- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanjing Sumino

-

Voltage:

-

220V or 380V or customization

-

Dimension(L*W*H):

-

customization

-

Power (kW):

-

150

-

Weight:

-

2500 KG

-

mechanical Specifications:

-

800-2300mm

-

speed of coating film:

-

100-150

-

thickness of coating film:

-

0.012~0.1mm

-

Effective screw L/D:

-

30:1

-

main unwinding diameter:

-

800-1300mm

-

Speed of screw:

-

50-150 RPM

-

diameter of rewinding:

-

800-1300mm

-

Dimensions:

-

13000*8300*3200

-

Gross weight:

-

AROUND 10 TONS

-

Total Power:

-

150 KW

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

Other

-

Screw Speed (rpm):

-

150 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Nanjing Sumino

-

Voltage:

-

220V or 380V or customization

-

Dimension(L*W*H):

-

customization

-

Power (kW):

-

150

-

Weight:

-

2500 KG

-

mechanical Specifications:

-

800-2300mm

-

speed of coating film:

-

100-150

-

thickness of coating film:

-

0.012~0.1mm

-

Effective screw L/D:

-

30:1

-

main unwinding diameter:

-

800-1300mm

-

Speed of screw:

-

50-150 RPM

-

diameter of rewinding:

-

800-1300mm

-

Dimensions:

-

13000*8300*3200

-

Gross weight:

-

AROUND 10 TONS

-

Total Power:

