

-

Waterproof

-

Use:

-

MASKING

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Naikos

-

Model Number:

-

NKS Series

-

Thickness:

-

Customizable, 1.00mm±50μm

-

Color:

-

grey,white,clear

-

Heat Resistance:

-

-20C to 120C

-

Carrier:

-

Acrylic Foam

-

Standard Roll Width:

-

800mm

-

Standard Roll Length:

-

33m

-

Tensile strength:

-

≥7,000

-

Peel Adhesion:

-

≥4,000gf/25mm

-

Holding Power:

-

>24Hr

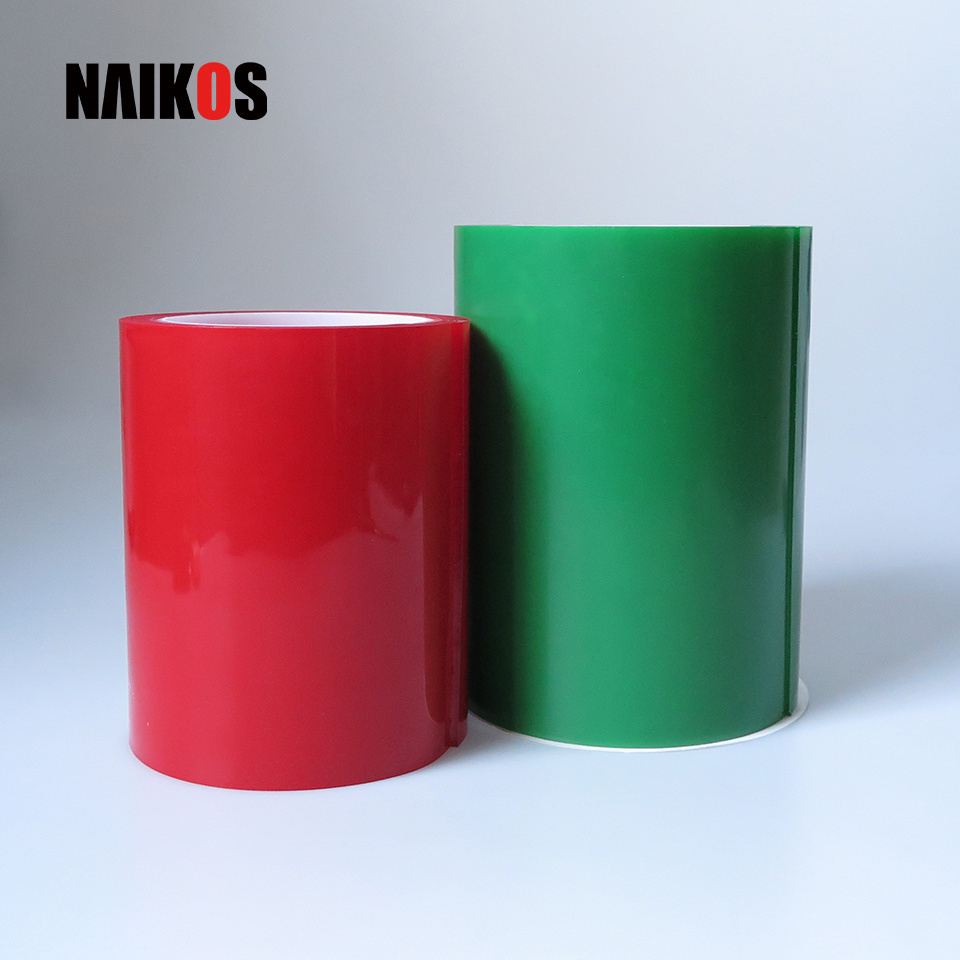

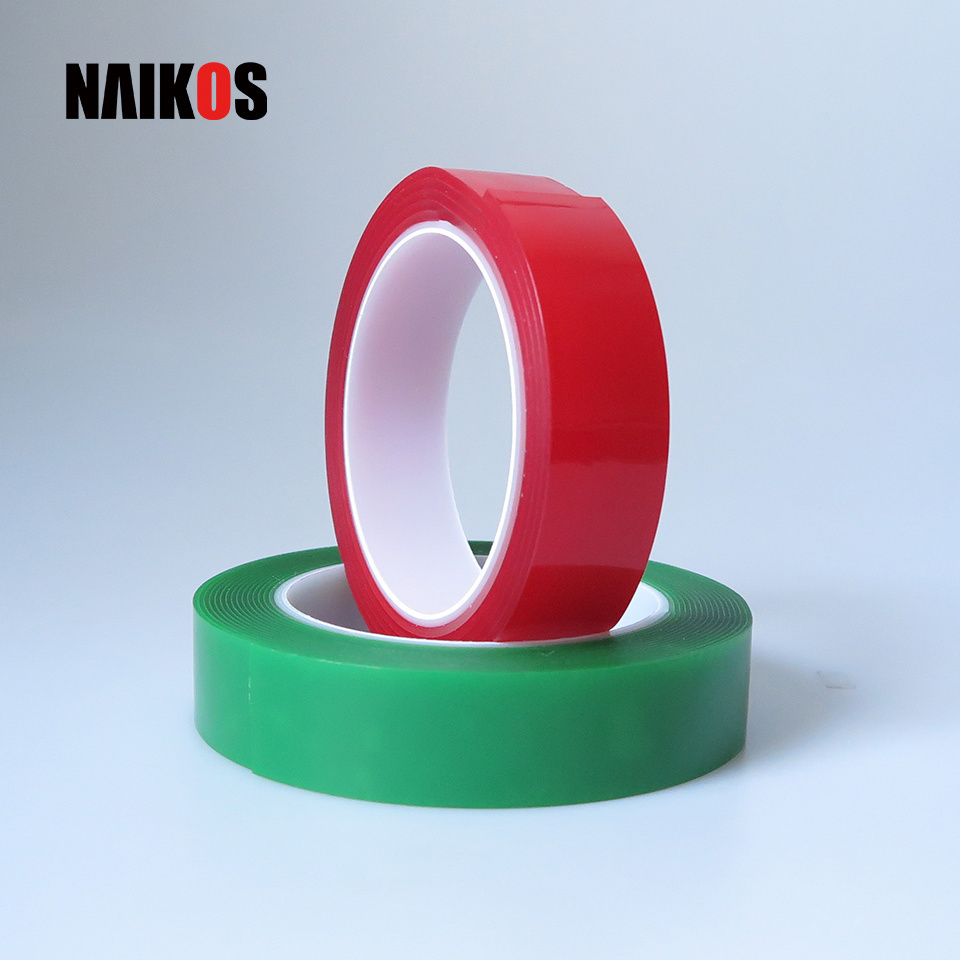

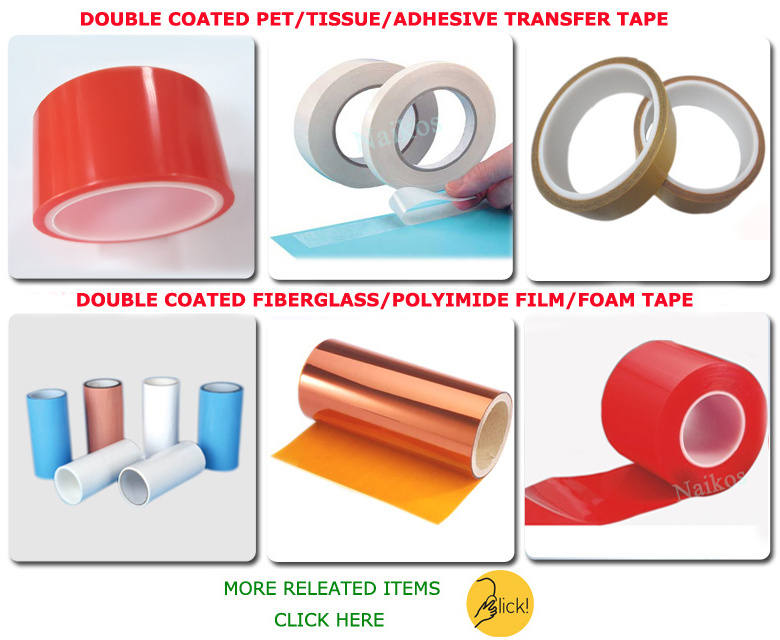

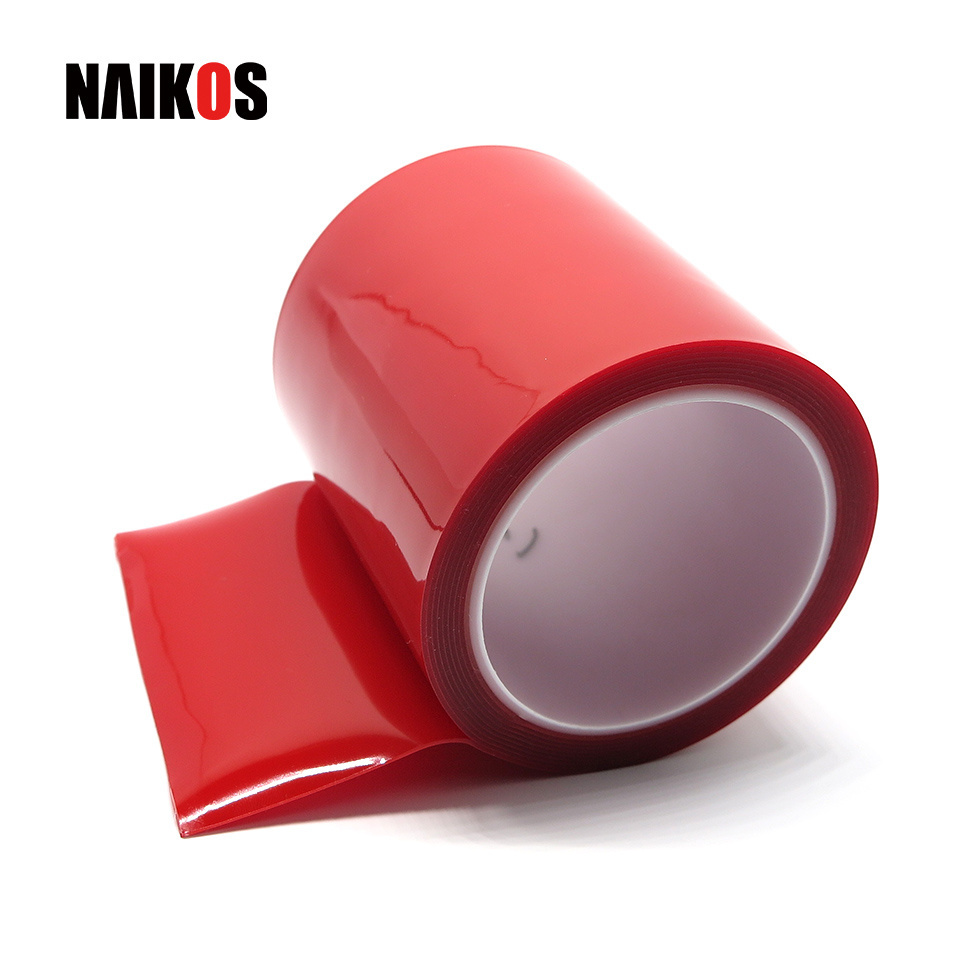

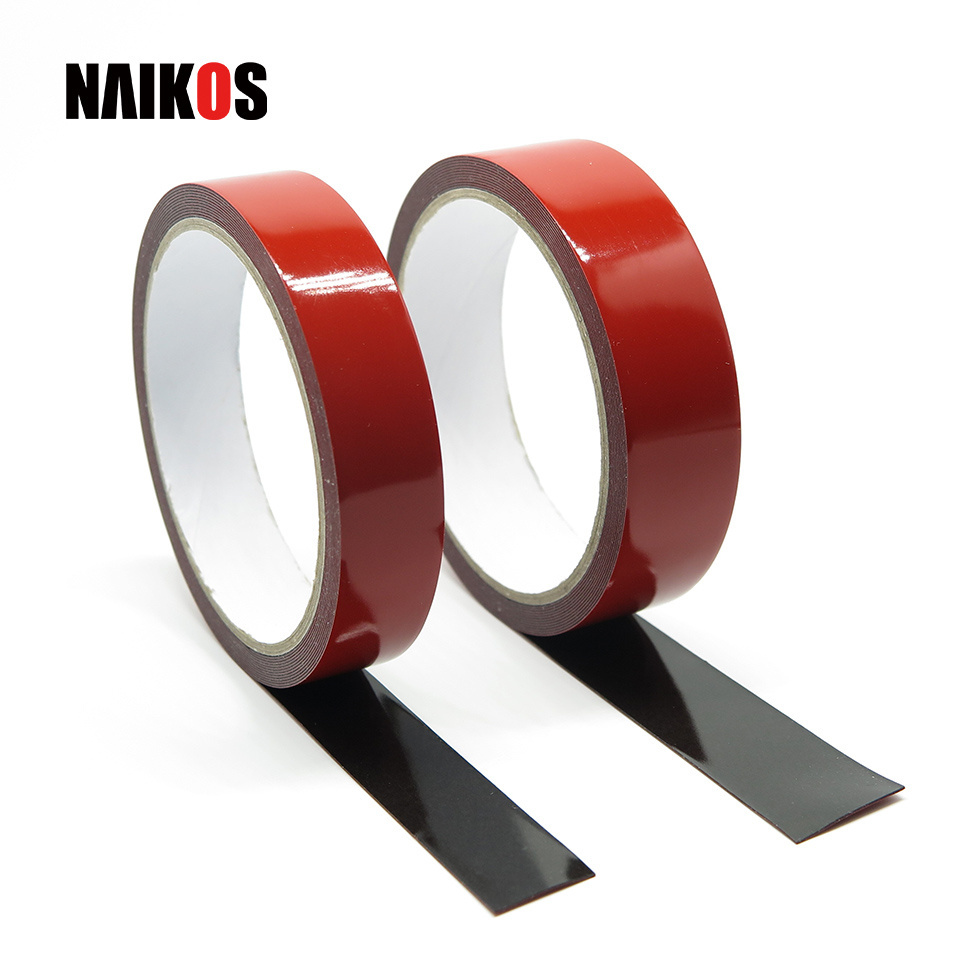

Heat Resistant Waterproof Adhesive Double Sided Acrylic Foam Tape

Heat Resistant Waterproof Adhesive Double Sided Acrylic Foam Tape

1.Base material: acrylic foam

2.Color: gray, white, transparent

3.For metal, glass, window,door,furniture, automotive, industry bonding

4.very high bonding

FEATURES FOR FOAM TAPE

1.High strength bonding tape can be used to replae screws, rivet and weld

2.Instant bonding

3.Shock Absorption

