- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

0.9*18m

-

Weight:

-

3600 KG

-

name:

-

ball mill casting liners

-

application:

-

to grind different hard material into powder

-

structure:

-

firm and compact

-

raw material:

-

good steel

-

color:

-

as requirement

-

warranty:

-

quality certificate

-

spare parts:

-

supply for the whole year

-

installation:

-

under the engineer's guidance

-

operate training:

-

for free

-

After sale service:

-

Engineer Overseas

Quick Details

-

Capacity(t/h):

-

0.65-90 t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONGKE

-

Dimension(L*W*H):

-

0.9*18m

-

Weight:

-

3600 KG

-

name:

-

ball mill casting liners

-

application:

-

to grind different hard material into powder

-

structure:

-

firm and compact

-

raw material:

-

good steel

-

color:

-

as requirement

-

warranty:

-

quality certificate

-

spare parts:

-

supply for the whole year

-

installation:

-

under the engineer's guidance

-

operate training:

-

for free

-

After sale service:

-

Engineer Overseas

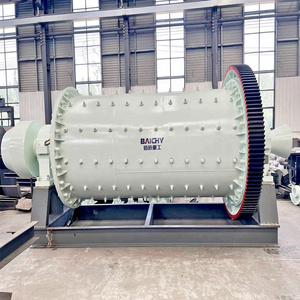

Introduction of Ball Mill

Wet/Dry Ball Mill

Overview of wet ball mill:

The wet ball mill is a key equipment for regrinding, which is widely used for cement, silicate product, new type building material, refractory material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. The ball mill can grindore or other materials that can be grinded either by wet process or by dry process.

Wet ball mill is new ball mill according to new concept design which adopts special rolling bearing as support structure of barrel. It solves service life of overload rolling bearing and problem of regulating mental activities, sealing problem under severe environmental condition and barrel movement caused by long working hours.

Wet Ball Mill Working Principle:

The wet ball mill is a horizontal cylinder rotating device. It is equipped with drive gear which drives the cylinder for rotation in the working process outside the cylinder. There are two chambers. Materials go into the first chamber of the grinding machine spirally and evenly through the feeding hollow shaft from the feeding device, and there are ladder lining plates or ripple lining plates inside the first chamber where there are different kinds of steel balls. When the cylinder rotates, it will produce eccentric force to bring the steel balls to a certain height, the steel balls will fall down to impact and grind the materials.

After being coarsely grinded in the first chamber, the materials will go into the secondary chamber where there are flat lining plates through the single-layer partition board. There are steel balls for further grinding the materials in the lining plate, and steel ball is set inside the second chamber. Materials will be grinded. Finally the powdery materials will be discharged from the discharging grating bar to complete powder grinding operation.

The wet ball mill is a key equipment for regrinding, which is widely used for cement, silicate product, new type building material, refractory material, chemical fertilizer, black and non-ferrous metal, glass, ceramics and etc. The ball mill can grindore or other materials that can be grinded either by wet process or by dry process.

Wet ball mill is new ball mill according to new concept design which adopts special rolling bearing as support structure of barrel. It solves service life of overload rolling bearing and problem of regulating mental activities, sealing problem under severe environmental condition and barrel movement caused by long working hours.

Wet Ball Mill Working Principle:

The wet ball mill is a horizontal cylinder rotating device. It is equipped with drive gear which drives the cylinder for rotation in the working process outside the cylinder. There are two chambers. Materials go into the first chamber of the grinding machine spirally and evenly through the feeding hollow shaft from the feeding device, and there are ladder lining plates or ripple lining plates inside the first chamber where there are different kinds of steel balls. When the cylinder rotates, it will produce eccentric force to bring the steel balls to a certain height, the steel balls will fall down to impact and grind the materials.

After being coarsely grinded in the first chamber, the materials will go into the secondary chamber where there are flat lining plates through the single-layer partition board. There are steel balls for further grinding the materials in the lining plate, and steel ball is set inside the second chamber. Materials will be grinded. Finally the powdery materials will be discharged from the discharging grating bar to complete powder grinding operation.

Working principle of ceramic ball mill

The motor on the ceramic ball mill drives the cylinder rotation through the deceleration device, and then the crushed ore and grinding ball in the cylinder are brought to a certain height by friction and centrifugal force when the cylinder rotates, and after the liner is brought to a certain height due to gravity, it will be thrown and falling and the ore will be gradually crushed under the action of impact and grinding. The crushed stone is discharged through the discharge part.

