- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

different boiler different size

-

Weight:

-

0.4T-4T

-

Item:

-

50kg-1000kg mini boilers oil and gas hot water boiler Italy burner

-

Useage:

-

china supplier oil gas hot water boiler for heating swimming pool

-

Type of boiler:

-

vertical oil and gas hot water boiler

-

Experience in oil gas hot water boiler:

-

more than 20 years

-

Working pressure:

-

0.4-1.0MPa

-

Design efficiency:

-

90%

-

Voltage:

-

380v

-

Thermal efficiency:

-

more than 94%

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE ASME GOST GB AS ISO9001

Quick Details

-

Core Components:

-

Burner, Pump, Electric control

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

EPCB

-

Dimension(L*W*H):

-

different boiler different size

-

Weight:

-

0.4T-4T

-

Item:

-

50kg-1000kg mini boilers oil and gas hot water boiler Italy burner

-

Useage:

-

china supplier oil gas hot water boiler for heating swimming pool

-

Type of boiler:

-

vertical oil and gas hot water boiler

-

Experience in oil gas hot water boiler:

-

more than 20 years

-

Working pressure:

-

0.4-1.0MPa

-

Design efficiency:

-

90%

-

Voltage:

-

380v

-

Thermal efficiency:

-

more than 94%

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Certification:

-

CE ASME GOST GB AS ISO9001

Products Description

Epcb 50kg-1000kg Mini Boilers Duel Fuel Boiler Oil And Gas Hot Water Boiler with Italy Burner