4.Stress distribution

5.Expansion and construction

6.Waterproof and permanent bonding

7.Flexible and conform to irregular and rigid surface

8.Clean surface without using of rivet

9.Flexible, easy for die cutting

APPLICATION

1.Glass wall assembly, very strong for sealing, dustproof

2.Construction industry, sealing, waterproof and bonding

3.Electronic products

4.Automotive industry, decorative strip,nameplate, furniture and label

5.Solar Panel

CONSTRUCTION

| acrylic PSA | ||

|

acrylic foam |

|

|

|

acrylic PSA |

||

|

red PE film |

PHYSICAL PROPERTIES

|

Item |

Unit |

Value |

Test Method |

|

Carrier |

|

Acrylic Foam |

|

|

Adhesive |

|

Acrylic |

|

|

Color |

|

Clear |

|

|

Thickness |

mm |

1.00±50μm |

ASTM-1000 |

|

Standard Roll Width |

mm |

800 |

|

|

Standard Roll Length |

m |

33 |

|

|

Tensile Strength |

Gf/cm² |

≥7,000 |

(T-Block) To Aluminum |

|

Peel Adhesion |

gf/25mm |

≥4,000 |

To Stainless Steel Room Temperature 180°Peel |

|

Holding Power

|

Hr |

>24 |

To Stainless Steel 80℃ Temperature 1000g Static Load |