-

150 KW

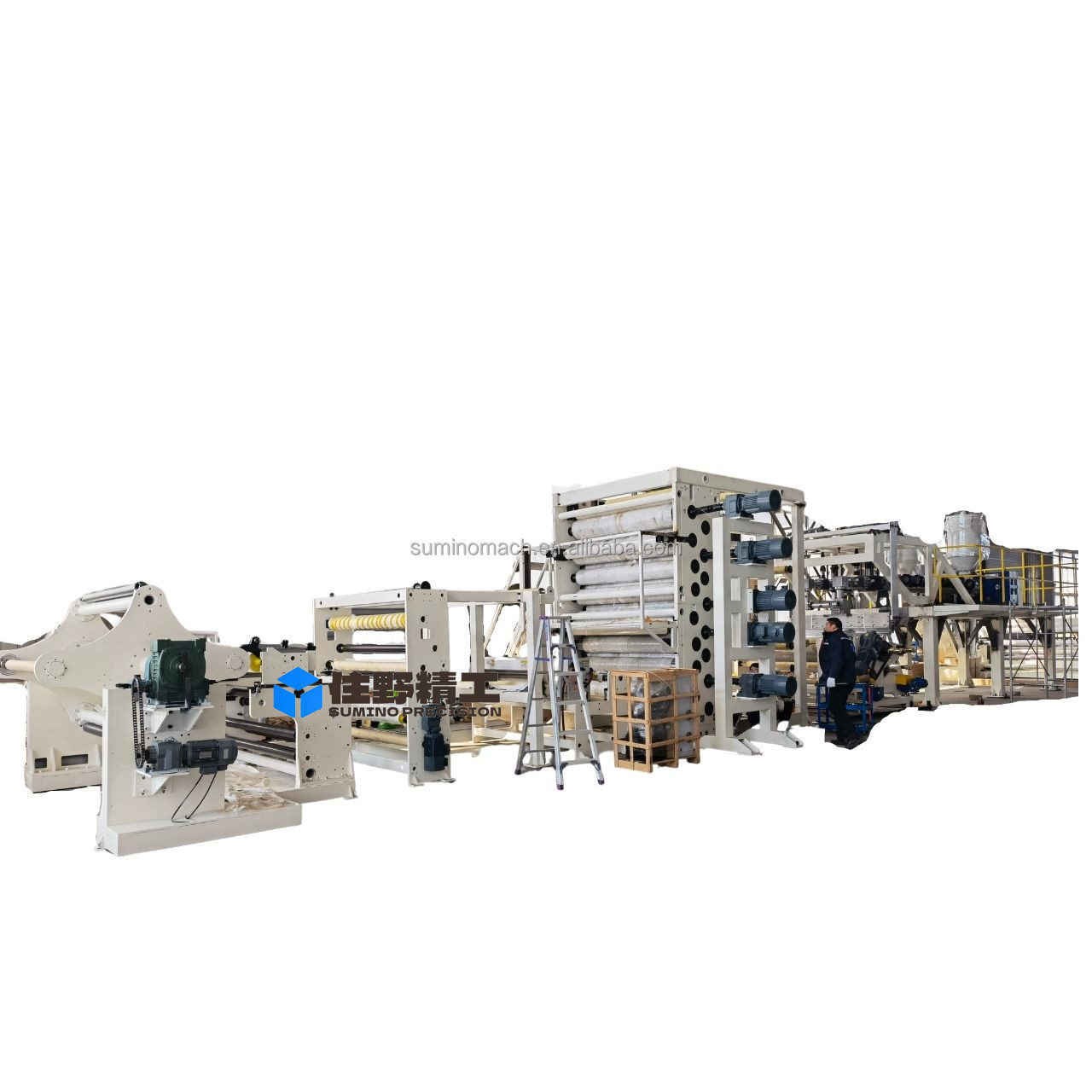

Product Paramenters

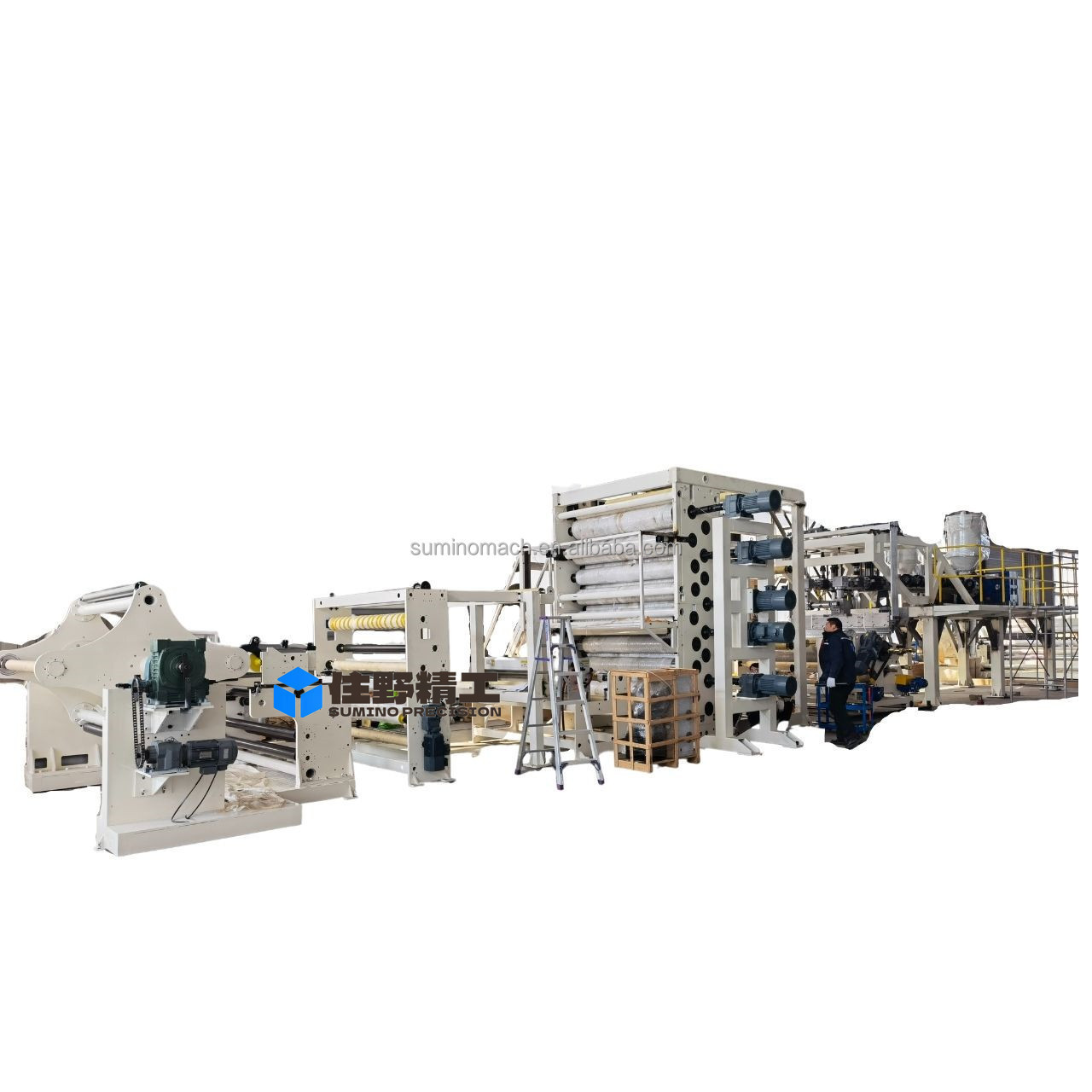

Stone Paper Making Machine/waterproof Notebook Wall Paper Stone Paper Production Plant Line

In the high temperature and high pressure process environment, calcium carbonate powder, macromolecule materials and a variety of process auxiliaries are fully mixed and milled, and then extruded by screwing.

The granules manufactured by the granulating machine are transported to the machine. After heating and strong pushing of the screw, the temperature of the raw material is raised and together with the molten PE material to be extruded into a "T" type die to form a three-layer composite sheet material, stretched by a casting roller and adjust the thickness of the product by controlling the speed, and then cooled and shaped by the cooling wheel set, and then flatten, visually inspect, thickness test,and static elimination, then cut off the ear materials and wind up the finished paper.