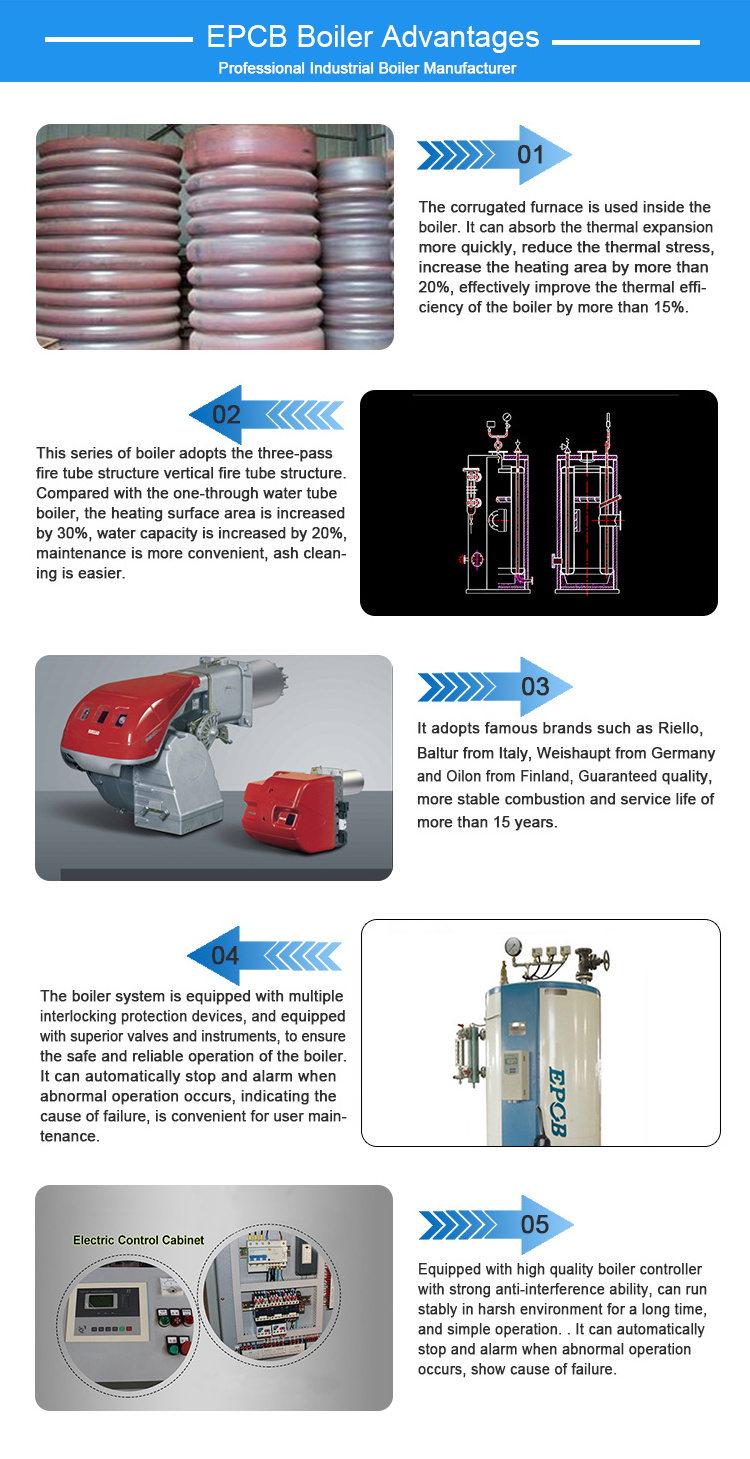

Product Advantages:

1. The structure that surround the combustion chamber with water avoids the heat losing, saves energy and reduces the operation cost.

2. The shell and fire pipe are made of special material, and adopt European and American standard thickness, high strength, safety, stability and reliability, and long service life.

3. Reliable boiler auxiliary and various safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

4.Large heating surface; high thermal efficiency; precise temp. Control; Clean combustion, less pollution; The emission standard is superior to the most stringent standard in Europe.

2. The shell and fire pipe are made of special material, and adopt European and American standard thickness, high strength, safety, stability and reliability, and long service life.

3. Reliable boiler auxiliary and various safety protection devices, such as pressure controller, pressure transmitter, water level alarm, safety valve, etc.

4.Large heating surface; high thermal efficiency; precise temp. Control; Clean combustion, less pollution; The emission standard is superior to the most stringent standard in Europe.

Product Paramenters

|

Item\Model

|

|

Vertical Fire Tube Oil/Gas Fired Steam Boiler

|

|

|

|

|

|

|

|

||||||||

|

Rated heat capacity kw

|

|

60

|

80

|

120

|

180

|

230

|

350

|

470

|

580

|

||||||||

|

Rated heat power Kcal/h

|

|

5x10^4

|

7x10^4

|

10x10^4

|

15x10^4

|

20x10^4

|

30x10^4

|

40x10^4

|

50X10^4

|

||||||||

|

Rated working pressure MPa

|

|

0

|

|

|

|

|

|

|

|

||||||||

|

Supply/return water temperature ℃

|

|

85/60

|

|

|

|

|

|

|

|

||||||||

|

Design heat efficiency %

|

|

≧90

|

|

|

|

|

|

|

|

||||||||

|

Heating area m²

|

|

1.85

|

2.3

|

3.25

|

6.45

|

6.9

|

10.8

|

14.5

|

15.2

|

||||||||

|

Boiler water capacity m3

|

|

0.126

|

0.17

|

0.222

|

0.316

|

0.371

|

0.783

|

0.93

|

1.751

|

||||||||

|

Flue diameter mm

|

|

Φ108

|

Φ160

|

Φ160

|

Φ250

|

Φ250

|

Φ250

|

Φ250

|

Φ280

|

||||||||

|

Feed water diameter DN

|

|

40

|

50

|

50

|

65

|

65

|

65

|

65

|

80

|

||||||||

|

Blowdown tube diameter DN

|

|

50

|

40

|

50

|

50

|

50

|

50

|

50

|

50

|

||||||||

|

Fuel consumption

|

Diesel kg/h

|

4.8

|

6.3

|

9.5

|

14.3

|

18.2

|

27.7

|

37.2

|

45.9

|

||||||||

|

|

Natural gas Nm³/h

|

5.7

|

7.6

|

11.4

|

17.0

|

21.8

|

33.1

|

44.5

|

54.9

|

||||||||

|

|

LPG Nm³/h

|

2.1

|

2.8

|

4.2

|

6.3

|

8.0

|

12.2

|

16.4

|

20.2

|

||||||||

|

Boiler size

|

L mm

|

700

|

800

|

800

|

1100

|

1100

|

1300

|

1200

|

1450

|

||||||||

|

|

W mm

|

800

|

900

|

900

|

1000

|

1000

|

1400

|

1150

|

1400

|

||||||||

|

|

H mm

|

1350

|

1600

|

1700

|

1800

|

1980

|

2140

|

2280

|

2270

|

||||||||

|

Transportation weight kg

|

|

220

|

260

|

320

|

480

|

500

|

800

|

910

|

1400

|

||||||||

Product packaging

We choose the best way to pack and load our boilers. All parts will be complete and work well. Professional factory offers. professional and safety service.

