- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

6500*1500*1500mm

-

Weight:

-

5000 kg

-

Frame Design:

-

iron cast/steel plate

-

Roll Stages:

-

14-16 Stages

-

Shafts Diameter:

-

70mm

-

Main Motor Power:

-

5.5kw

-

Hydraulic Power:

-

4kw

-

Material of Cutting Blade:

-

Cr12, Heat Treatment

-

Control System:

-

PLC

-

Machine Structure:

-

350h Steel Welding

-

Product Type:

-

Corrugated Roofing Sheet

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

6500*1500*1500mm

-

Weight:

-

5000 kg

-

Frame Design:

-

iron cast/steel plate

-

Roll Stages:

-

14-16 Stages

-

Shafts Diameter:

-

70mm

-

Main Motor Power:

-

5.5kw

-

Hydraulic Power:

-

4kw

-

Material of Cutting Blade:

-

Cr12, Heat Treatment

-

Control System:

-

PLC

-

Machine Structure:

-

350h Steel Welding

-

Product Type:

-

Corrugated Roofing Sheet

Product Certification

CE Certified.Valid from 2020-07-18 until 2025-07-18

Packaging & Delivery

Selling Units: Single item

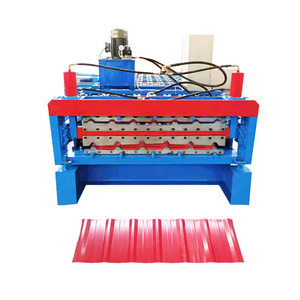

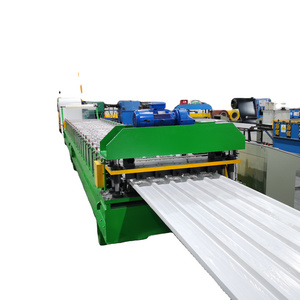

GI PPGI trapozoid roof tile IBR color steel metal roof sheet making machinary cold roll forming machine with high quality

Our hot sell 1000 trapezoidal roofing sheet metal ibr roof sheeting wall panel long span IBR roll forming machine for different models based on different designs or customer's samples.It is a machine to produce building material of metal roof, the products are widely used as the roof and wall of factory,warehouse, garage, gymnasium, exhibition center.It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.Our offering includes a wide product range ,from economical solutions to structural sheets with deep corrugations, with parameters suitable for use in the most demanding industrial applications. The products come in a wide range of colours and coatings, cut to individual requirements.All box profile sheet types can be covered with an anti condensation coating. Trapezoidal sheets can also be perforated.

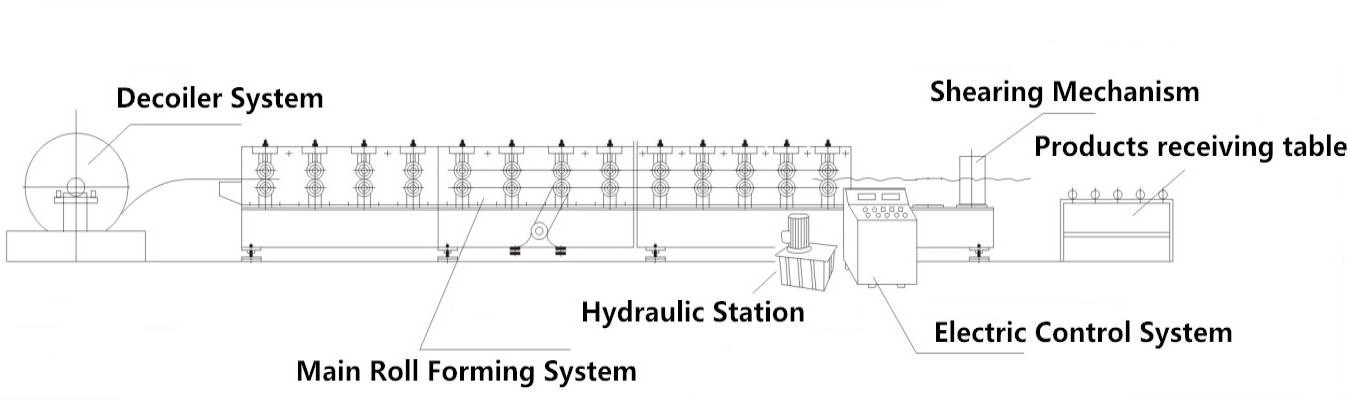

Work flow of production line

Decoiler:

( Selectable configuration ):

1) Left ( Standard configuration ): Manual simple decoiler;

2) Right (Optional configuration ): Hydraulic decoiler;

3) Loading Lecel: 5tons(common), 8tons, 10tons, 15tons or as requirement;

4) Loading Width: Max. 1250mm or 1450mm (common);

5) Loading Inner Diameter: φ450-550mm;

6) Loading Outer Diameter: Max. φ1500mm

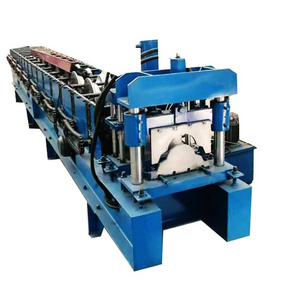

Main Roll Forming Machine:

1) Driving Type: Chain(common) or Gear or Gearbox;

2) Forming Model: Integral Forming or Split Forming;

3) Forming Machine structure: Medium-plate Type(common) or Arch Type or Guide-pillar type;

4) Roller: 45# or Cr12 or GCr15 or GCr12MoV

5) Shaft: 45# or 40Cr; 70mm/80mm/90mm(common) or as design;

6) Motor Power: 4.0kW or 5.5kW or according to the design requirements;

7) Main Frame: 350# or 400# H-beam steel welded.

Cutter:

1) Working Model: Hydraulic Cutter (common) or Electric Cutter;

2) Cast iron tool holder: obvious shock absorption effect and strong impact resistance.

3) Cutter Blade Material: Cr12.

The cutting life exceeds 1 million times.

4) Rear scissor frame: Q235 steel plate, annealing treatment after rough turning, finishing

Collecting Product Table

1) Left: Automatic Stacker (optional configuration)--Length: According to customized;

2) Right: Manual Simple collecting product table (standard configuration)--Length: 3m(common) or as customized.

PLC control cabinet:

1) PLC:Adopt DELTA high-precision PLC electronic device.

2) Inverter:DELTA Heavy-duty inverter,running efficienty and stable.

3) Control components: with long service life and low failure rate.

4)Touch screen control:input production data and automatically complete production requirements.

Product Features

1. More efficient and accurate execution of production orders

;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

Application of the finished product: