Hydraulic butt fusion welding machine Suitable for welding of plastic pipes and fittings made of PE,PP, and PVDF.

Automatic butt welding machine can be operated in any complex work condition.

Thermofusion welding machine welds HDPE, PP pipes and fittings for the transportation of gas, water and other fluids.

- Product Details

- {{item.text}}

Quick Details

-

Input Voltage:

-

220V

-

Dimensions:

-

315-90mm

-

Use:

-

Building weld HDPE pipes and fittings

-

Power (kW):

-

1.7

-

Weight (KG):

-

50 KG

-

Product name:

-

HDPE pipe butt fusion welding machine

-

Material:

-

High Strength Metal

-

Name:

-

HDPE pipe butt fusion welding machine

-

Function:

-

Weld Plastic Pipes

-

For Application Range:

-

Welding HDPE

-

Welding material:

-

HDPE PE PVDF

-

Certificate:

-

CE Certificate Approved

-

For Suitable Materials:

-

PVDF PP PE

-

Heat Temperature:

-

170-250℃

-

Application:

-

Building weld HDPE pipes and fittings

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

MM-Tech

-

Input Voltage:

-

220V

-

Dimensions:

-

315-90mm

-

Use:

-

Building weld HDPE pipes and fittings

-

Power (kW):

-

1.7

-

Weight (KG):

-

50 KG

-

Product name:

-

HDPE pipe butt fusion welding machine

-

Material:

-

High Strength Metal

-

Name:

-

HDPE pipe butt fusion welding machine

-

Function:

-

Weld Plastic Pipes

-

For Application Range:

-

Welding HDPE

-

Welding material:

-

HDPE PE PVDF

-

Certificate:

-

CE Certificate Approved

-

For Suitable Materials:

-

PVDF PP PE

-

Heat Temperature:

-

170-250℃

-

Application:

-

Building weld HDPE pipes and fittings

butt welding equipment for PP, PB, PE, PVDF thermoplastic material of pipes and fittings on site operation

