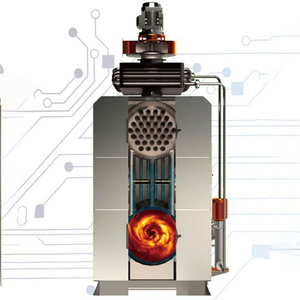

The working principle of coal/biomass steam

generator is to burn biomass particles/coal, produce heat energy after combustion, through the energy conversion, transfer heat

energy to the water in the tank, make the water temperature rise, make hot water vaporize to produce steam.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Depends on Boiler Capacity

-

Weight:

-

Depends on Boiler Capacity

-

Product name:

-

steam generator with control panel

-

Applicable Fuel:

-

Biomass; Coal

-

Steam Capacity:

-

60kg-500kg/h

-

Type of boiler:

-

Horizontal Steam Boiler

-

Operation:

-

Fully Automatic Control

-

Certificate:

-

CE ISO

-

Design pressure:

-

0.7 Mpa

-

Boiler Structure:

-

Firetube

-

Steam temperature:

-

151/170

-

Thermal efficiency:

-

92%

Quick Details

-

Core Components:

-

Other

-

Place of Origin:

-

China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

Depends on Boiler Capacity

-

Weight:

-

Depends on Boiler Capacity

-

Product name:

-

steam generator with control panel

-

Applicable Fuel:

-

Biomass; Coal

-

Steam Capacity:

-

60kg-500kg/h

-

Type of boiler:

-

Horizontal Steam Boiler

-

Operation:

-

Fully Automatic Control

-

Certificate:

-

CE ISO

-

Design pressure:

-

0.7 Mpa

-

Boiler Structure:

-

Firetube

-

Steam temperature:

-

151/170

-

Thermal efficiency:

-

92%

Products Description

Coal / Biomass Steam Generator

Product Paramenters

|

Model

|

|

Unit

|

LSG0.05-0.4

|

LSG0.1-0.4

|

LSG0.2-0.4

|

LSG0.3-0.7

|

LSG0.5-0.7

|

LSG0.7-0.7

|

LSG1-0.7

|

|||||||

|

Rated steam capacity

|

|

KG/H

|

50

|

100

|

200

|

300

|

500

|

700

|

1000

|

|||||||

|

Rated steam pressure

|

|

Mpa

|

0.4/0.7

|

0.4/0.7

|

0.4/0.7

|

0.4/0.7

|

0.4/0.7/1.0

|

|

|

|||||||

|

Steam temperature

|

|

℃

|

151/171

|

|

|

151/171/184

|

|

|

|

|||||||

|

Feed water temperature

|

|

℃

|

20

|

|

|

|

|

|

|

|||||||

|

Thermal efficiency

|

|

%

|

≥86

|

|

|

|

|

|

|

|||||||

|

Applicable energy

|

|

|

Biomass / Coal / Firewood

|

|

|

|

|

|

|

|||||||

|

Voltage

|

|

V

|

220

|

|

|

|

|

|

|

|||||||

|

fuel consumption

|

Biomass

|

KG/H

|

10

|

20

|

35

|

56

|

95

|

134

|

185

|

|||||||

|

|

Coal

|

KG/H

|

8

|

15

|

31

|

46

|

77

|

108

|

153

|

|||||||

|

|

firewood

|

KG/H

|

13

|

23

|

42

|

63

|

115

|

142

|

210

|

|||||||

Details Images

1. . Environmentally friendly operation, fuel saving, automatic feeding and slag discharge, frequency conversion adjustment of blower induced draft fan, fully automatic operation of boiler, automatic adjustment of fuel amount according to load changes, and stable

steam output.

steam output.

2. It has a number of protection and alarm measures such as pressure, water level and exhaust gas temperature to ensure the safe operation of the boiler.

3. Compared with the old vertical boiler, this boiler has a large heating area, fast temperature rise and pressure increase, less biomass consumption, high thermal efficiency, and can save biomass by 25-30%.

Hot Searches