Why Choose Us

Quality:

The boiler is an A grade boiler, EPCB is an A1, A2 grade pressure vessel manufacturing company. All products have passed ISO9001, EAC & ASME International Quality Management System Certification also can provide CE, AS and COST certification. And we can also conduct local certification according to your actual certification needs.

The boiler is an A grade boiler, EPCB is an A1, A2 grade pressure vessel manufacturing company. All products have passed ISO9001, EAC & ASME International Quality Management System Certification also can provide CE, AS and COST certification. And we can also conduct local certification according to your actual certification needs.

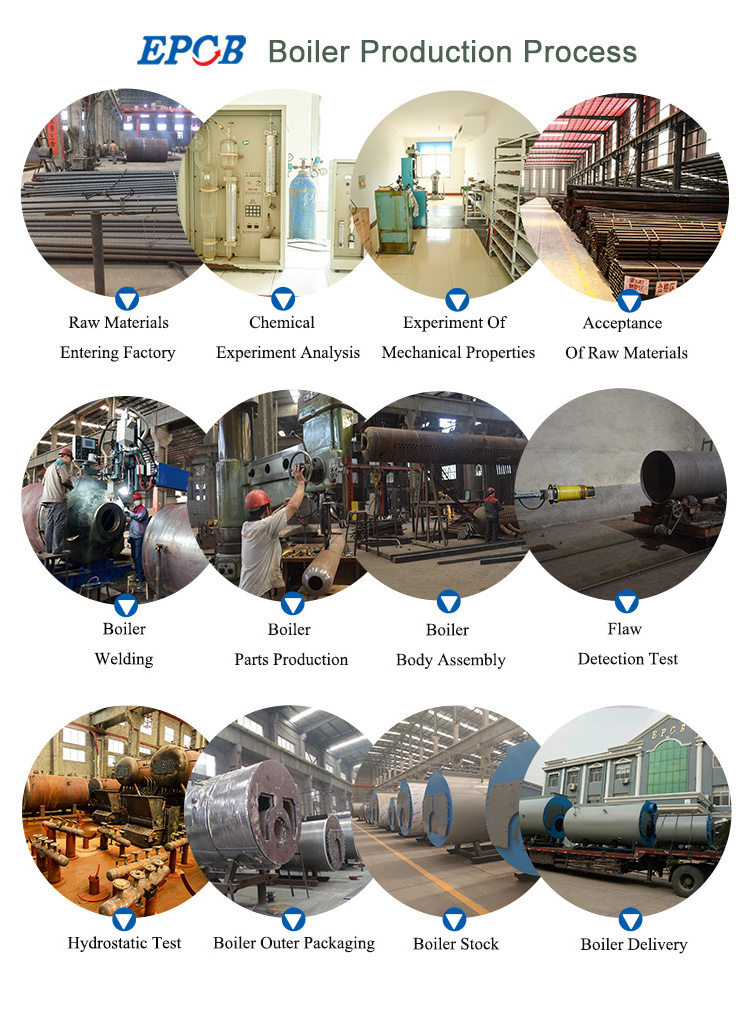

Management:

In order to ensure quality, we strictly monitor the purchase, retest, and storage of raw materials. All steel pipes are from the top ten steel suppliers in the world, and then we conduct physical and chemical tests on them, and then we cooperate with the top four suppliers in them. Before the materials enter the factory, we need to check again. This process is repeated once a year.

In order to ensure quality, we strictly monitor the purchase, retest, and storage of raw materials. All steel pipes are from the top ten steel suppliers in the world, and then we conduct physical and chemical tests on them, and then we cooperate with the top four suppliers in them. Before the materials enter the factory, we need to check again. This process is repeated once a year.

