- Product Details

- {{item.text}}

Quick Details

-

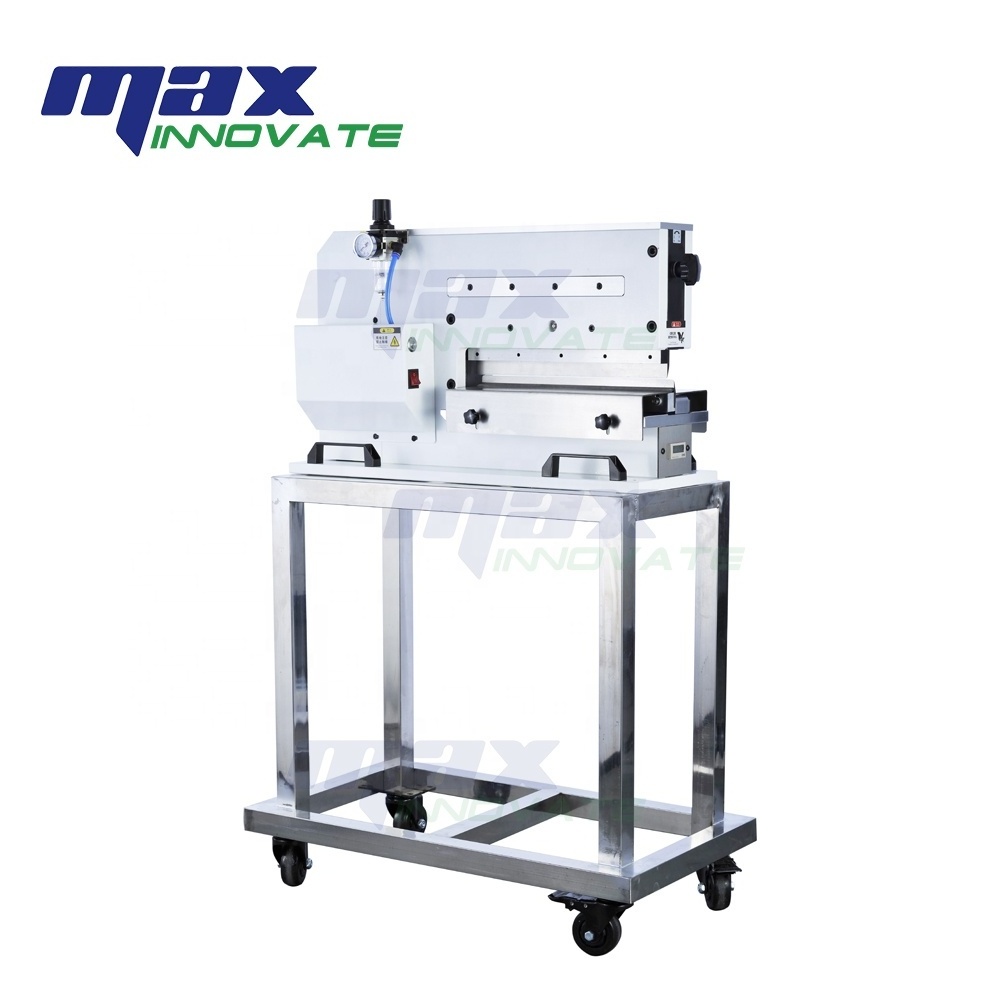

Model Number:

-

MAX-310

-

Dimensions:

-

325*380*340mm

-

source:

-

220V/50Hz(110V/60Hz)

-

Power supply:

-

60W

-

Splitting thickness:

-

0.8-3.0mm

Quick Details

-

Weight (KG):

-

49

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Max-innovate

-

Model Number:

-

MAX-310

-

Dimensions:

-

325*380*340mm

-

source:

-

220V/50Hz(110V/60Hz)

-

Power supply:

-

60W

-

Splitting thickness:

