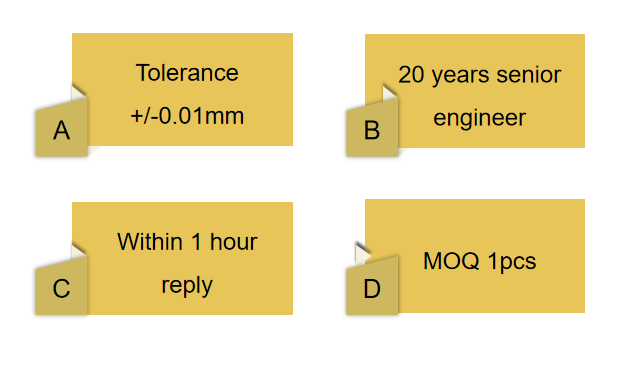

We have the professional engineer teams with technology and experiences in engineering plastic industry for more than

15 years

! Our company is located in Haicang District,Xiamen City, China, where the logistics is developed!

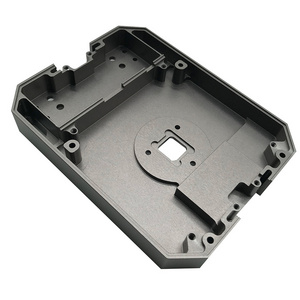

With the rich experiences and technology for manufacture, design,research and development ability, support personalized customization. There are full set of high efficiency producing equipment and advanced numerical control machines,such as: molding injection machines, CNC molding manufacture machines, fine carving machines,Horizontal lathes, milling machines. That can customize all kinds of Engineering plastics products according to our customers’drawings or samples.