- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

8 - 30

-

Marketing Type:

-

New Product 2022

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

HONG KY

-

Voltage:

-

380V/50HZ

-

Rated Power:

-

220kw

-

Dimension(L*W*H):

-

23 m x 13 m x 2 m

-

Weight:

-

80000

-

Year:

-

2022

-

Material:

-

HRC, CRC, Galvanized steel, stainless steel

-

Input Coil Width:

-

600 mm - 1350 mm

-

Coil Outer Diameter:

-

1000 mm - 1800 mm

-

Coil Inner Diameter:

-

Entry coil: 508/610mm; Exit coil: 508 mm

-

Coil Thickness:

-

0.5 - 3.2 mm

-

Min width of slitting strip:

-

30 mm

-

Speed:

-

80-160m/min

-

Slit width tolerance:

-

±0.1mm

-

Slit edge bur:

-

<=3% of coil thickness

-

After-sell service:

-

on site installation and training

Quick Details

-

Cutting Width (mm):

-

30 - 1350 mm

-

Material Thickness(mm):

-

0.5 - 3.2 mm

-

Cutting Speed(m/min):

-

20 - 160 mm

-

No. of Slitting Lines:

-

8 - 30

-

Marketing Type:

-

New Product 2022

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

Ho Chi Minh City, Vietnam

-

Brand Name:

-

HONG KY

-

Voltage:

-

380V/50HZ

-

Rated Power:

-

220kw

-

Dimension(L*W*H):

-

23 m x 13 m x 2 m

-

Weight:

-

80000

-

Year:

-

2022

-

Material:

-

HRC, CRC, Galvanized steel, stainless steel

-

Input Coil Width:

-

600 mm - 1350 mm

-

Coil Outer Diameter:

-

1000 mm - 1800 mm

-

Coil Inner Diameter:

-

Entry coil: 508/610mm; Exit coil: 508 mm

-

Coil Thickness:

-

0.5 - 3.2 mm

-

Min width of slitting strip:

-

30 mm

-

Speed:

-

80-160m/min

-

Slit width tolerance:

-

±0.1mm

-

Slit edge bur:

-

<=3% of coil thickness

-

After-sell service:

-

on site installation and training

Product Description

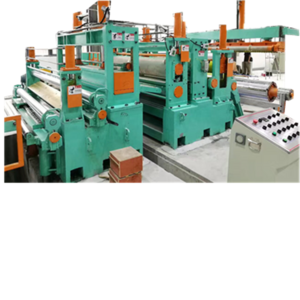

HONG KY high speed steel coil slitting line model is designed to divide the big coil steel into smaller coils based on required dimension of slitting trips. This machine is used in the manufacturing factories of wide range of products such as steel pipes, home appliances, furniture, car components etc. It can cut these materials such as galvanized steel, hot roll steel,

cold roll steel, and stainless steel.

HONG KY high speed steel coil slitting line was designed and made by the Japanese Expert. With more than 35 years in mechanical engineering and the experienced research and design team, Hong Ky commits to provide our clients the full packaged services including consultancy, design, manufacture, installation, warranty, and maintenance.

The unique selling point of Hong Ky is stability, durability to contribute to improving the working efficiency.