-

0.8-3.0mm

Product Description

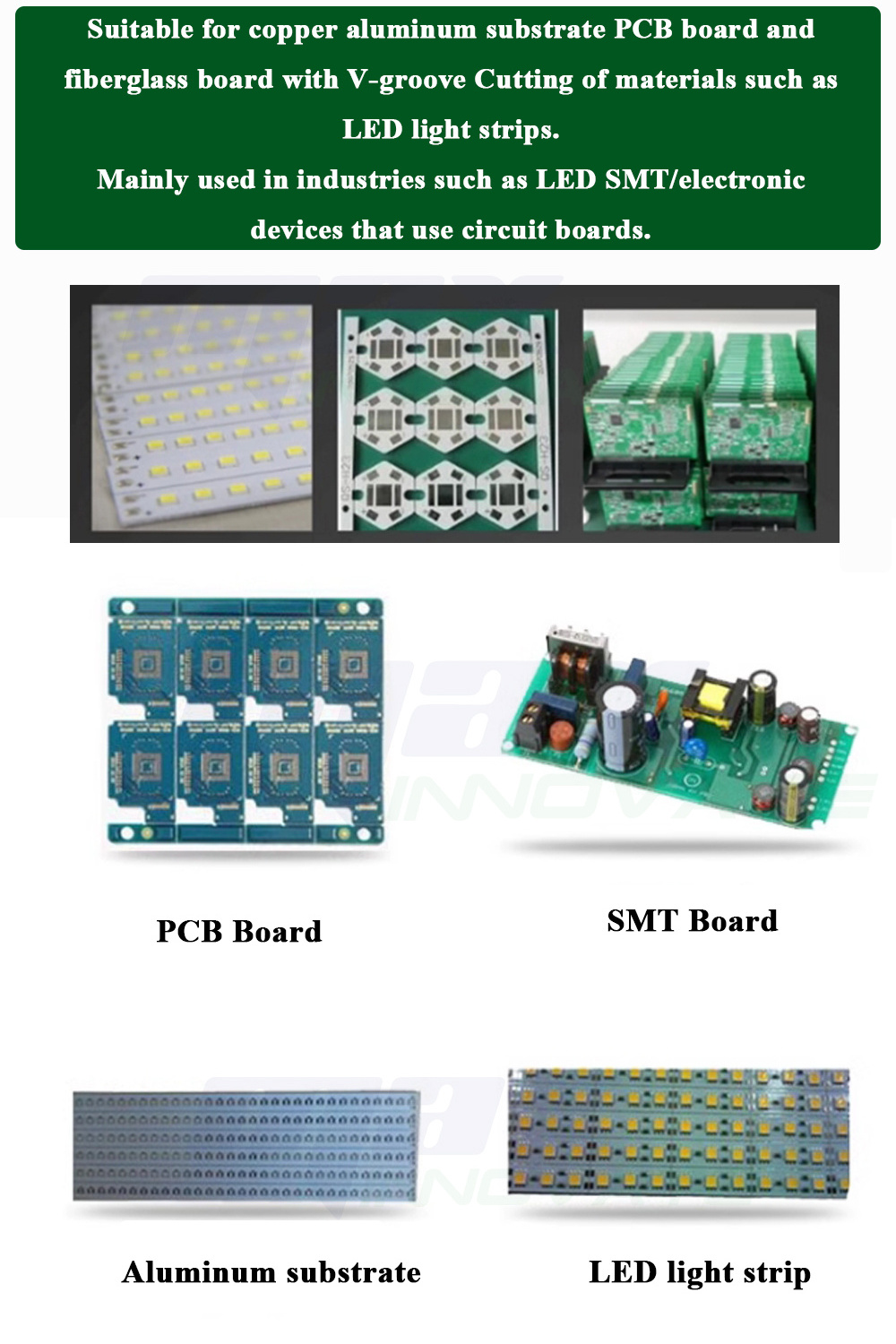

Features:

3. All cutting blades are calibrated using an excitation dual frequency laser interferometer to ensure that the rear blade can accurately continue cutting in the groove cut by the front blade. The jumping of the blade tip should not exceed 0.02mm to ensure perfect cutting quality.

4. Stainless steel platform with laser scale positioning function (1.2m or 2.4m optional)

|

Model

|

MAX-310

|

|

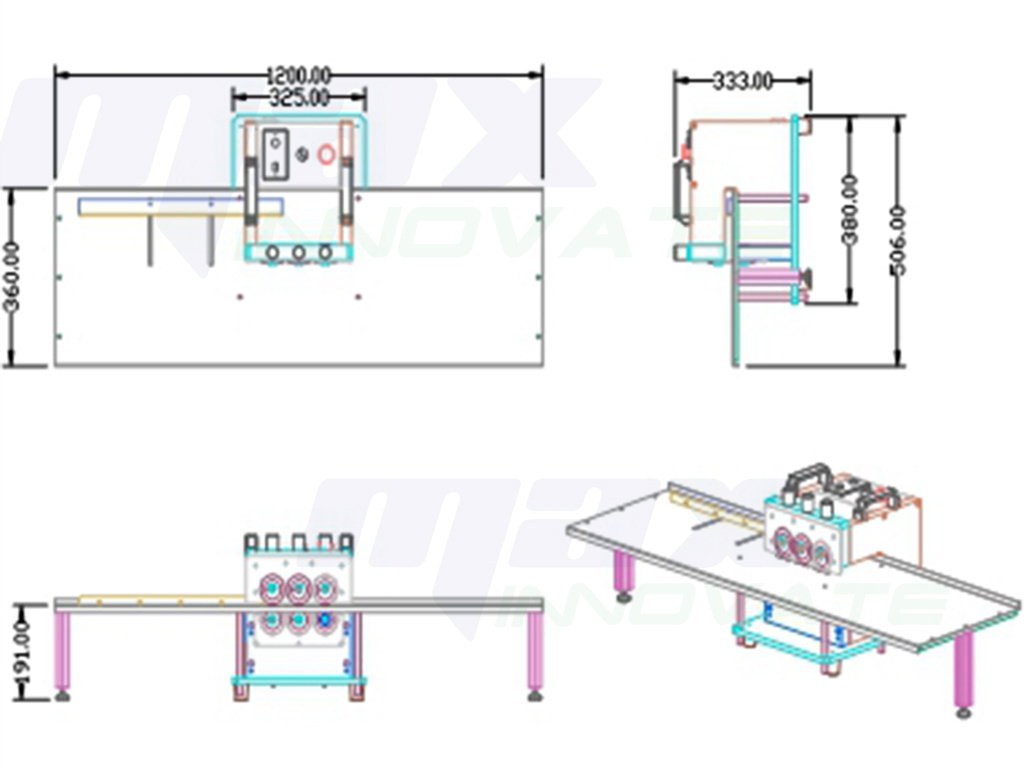

Host Dimension

|

325*380*340mm

|

|

Platform dimension

|

1200 x 360x190mm(1.2M)

2400 x 360 x 190mm(2.4M)

|

|

Blade material

|

SKD61 high-speed steel

|

|

Splitting thickness

|

0.8-3mm

|

|

power

|

60W

|

|

Splitting

speed

|

80, 120, 200, 400mm/s

|

|

Maximum Splitting Length

|

Unlimited

|

|

Weight

|

1.2M—41KG

2.4M—49KG

|

Details

Related Products

You can choose these related products for your SMT & DIP line.

Welcome contact with us !

Packing & Delivery

Packing details:

Plywood case for export

Port:Shenzhen

Delivery Time:7—15 days

Hot Searches