Note: The above technical information and data should be considered representative or typical only and should not be used for specification purposes.

SHELF LIFE

Product shelf life is 2 years from date of manufacture when stored at room temperature conditions (72°F [22°C] and 50% RH) in the products original packaging.

AVAILABLE SIZES

width: Maximum width 33.00inches (840mm). (can be Customized)

length: 33m (can be customized).

custom Sizes: If you need customized sizes or die cut parts please feel free to contact NKS sales representative.

APPLICATION GUIDELINES

1.) Substrate surfaces should be clean and dry prior to tape application. Isopropyl alcohol (isopropanol) applied with a lint free wipe or swab should be adequate for removing surface contamination such as dust or finger prints. Do not use “denatured alcohol” or glass cleaners which often contain oily components. Allow the surface to dry for several minutes before applying the tape. More aggressive solvents (such as acetone, methyl ethyl ketene (MEK) or toluene) may be required to remove heavier contamination (grease, machine oils, solder flux, etc.) but should be followed by a final isopropanol wipe as described above.

Note: Be sure to read and follow the manufacturers’ precautions and directions when using primers and solvents.

2.) Apply the tape to one substrate at a modest angle with the use of a squeegee, rubber roller or finger pressure to help reduce the potential for air entrapment under the tape during its application. The liner can be removed after positioning the tape onto the first substrate.

3.) Assemble the part by applying compression to the substrates to ensure a good wetting of the substrate surfaces with the tape. Proper application of pressure (amount of pressure, time applied, temperature applied) will depend upon design of the parts. Rigid substrates are more difficult to bond without air entrapment as most rigid parts are not flat. Use of a thicker tape may result in increased wetting of rigid substrates. Flexible substrates can be bonded to rigid or flexible parts with much less concern about air entrapment because one of the flexible substrates can conform to the other substrates.