- Product Details

- {{item.text}}

Quick Details

-

Weight (T):

-

7.5 T

-

Motor Power (kw):

-

30 kw

Quick Details

-

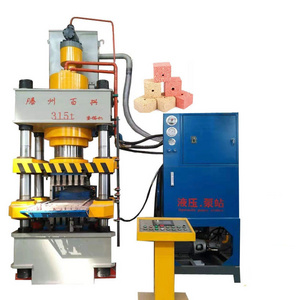

Machine Type:

-

Four-column Three-beam Hydraulic Press

-

Return Force (kN):

-

250 kN

-

Place of Origin:

-

FoShan,China

-

Weight (T):

-

7.5 T

-

Motor Power (kw):

-

30 kw

Products Description

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

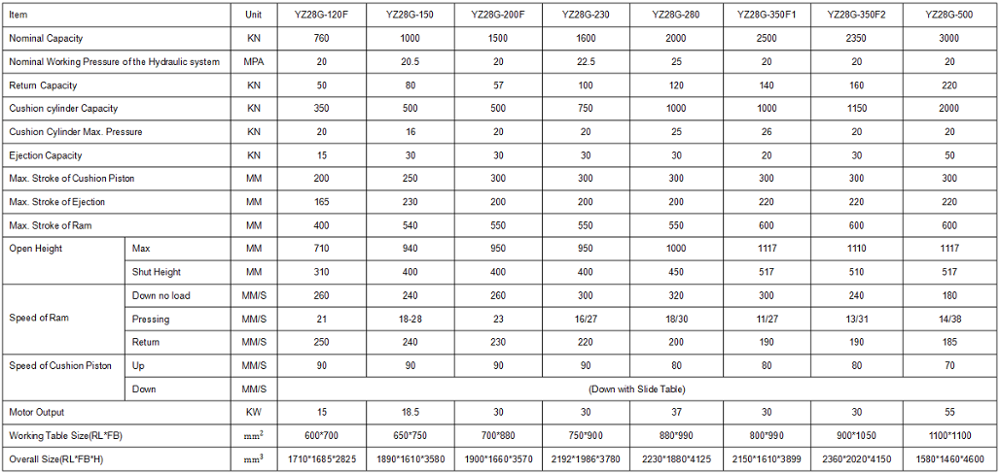

YZ28G- Hydraulic Pressing machine

This Machine is used for cookware utensil forming

Advantages

1.Efficiently

8-12s/pcs (Dia.XH:200mmX100mm),about 2500 pcs/8hours

2.Productions succeed≧99|%

Save cost in as less damage as possible

3. Feedback by clients that machine frame life over 10 years.

4. Easy maintenance.

Semi-auto lubricate system

5. Easy operation.

Unskilled ladies or freshman can operate the machine

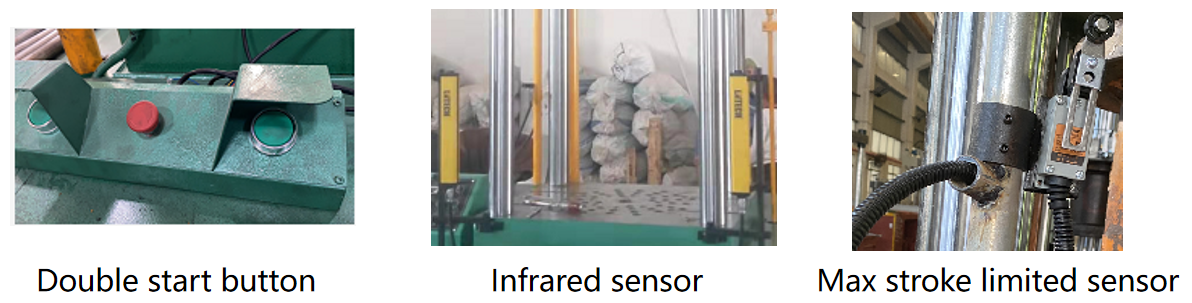

6.Three safe-protection systems

A. Double start bottom.

B. Infrared sensor protect worker safe.

C.Max stroke limited sensor protects the main cylinder and workers

7. Most of components are international brands: Omron, Schneider,Mitsubishi or Idec

8-12s/pcs (Dia.XH:200mmX100mm),about 2500 pcs/8hours

2.Productions succeed≧99|%

Save cost in as less damage as possible

3. Feedback by clients that machine frame life over 10 years.

4. Easy maintenance.

Semi-auto lubricate system

5. Easy operation.

Unskilled ladies or freshman can operate the machine

6.Three safe-protection systems

A. Double start bottom.

B. Infrared sensor protect worker safe.

C.Max stroke limited sensor protects the main cylinder and workers

7. Most of components are international brands: Omron, Schneider,Mitsubishi or Idec

|

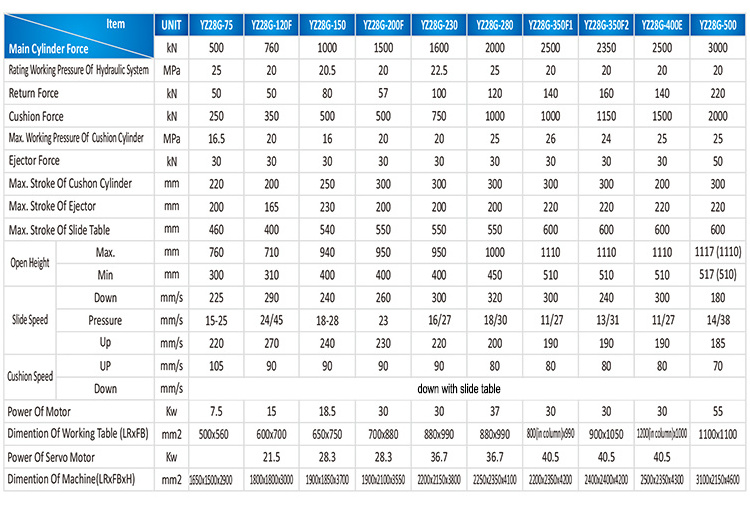

Item

|

|

UNIT

|

YZ28G-75

|

|

|

|

Main Cylinder Force

|

|

KN

|

500

|

|

|

|

Rating Working Pressing Of Hydraulic System

|

|

Mpa

|

20

|

|

|

|

Return Force

|

|

KN

|

50

|

|

|

|

Cushion Force

|

|

KN

|

250

|

|

|

|

Max. Working Pressure Of Cushion Cylinder

|

|

Mpa

|

20

|

|

|

|

Ejector Force

|

|

KN

|

20

|

|

|

|

Max. Stroke Of Cushion Cylinder

|

|

MM

|

200

|

|

|

|

Max. Stroke Of Ejector

|

|

MM

|

200

|

|

|

|

Max. Stroke Of Slide Table

|

|

MM

|

450

|

|

|

|

Open Height

|

Max.

|

MM

|

700

|

|

|

|

|

Min.

|

MM

|

250

|

|

|

|

Slide Speed

|

Down

|

MM/S

|

270

|

|

|

|

|

Pressure

|

MM/S

|

30-50

|

|

|

|

|

Up

|

MM/S

|

270

|

|

|

|

Cushion Speed

|

Up

|

MM/S

|

100

|

|

|

|

|

Down

|

MM/S

|

Down with slide table

|

|

|

|

Power Of Motor

|

|

KW

|

7.5

|

|

|

|

Dimension Of Working Table

|

|

MM ²

|

490*550

|

|

|

|

Dimension Of Machine(LR*FB*H)

|

|

MM ²

|

1570*1270*2800

|

|

|

Details Images

Three safe-protection systems

International brand

