- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

10pcs 1/8" 3mm*6mm Tungsten Carbide Burr router file bits

-

Material:

-

YG7,K25,cemented,TCT

-

cut:

-

Standard/single/Double/ Aluminum

-

shape:

-

cylinder, cone, ball, tree,long noe,etc

-

Application:

-

die grinder, pattern making, surface cleaning and maintenance

-

Usage:

-

Mainly used in the pneumatic or electric-driven tools

-

OEM:

-

available

-

Certificate:

-

ISO 9001, CE

-

Warranty::

-

1 year

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Hebei, China, Hebei, China

-

Model Number:

-

JFXZ-006

-

Product name:

-

10pcs 1/8" 3mm*6mm Tungsten Carbide Burr router file bits

-

Material:

-

YG7,K25,cemented,TCT

-

cut:

-

Standard/single/Double/ Aluminum

-

shape:

-

cylinder, cone, ball, tree,long noe,etc

-

Application:

-

die grinder, pattern making, surface cleaning and maintenance

-

Usage:

-

Mainly used in the pneumatic or electric-driven tools

-

OEM:

-

available

-

Certificate:

-

ISO 9001, CE

-

Warranty::

-

1 year

10pcs 1/8" 3mm*6mm Tungsten Carbide Burr router file bits

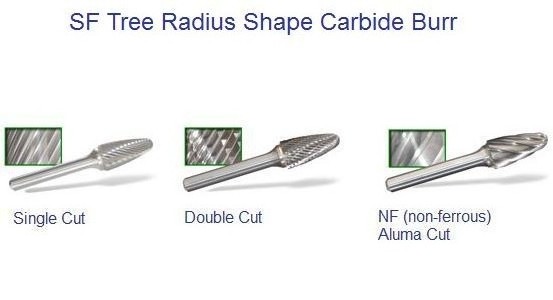

Carbide burs/porting tools for metal working. Manufactured on premium automated CNC machines, carbide burs are available in three main styles of cuts – single, double and aluma.

Single-cut burs

are for general purpose work and provide good material removal.

Double-cut burs

produce smaller chips for greater operator control on applications such as stainless steels and ferrous materials.

Aluma-cut burs

have a wide flute design for easy stock removal without loading on applications such as nonferrous and soft materials.

Standard-cut burs

are widely uesed and leave a fine finish

The carbide bur line includes more than 175 individual burs and one 10-piece kit and 5-piece kit. Overall bur lengths range carbide burs are used in many industries including automotive, aerospace, foundry, power station and engineering for mold and pattern making, die sinking, tool making and maintenance.

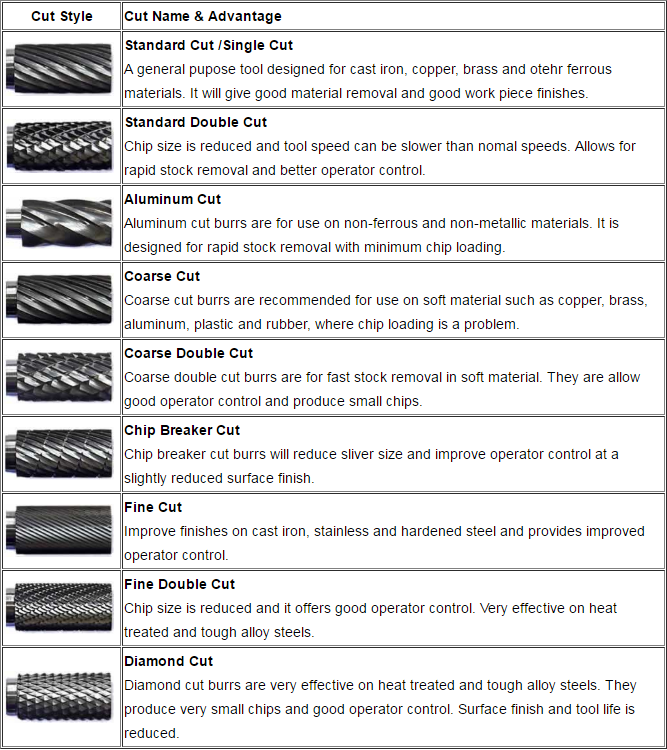

Three main cut type as below: standard single cut, standard double cut, aluminum(non-ferrous)

How to use the carbide burr

1.Speed /RPM

The speed at which you use your carbide bur in your rotary tool will depend on the material you're using it on and the contour being produced but it's safe to say you do not need to exceed speeds of 35,000 RPM. The table below shows some approximate speeds.

Diameter of Burr RPM

1.6mm or 1/16" 25,000 - 35,000

2.35mm or 3/32" 17,000 - 26,000

3mm or 1/8" 17,000 - 26,000

6mm or 1/4" 11,000 - 16,500

12mm or 1/2" 8,000 - 12,000

16mm or 5/8" 7,650 - 11,500

2.Apply only a little pressure

As with all drill bits and burrs, let the burr do the work and apply only a little pressure otherwise the cutting edges of the flutes will chip away or become smooth too quickly, reducing the life of your burr.

3.Keep The Carbide Burr On The Move

When using your carbide burr try not to keep it still for too long as this will prevent the burr from digging and jabbing into your material causing unsightly marks and roughness.

Advantage of our carbide burrs

100% quality and brand new.

Can Process a variety of metal and non-metal, processing hardness would up to HRC70.

In a great part of the work, it can replace the petiole small wheel, and no dust pollution.

High production efficiency, the processing efficiency is several times higher than file, nearly 10 times higher than small wheel stalk.

High product processing quality, high finish, can process out a various of high-precision mold cavity.

Long life, the durability is 10 times higher than high-speed steel cutting tool, 200 times higher than small grinding wheel.

Easy to use, safe and reliable, can reduce labor intensity, improve the working environment.

Suitable for processing these metal and non-metal, such as cast iron, cast steel, bearing steel, high carbon steel, chrome-nickel alloy, bronze, brass, and ceramic tile, marble, jade, bone, etc.

Tungsten carbide burr is used widely in the shipping construction, auto engine porting and foundry fabrication. With its high rotating speed and hardness, it can machine a lot of different materials like cast iron, carbon steel, alloy steel and non ferrous material. High life service of product is warranted for virgin and excellent raw material which is one of most critical factors to the tools' life.

Pls choose the proper size,shape and cut type according to the work pieces request

Delivery Time :20 days after receipt the payment. And it according to the quantity

Payment Item : 70% T/T before production, the balance before shipment

Package Details :plastic for inner package. Carton for outter package

FAQ

Q: Where is your factory?

A: Located in Nanhe, Xingtai city, Hebei Province, close to Beijing Capital international airport.

Q: Can we print our

LOGO

?

A: Yes, logo can be printed on the handle part of files or outside packing. QTY above 3000pcs will be without extra cost.

Q: Can we get

free samples

?

A: Normally samples within 10pcs is free.

Q: How long is

delivery time

?

A: Normally it will be 20 to 30 days according quantity.

Q: What's your

payment

?

A: For sample order US$500, paypal, western union or aliaba Escrow.

For first order, normally 30% in advance, 70% payment after production before delivery.