After the discharged material is classified into a qualified product in the spiral classifier, the coarse sand is returned to the ball mill through the combined feeder to continue grinding. The feeder feeds continuously and evenly, and the ore enters the ceramic ball mill continuously and evenly through the combined feeder, and the ground material is continuously discharged from the ceramic ball mill. Ceramic ball mill is a grinding equipment that can work continuously 24 hours a day.

After the discharged material is classified into a qualified product in the spiral classifier, the coarse sand is returned to the ball mill through the combined feeder to continue grinding. The feeder feeds continuously and evenly, and the ore enters the ceramic ball mill continuously and evenly through the combined feeder, and the ground material is continuously discharged from the ceramic ball mill. Ceramic ball mill is a grinding equipment that can work continuously 24 hours a day.

Internal Structure of Ceramic Ball Mill

Although ceramic liner ball mills and ordinary ball mills have similar shapes and working principles, ceramic liner ball mills have unique advantages in many industries, which are also not available in ordinary ball mills. For example, in the mineral processing industry, many of the grinding processes of raw materials cannot have the participation of iron metal, therwise the quality and value of the finished product will be greatly affected. At this time, it is necessary to choose a mill with ceramic liner. In addition, the ceramic liner is very wear-resistant, the service life is also greatly extended, for the same material, the service life of the ceramic liner ball mill liner can be extended at least several times.

Applicable materials

Wet and dry operation, It is used for fine grinding of feldspar, quartz, clay, ore and other raw materials.

Technical Parameters

|

Model

|

Shell rotation speed

(r/min) |

Ball load

(t) |

Feeding size

(mm) |

Discharging size

(mm) |

Capacity

(t/h) |

Motor power

(kw) |

Total weight

(t) |

|

900×1800

|

36-38

|

1.5

|

≤20

|

0.075-0.89

|

0.65-2

|

18.5

|

5.5

|

|

900×3000

|

36

|

2.7

|

≤20

|

0.075-0.89

|

1.1-3.5

|

22

|

6.7

|

|

1200×2400

|

36

|

3

|

≤25

|

0.075-0.6

|

1.5-4.8

|

30

|

12

|

|

1200×3000

|

36

|

3.5

|

≤25

|

0.074-0.4

|

1.6-5

|

37

|

12.8

|

|

1200×4500

|

32.4

|

5

|

≤25

|

0.074-0.4

|

1.6-5.8

|

55

|

13.8

|

|

1500×3000

|

29.7

|

7.5

|

≤25

|

0.074-0.4

|

2-5

|

75

|

16.8

|

|

1500×4500

|

27

|

11

|

≤25

|

0.074-0.4

|

3-6

|

110

|

21

|

|

1500×5700

|

28

|

12

|

≤25

|

0.074-0.4

|

3.5-6

|

130

|

25.8

|

|

1830×3000

|

25.4

|

11

|

≤25

|

0.074-0.4

|

4-10

|

130

|

29

|

|

1830×4500

|

25.4

|

15

|

≤25

|

0.074-0.4

|

4.5-12

|

155

|

35.5

|

|

1830×6400

|

24.1

|

21

|

≤25

|

0.074-0.4

|

6.5-15

|

210

|

43

|

|

1830×7000

|

24.1

|

23

|

≤25

|

0.074-0.4

|

7.5-17

|

245

|

43.8

|

|

2100×3000

|

23.7

|

15

|

≤25

|

0.074-0.4

|

6.5-36

|

155

|

34.8

|

|

2100×4500

|

23.7

|

24

|

≤25

|

0.074-0.4

|

8-43

|

245

|

42

|

|

2100×7000

|

23.7

|

26

|

≤25

|

0.074-0.4

|

8-48

|

280

|

56.6

|

|

2200×4500

|

21.5

|

27

|

≤25

|

0.074-0.4

|

9-45

|

280

|

51.8

|

|

2200×6500

|

21.7

|

35

|

≤25

|

0.074-0.4

|

14-26

|

380

|

60

|

|

2200×7000

|

21.7

|

35

|

≤25

|

0.074-0.4

|

15-28

|

380

|

62

|

|

2200×7500

|

21.7

|

35

|

≤25

|

0.074-0.4

|

15-30

|

380

|

64.8

|

Introduction of Air Swept Ball Mill

The Introduction of Air Swept Ball Mill

Air Swept Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation. If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed.

Features

Features

1) Ball mill is an efficient tool for grinding many materials into fine powder.

2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine

3) Ball mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to differentexpelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals.

2) The ball mill is used to grind many kinds of mine and other materials, or to select the mine

3) Ball mill is widely used in building material, and chemical industry.

4) There are two ways of grinding: the dry way and the wet way.

5) Ball mill can be divided into tabular type and flowing type according to differentexpelling mine

6) To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

7) As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product into fine powder over a period of several hours.