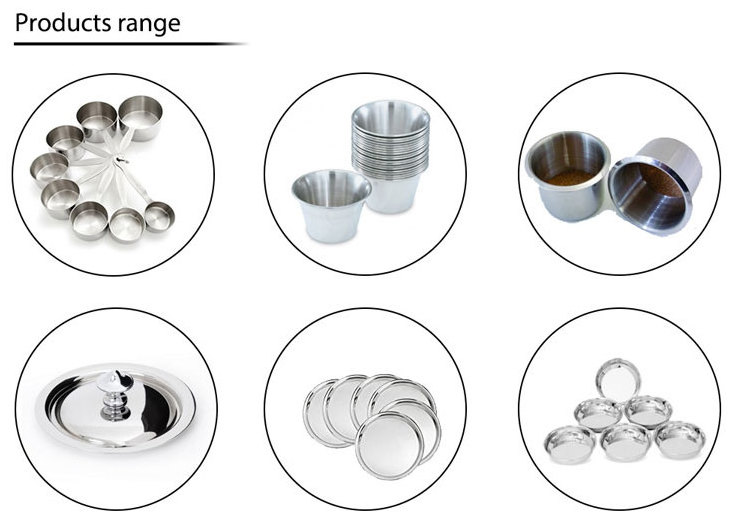

What you can make

*Wrapped by film and packed with fumigated wooden case or Steel frame pallet for container.

About Us

Why Choose us

What you can get from Sunglory

1.Measure and evaluate project on-site

2.Plan the whole factory & design processes flow

3.Manufacture machines, tools

4.QC&pre-acceptance before shipment

5.Overseas installation, commissioning and training

6.Final acceptance by trial production Click here to get more

Our company can provide customers with one-stop solutions based on customer's

sample/product drawings/product physical/machine

Project We Have Done

We have done 37 A-Z projects

Bangladesh A-Z project, aluminum & stainless steel pot

Algeria A-Z project, aluminum & stainless steel couscous

Indonesia aluminum pot

Exhibition

lt is our mission to continuously improve the quality of your products and expand your market share to help you succeed, to your wealth and achieve your dreams, and ultimately to benefit the family happiness of world people and to be good for the earth.

Certifications

FAQ

Q:I want to manufacture pots and pans, what kind of machine do I need and what’s the budget?

A:Before we quote and supply solutions, we need details of product information(product material/thickness), product pictures, daily production etc..

Q:I also need relative consumable, could you provide to me together?

A:Yes. We provide turn key project, from raw material to equipment for final products, mold, parts and relative consumables, such as polish wheel, handle etc.

Q:How do you ensure if your equipment is suitable for my product?

A:We have a perfect service system. Firstly, our pre-sale service require us to do process feasibility analysis. In addition, we would simulate production according to customer’s future production condition and inform customer to inspect goods at spot before machine shipment which is our in-sale service. Also we provide machine installation abroad and training.

Q:I am a new, I want to make cookware, How I start?

A:First go you the market that you want to sell your cookware, then find the Hot sell products. Make one market survey know your market. Then send the samples and detail for us, our team will offer your turn-key solution.

Q:How machine package?

A:Iron frame and three plywood by LCL

Film and wire are fixed at FC.

Q:What time can start the project?

A:If single machine 60 days finish produce, 7 days testing samples, packing and prepare shipping 7days, shipping 7-30days on sea. Clearance and reaching your factory 3 weeks. Prepare to work before commissioning 10 days. Engineer coming service 7 days.

If full production line 60-90days finish machine, 15 days testing samples, packing acking and prepare shipping 14 days, shipping 7-30days on sea. Clearance and reaching your factory 3 weeks. Prepare to work before commissioning 15 days. Engineer coming service 30 days.

Hot Searches