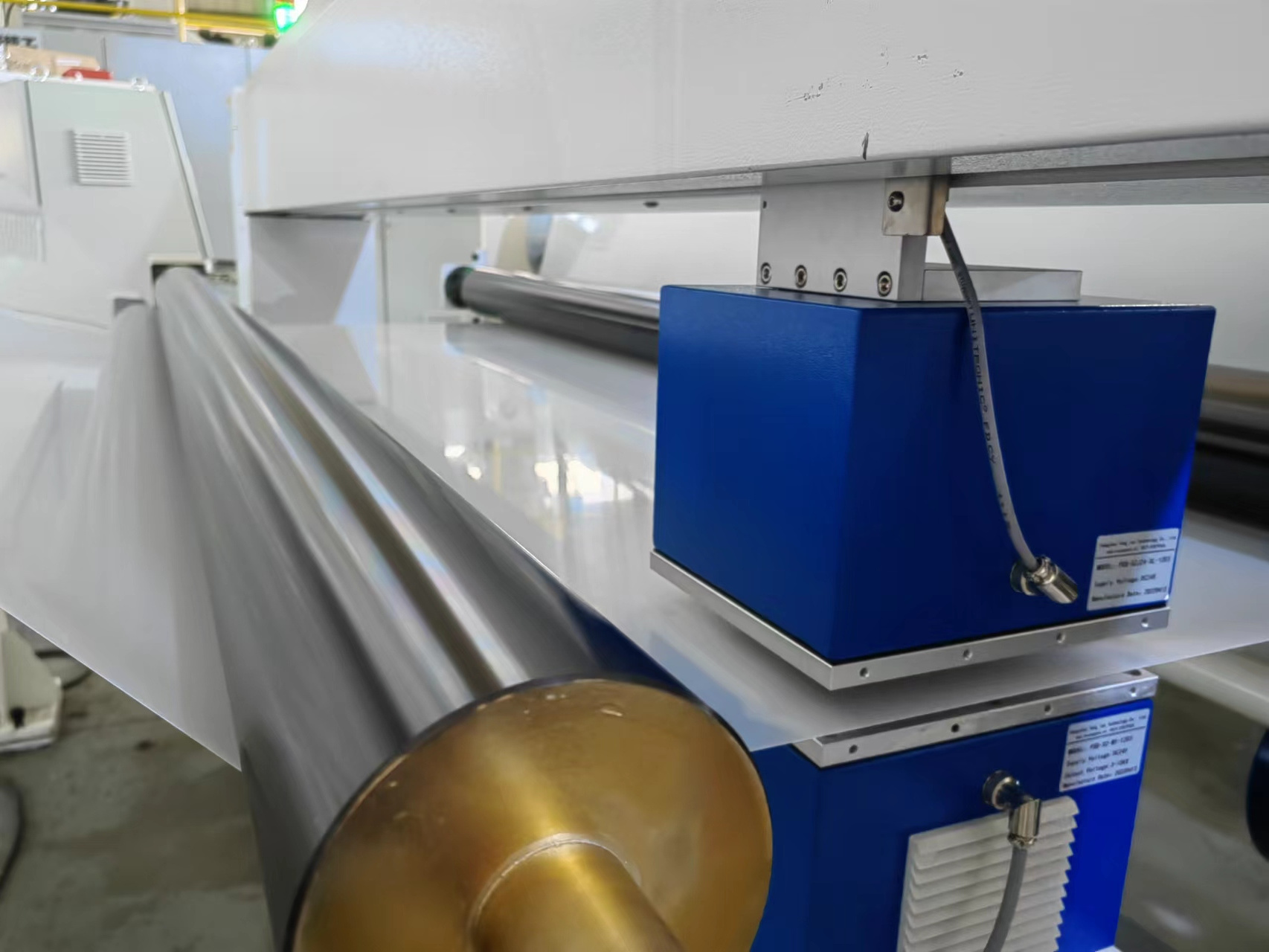

The stone paper base paper produced by the casting method is coated, firstly, the coating liquid is prepared according to the formula and then coated and produced on a coater, and the device is coated by a rotary reverse method. By forming reverse velocity difference between paper surface and coating roll erand coating feeding roller, to achieve uniform coating and stable adhesion to the paper surface. After drying in an oven, repeat the same operation to coat the back side of the paper, and finally stabilize the constant tension. The finished stone paper roll can be obtained by winding up.

Installation Instructions

Capacity

300-1200kgs/h.

Operation Environment

Temperature 5°C to 35°C; Humidity 30% to 80%; Altitude less than 1000m

Noise level

The main engine is 3 meters below 85 decibels, some fans may exceed 85 decibels, and some auxiliary equipment like fans may more

than 85 decibels.

than 85 decibels.

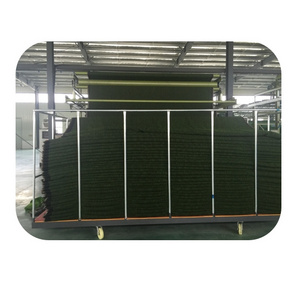

Product Application

Provide the whole production line, suitable for countries where wood is scarce.Thin paper can be used for calendar, traffic

map,notebook, brochure, stationery books, trademarks, posters, hanging tags, various handbags, wrapping paper,

map,notebook, brochure, stationery books, trademarks, posters, hanging tags, various handbags, wrapping paper,

wallpaper, large advertising etc.

Hot Searches