- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

13000

-

Power (kW):

-

7.5

-

Name:

-

Automatic 3D Fence Panel Mesh Welding Machine

-

Wire diameter:

-

2.5-6mm

-

welding aperture:

-

50*50-200*200mm

-

max width:

-

2500mm

-

welding power:

-

125KVA*8

-

number of electrodes:

-

51

-

welding speed:

-

60-70times/min

Quick Details

-

Wire Diameter (mm):

-

3 - 6 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Feiteng

-

Weight (KG):

-

13000

-

Power (kW):

-

7.5

-

Name:

-

Automatic 3D Fence Panel Mesh Welding Machine

-

Wire diameter:

-

2.5-6mm

-

welding aperture:

-

50*50-200*200mm

-

max width:

-

2500mm

-

welding power:

-

125KVA*8

-

number of electrodes:

-

51

-

welding speed:

-

60-70times/min

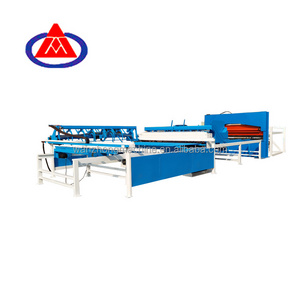

Automatic 3D Fence Panel Mesh Welding Machine

The machine adopts synchronous control technique, both welding time and cent-control welding is composed of PLC program system.

The input front-panel has two forms, touch screen and keyboard, it makes the machine more intelligent and reasonable.

The weft wire supply is automatic.

The greatest advantage is that it can be adjusted the distance of weft random on the same one piece of mesh sheet.

Welding machine adopts new type high-efficiency transformer, shifting gear can be divided into eight level, expand the scope of welding wire diameter.

Easily operation, high flexibility, the production is several times than the artificial single spot welding machine.

It mainly used for fence netting (highway, railway and mountain fence mesh, construction mesh etc.)

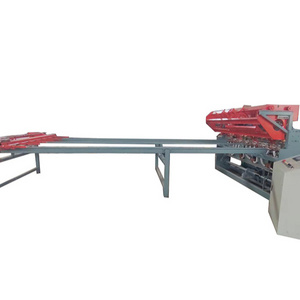

| Cross wire diameter | 2.5-6mm |

| Line wire diameter | 3-6mm |

| Width of mesh | ≤2500mm |

| Line wire spacing | 300≥X≥50mm mechanical adjustment |

| Cross wire spacing | ≥50mm freely programming adjustment |

| L ine wire feeding method | pre-cut/feeding by hand |

| Cross wire feeding method | pre-cut/auto feeding |

| Number of max.welding spot | 51 pcs/row |

| Welding speed | 60-70times/min |

| Control method | PLC programming control, servo stepper system |

| Main power | 5.5 kw(inverter braking) |

| Transformer power | 160KVA*6 |

| Rated frequency | 50HZ(can be customized to the practical environment ) |

| Supply voltage | 380V(can be customized to the practical environment) |

| Weight | 6.5T |

| Overall dimension | 15000*6000*2600mm |

1. Control system: intelligent PLC(Mitsubishi or Panasonic)

2. Touch screen: Weinview (Taiwan)

3. Low-voltage apparatus: Schneider

4. Pneumatic components: Japan SMC, more stable

5. Cross wire feeding step hopper: equipped with feeding car

6. Mesh pulling: servo motor (Mitsubishi or Panasonic)

7. Line guide way: TBI(Taiwan ) or HIWIN(Taiwan)Parameter

Packaging Details: Plastic bag or at customers' request.

Delivery Time: Shipped in 45 days after payment.

Pre-sale service

1. Select equipment model.

2. Design and manufacture products according to clients' special requirement.

Services during the sale

1. Pre-check and accept products ahead of delivery.

2. Help clients to draft solving plans.

After-sale service

1. We will reply you for your inquiry in 24 hours.

2.

After you get the products, we'll send technicians to your factory. Then they will guide your workers to install and debug the machine patiently untill the machine can work normally. Since our factory established, our after-sale team had been to many contries and received customers' critical acclaim.