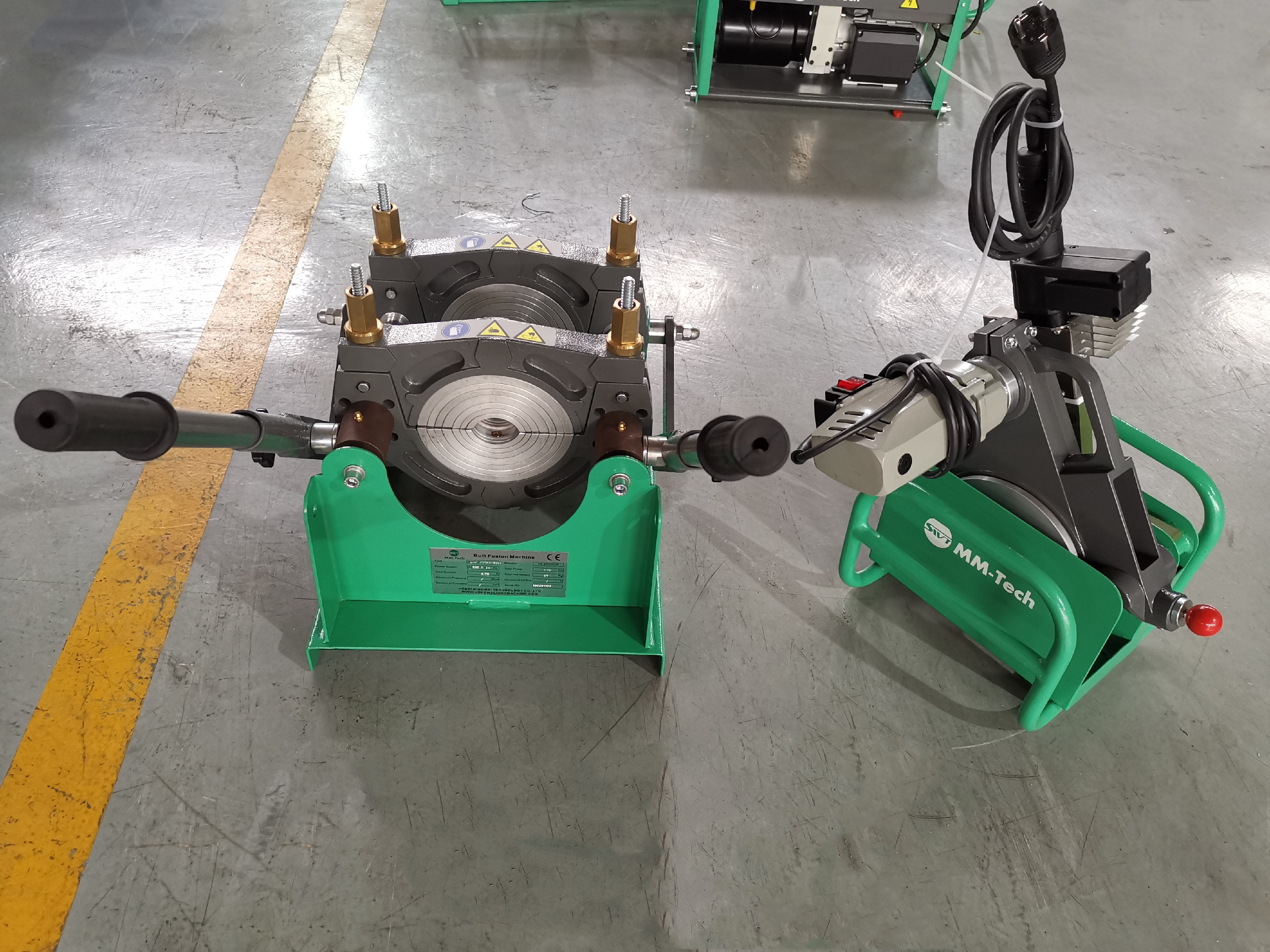

Butt Fusion Joining machine for Field Joining of Polyethylene Pipe SWT-V315/90H

Butt Fusion Joining machine for Field Joining of Polyethylene Pipe SWT-V315/90H

Product Description

SWT-V315H is hydraulic butt fusion welder. It is used to butt weld pipe and fittings such as elbow, tees, wye and flange necks without any additional equipment by simply adjusting the clamps drag bar.

It is suitable for welding plastic pipe and fittings made of HDPE, PP, PVDF.

Removable PTFE coated heating plate with separate temperature control system.

Electrical planning tool;

Be made of lightweight and high strength material; simple structure, small and delicate user friendly;

Low starting pressure ensures reliable welding quality of small pipes;

Separate two-channel timer shows time in soaking and cooling phases;

High-accurate and shockproof pressure meter in indicates clear readings.

It is suitable for welding plastic pipe and fittings made of HDPE, PP, PVDF.

Removable PTFE coated heating plate with separate temperature control system.

Electrical planning tool;

Be made of lightweight and high strength material; simple structure, small and delicate user friendly;

Low starting pressure ensures reliable welding quality of small pipes;

Separate two-channel timer shows time in soaking and cooling phases;

High-accurate and shockproof pressure meter in indicates clear readings.

V315 includes:

A machine body with 4clamps and 2hydraulic cylinders with fast couplings;

A Teflon coated heating plate with separate temperature control system;

A electrical milling cutter;

Hydraulic hoses with quick couplings;

Support for milling cutter and heating plate.

A Teflon coated heating plate with separate temperature control system;

A electrical milling cutter;

Hydraulic hoses with quick couplings;

Support for milling cutter and heating plate.

Available options:

Data logger;

Support roller;

Stub end holder;

Different inserts (single insert, ISO inserts).

Support roller;

Stub end holder;

Different inserts (single insert, ISO inserts).

