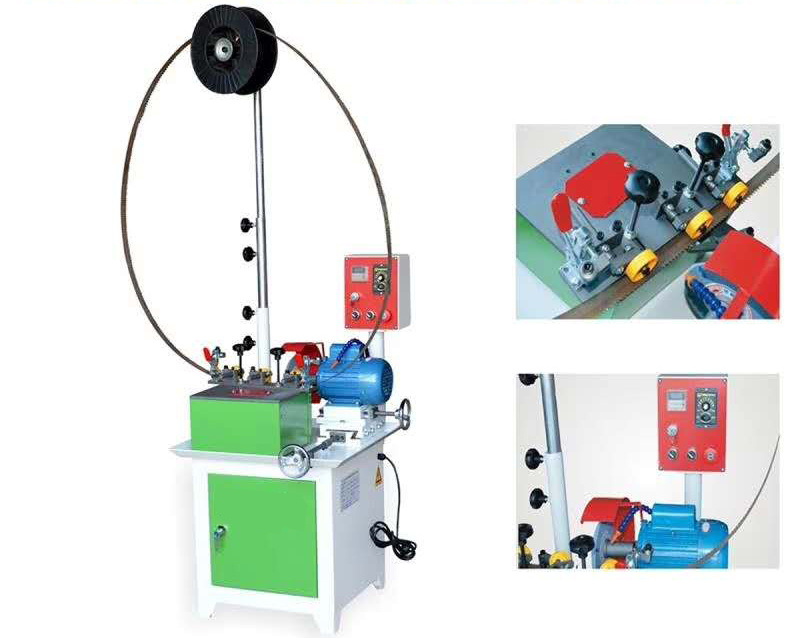

Ideal for simple, quick and accurate sharpening of bandsaw blades for the sawing of logs; careful maintenance of the saw blades is actually a determining factor to achieve the best possible results during sawing.

The band saw blade sharpener machine has been designed to sharpen blades with regular carbide tips.

There are different interchangeable feed speeds depending on the type of tooth and on the accuracy of sharpening wanted.

through which all adjustments can be performed.

limit switch prevents the feed of the blade if the grinding wheel is lowered without starting rotation