Welding:

Welding mainly adopts advanced automatic welding, TIG welding. The drum and other main pressure parts are automatically welded by CNC, and all welding passes 100% X-ray inspection, and the welding process is subject to the inspection of the quality assurance department at any time.

Welding mainly adopts advanced automatic welding, TIG welding. The drum and other main pressure parts are automatically welded by CNC, and all welding passes 100% X-ray inspection, and the welding process is subject to the inspection of the quality assurance department at any time.

Market

:

Asia: China, Korea, Japan, Kazakhstan, Uzbekistan, Kyrgyzstan, Tajikistan, Azerbaijan, Singapore, Hongkong, Philippines,

Indonesia, Thailand, Myanmar, Laos, United Arab Emirates, Saudi Arabia, Palestine, Afghanistan, Bangladesh, Malaysia, Qatar, Lebanon, Armenia, Yemen, Jordan, Taiwan, Turkey, Iran

America: Colombia, Chile, Suriname, Peru, Bolivia, Ecuador, United States, Canada, Mexico, Uruguay, Argentina

Africa: South Sudan, Cameroon, Algeria, Libya, Benin, Nigeria, Egypt, Ghana, Guinea, Mauritius, Kenya, Ethiopia, Cote- d'Ivoire, Tunisia, South Africa, north Sudan, Madagascar

Australia: Australia, New Zealand

Europe: Russia, Ukraine, Belarus, Serbia, Albania, Netherlands, Poland, Serbia, Sweden

Asia: China, Korea, Japan, Kazakhstan, Uzbekistan, Kyrgyzstan, Tajikistan, Azerbaijan, Singapore, Hongkong, Philippines,

Indonesia, Thailand, Myanmar, Laos, United Arab Emirates, Saudi Arabia, Palestine, Afghanistan, Bangladesh, Malaysia, Qatar, Lebanon, Armenia, Yemen, Jordan, Taiwan, Turkey, Iran

America: Colombia, Chile, Suriname, Peru, Bolivia, Ecuador, United States, Canada, Mexico, Uruguay, Argentina

Africa: South Sudan, Cameroon, Algeria, Libya, Benin, Nigeria, Egypt, Ghana, Guinea, Mauritius, Kenya, Ethiopia, Cote- d'Ivoire, Tunisia, South Africa, north Sudan, Madagascar

Australia: Australia, New Zealand

Europe: Russia, Ukraine, Belarus, Serbia, Albania, Netherlands, Poland, Serbia, Sweden

Our Main Product scope:

1.Fire tube series Horizontal oil/gas fired boilers (0.5-30T/H, 0.7-21MW)

2.Water tube series Horizontal Oil/gas fired boiler (4- 35T/H )

3.Vertical fire tube series Vertical Oil/gas fired boiler (0.1-2 T/H, 0.06-0.7MW )

4.Large drum chain grate new type water fire tube boilers (1-35T/H, 0.7-29MW)

5. Double drum chain grate series water tube biomass boilers (4-35T/H, 1.4-29MW)

6. Electric boiler boiler ( 10--50 T/H)

7.Oil/Gas fired thermal oil boiler

8.Coal fired thermal oil boiler heater

9. High/low pressure of various fuels,CFB Circulating Fluidized Bed boiler ( 35T--400T )

1.Fire tube series Horizontal oil/gas fired boilers (0.5-30T/H, 0.7-21MW)

2.Water tube series Horizontal Oil/gas fired boiler (4- 35T/H )

3.Vertical fire tube series Vertical Oil/gas fired boiler (0.1-2 T/H, 0.06-0.7MW )

4.Large drum chain grate new type water fire tube boilers (1-35T/H, 0.7-29MW)

5. Double drum chain grate series water tube biomass boilers (4-35T/H, 1.4-29MW)

6. Electric boiler boiler ( 10--50 T/H)

7.Oil/Gas fired thermal oil boiler

8.Coal fired thermal oil boiler heater

9. High/low pressure of various fuels,CFB Circulating Fluidized Bed boiler ( 35T--400T )

Hot Searches