Parameters

|

Technical Parameters

|

V315

|

|

Welding Range O.D.

|

90-315 mm

|

|

Power Supply

|

220V±10%, 50/60Hz

|

|

Rated Power

|

5.25 kw

|

|

Working Pressure Range

|

0-80 bar

|

|

Piston Area

|

20.02 cm2

|

|

Temperature Range

|

Max. 320ºC

|

|

Packing dimension

|

930*620*630 mm

|

|

|

630*600*730 mm

|

|

|

650*340*380 mm

|

|

Gross Weight

|

241 kgs

|

Why choose us

Product quality is guaranteed

Professional team with good service

Complete after-sales service to solve your worries

Aplication

Application of welding of polyethylene piping by thermofusion :

Pictures

Jobsite

Exhibition

We always provide high quality products and workable price for every clients and have won the trust, enjoy a good reputation in the market.

Machine Quality Guarantee: 24 months.--If any parts broken or does not work under normal operating, we provide them for free:

--

Oscar Lao

Area Sales Manager

Machine Quality Guarantee: 24 months.--If any parts broken or does not work under normal operating, we provide them for free:

--

Oscar Lao

Area Sales Manager

FAQ

Q&A:

1. PAYMENT TERMS

We accept 30% TT deposit and 70% balance payment against photo before delivery or 100% TT in advance.

2. LEAD TIME

Usually, we have plenty of stock for V355 and below, and keep max. 3units for V450 and V630. As to V800 and above, we'll arrange

production according to the actual orders.

3. WARRANTY

2 YEARS. During the warranty period, MM-Tech authorized dealer and MM-Tech will totally cover the responsibility to fix the machine;

Claim parts usually could be couriered to clients within 3days since receiveing the claim. Express fee will be borned by MM-Tech.

4. CAN YOU DO CUSTOMIZED DESIGN

YES. MM-Tech has its own design and technical team that can undertake OEM and ODM, but there are quantity requirements, please

contact our sales consultant for more information, thank you.

5. CAN YOU PROVIDE TRAINING CLASS ?

1. Customers are welcome to come to our factory for 1-2 weeks of training, in addition to air tickets and hotels, RIYANG can

afford meals and local transportation costs.

2. We can also arrange for technical personnel to fly to the customer's local to do on-site training, for a period of 1-2 weeks,

customers bear air tickets, hotels, catering, as well as technical training fees, please contact our sales consultant for details.

3.MM-Tech offers online training in English and Spanish, which requires an appointment in advance.

6. HOW COULD BE YOUR DISTRIBUTOR AT LOCAL?

MM-Tech welcomes customers from all over the world to negotiate agency business, but for agents, we have specific requirements,

details please contact our sales consultant, thank you!

1. PAYMENT TERMS

We accept 30% TT deposit and 70% balance payment against photo before delivery or 100% TT in advance.

2. LEAD TIME

Usually, we have plenty of stock for V355 and below, and keep max. 3units for V450 and V630. As to V800 and above, we'll arrange

production according to the actual orders.

3. WARRANTY

2 YEARS. During the warranty period, MM-Tech authorized dealer and MM-Tech will totally cover the responsibility to fix the machine;

Claim parts usually could be couriered to clients within 3days since receiveing the claim. Express fee will be borned by MM-Tech.

4. CAN YOU DO CUSTOMIZED DESIGN

YES. MM-Tech has its own design and technical team that can undertake OEM and ODM, but there are quantity requirements, please

contact our sales consultant for more information, thank you.

5. CAN YOU PROVIDE TRAINING CLASS ?

1. Customers are welcome to come to our factory for 1-2 weeks of training, in addition to air tickets and hotels, RIYANG can

afford meals and local transportation costs.

2. We can also arrange for technical personnel to fly to the customer's local to do on-site training, for a period of 1-2 weeks,

customers bear air tickets, hotels, catering, as well as technical training fees, please contact our sales consultant for details.

3.MM-Tech offers online training in English and Spanish, which requires an appointment in advance.

6. HOW COULD BE YOUR DISTRIBUTOR AT LOCAL?

MM-Tech welcomes customers from all over the world to negotiate agency business, but for agents, we have specific requirements,

details please contact our sales consultant, thank you!

Hot Searches