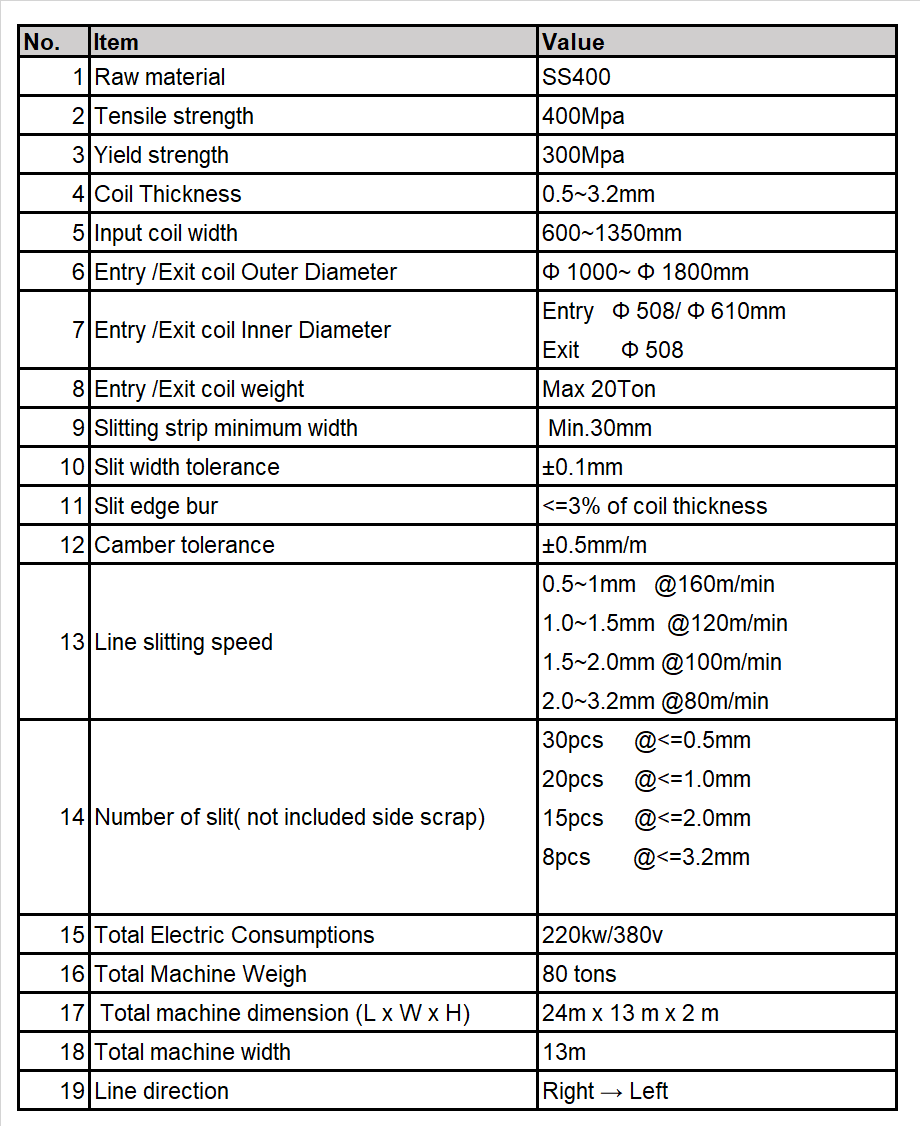

Specification

Our Advantages

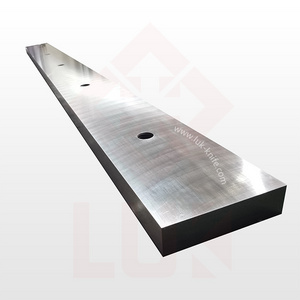

* Thanks to the double slitting system, quick adjusting the clearance of knife blade has achieved.

* It is efficient because a knife blade set can be done outside the line.

* It has become possible to experimentally cut outside the line.

* Since all hydraulic piping and electrical wiring are buried underground, the ground is clean and easy to walk.

2. Gear Box

* Hong Ky Slitting line has 3 Gear box (Reducer). All gear boxes are designed and manufactured by Hong Ky , then the design became compact and efficient.

3. Scrap disposal

* It is unique design. It is automatic drop down.

* After winding the scrap, the scrap is automatically dropped on the conveyor, and the scrap is conveyed to the scrap box.

4. Latest advanced mandrel shaft of Tension Reel.

* Hong Ky have adopted one of the advanced and latest Mandrel Shafts Mechanism. The mandrel shaft is designed to minimize the amount of bending when pinching the edge of the metal sheet.

5. Line Design

* Line design is a crystal of technology that the steel industry has built over several decades.

* It is economic, reasonable, long life, and strong design.

6. Product liability

* The safety Measurment is taken into consideration in order to meet the product liability law.

* The moving parts are covered as much as possible.

Hot Searches