8) The longer the ball mill runs, the finer the powder will be.

9) Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

10) Our ball mills have been used to grind glass, powder food products, create custom varnishes, make ceramic glaze, powder various chemicals.

Company Introduction

Aerial view of the factory

Factory photo taken

Factory workshop actual photos

⭐

About US

⭐

Henan Hongke Heavy Machinery Cp,,Ltd is a research and development, production and sales in one professional group,It is the rapid rise dazzling star in machinery industry by the economy development of China

We are specialized in grinding, crushing, drying,rotary kiln product development and production of high-tech enterprises, including lime kiln State Environment Protection Agency recommended products.The company developed the Raymond mill, ulyrafine mill, dryer, rotary kiln, series crusher,stone crusher, vibrating screen series, jaw crusher, hammer crusher, impact crusher, cone crusher, Sand and gravel production line—— ( sand production line), and other devices with the leading domestic level, some products have reached the international advanced level.Two years of wind and rain entrepreneurship, Acer Branch who never gave up.Full cast Plains, the company brings together a large number of innovation, on behalf of the national level of the industry's outstanding scientific research and management personnel, created a unity march, strict and efficient workforce.To meet the business development and market competition, the company has built a first-class modern production and testing base, nationwide sales network,the company early ten thousand users to provide good services. Companies adhere to the " Industrial quality" start thinking of pursing a "customer satisfaction" principle of service to "good faith,seek truth from facts"for the operation of the country. Won the " quality of the letter units" and other honorary title, " wang section" trademark has become a kiln, a symbol of the mill product credibility."Product quality is the life", the company to modern management , better technology, advanced production equipment and strict means testing, introduced various types of high-quality industrial rotary kiln , milling machines and dryers and other products. The company will continue to hold high the Industrial serve the country, the conomic revitalization of the Chinese nation," the banner, dedication and four Haibin friends and create brilliant, jointly hold the Chinese solar industry.Henan Hongke Heavy Industry Machinery Equipment Co., Ltd. is a group company integrating scientific research, production and marketing, and is a dazzling star in China's machinery industry with the rapid rise of market economy. For more than ten years, Hongke people have been self-improvement and forged in the Central Plains.

The company has brought together a large number of scientific research and management talents who are determined to innovate and represent the level of the industry, creating a united and forging ahead and strict staff. The company has established rotary kiln production line, Raymond mill, dryer, sand making machine, ball mill, pre-crusher and other production lines. In order to meet the needs of enterprise development and market competition, the company has built a modern production base: covering the domestic sales and service network, providing thoughtful services for nearly 10,000 users of the company.

Advantages of Our Factory:

1) Has almost 20 years experience

2) Owning the biggest workshop and advanced equipments in the industry

3) Strict management and good prestige

Advantages of Our Equipments:

1) Advance technics and standard testing

2) Strict quality control system

3) Have passed ISO9001: 2000 international quality certification

4) Preferential price

Advantages of Our Service:

1) Perfect service after sale

2) Design and build factory, install and run equipments, and train workers freely for our customer

3) Quality guarantee for 1 year's time, providing spare parts at cheap price

1) Has almost 20 years experience

2) Owning the biggest workshop and advanced equipments in the industry

3) Strict management and good prestige

Advantages of Our Equipments:

1) Advance technics and standard testing

2) Strict quality control system

3) Have passed ISO9001: 2000 international quality certification

4) Preferential price

Advantages of Our Service:

1) Perfect service after sale

2) Design and build factory, install and run equipments, and train workers freely for our customer

3) Quality guarantee for 1 year's time, providing spare parts at cheap price

Reasons to choose Hongke machines

1.Self-produced and self-sold, guaranteed after-sales, one-stop service allows you to buy machinery safely

2.Online customer service

3.Specialized in transporting equipment

4.Private car transfer for field trips

5.Dedicated technical guidance training

6.Professionally tailor-made solutions

7.Exclusive after-sales service system

1.Self-produced and self-sold, guaranteed after-sales, one-stop service allows you to buy machinery safely

2.Online customer service

3.Specialized in transporting equipment

4.Private car transfer for field trips

5.Dedicated technical guidance training

6.Professionally tailor-made solutions

7.Exclusive after-sales service system

Why Choose Us

To Be Your Satisfied Partner

We provide not only quality products, But solution for full set equipment!

Some Cooperated Foreign Customers

By spirit of perseverance, We will try our best to provide more new products and technical support to customers from home and abroad.

By product absolutely advantages and excellent service team

and first-class service system, Hongke has won great honors of customer form home and abroad.

Hot Searches