- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Taiwan

-

Pressure:

-

250bar

-

Structure:

-

hydraulic

-

Weight:

-

21

-

Power:

-

n/a

-

Dimension(L*W*H):

-

10x20x15

-

Maximum pressure:

-

250bar

-

Maximum Flow Rate:

-

500l/min

-

port size 10:

-

1-1/4"

-

Body material:

-

Cast Steel

-

Pressure Adj Range:

-

7-70 kgf/cm2

-

Max Pressure:

-

250 kgf/cm2

-

Max Flow:

-

500 liter/min

-

Bolt Size:

-

M20*160*4pcs

Quick Details

-

Warranty:

-

1 year

-

Valve type:

-

Pressure control valve

-

Brand Name:

-

LCH

-

Place of Origin:

-

Taiwan

-

Pressure:

-

250bar

-

Structure:

-

hydraulic

-

Weight:

-

21

-

Power:

-

n/a

-

Dimension(L*W*H):

-

10x20x15

-

Maximum pressure:

-

250bar

-

Maximum Flow Rate:

-

500l/min

-

port size 10:

-

1-1/4"

-

Body material:

-

Cast Steel

-

Pressure Adj Range:

-

7-70 kgf/cm2

-

Max Pressure:

-

250 kgf/cm2

-

Max Flow:

-

500 liter/min

-

Bolt Size:

-

M20*160*4pcs

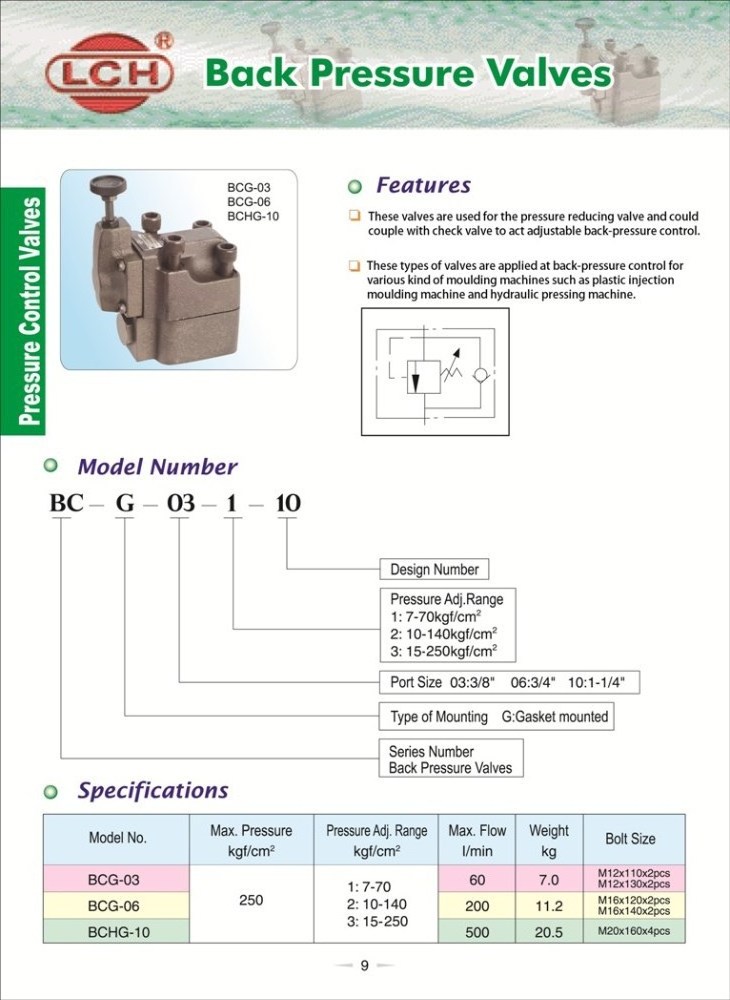

LCH BCHG-10-1 Back Pressure Valves

Features:

- These valves are used for the pressure reducing valve and could couple with check valve to act adjustable back-pressure control.

- These types of valves are applied at back-pressure control for plastic injection molding machine & hydraulic pressing machine ect.

pecifications:

|

Model Numbers |

Max. Pressure |

Pressure Adj. Range |

Max. Flow |

Weight |

Bolt Size |

|

kgf/cm 2 |

kgf/cm 2 |

l/min |

kg |

BSG- |

|

|

BCG-03 |

250 |

1: 7-70, 2:10-140, 3:15-210 |

60 |

1.0 |

M12x110x2pcs |

|

BCG-06 |

|

200 |

11.2 |

M16x120x2pcs |

|

|

BCHG-10 |

|

500 |

20.5 |

M20x160x4pcs |

Model Number:

|

BCH |

G |

10 |

1 |

10 |

|

l |

l |

l |

l |

l |

|

Series Number Back Pressure Valves |

Type of Mounting G: Gasket type |

Port Size 10:1-1/4” |

Pressure Adj. Rang 1:7-70kgf/cm 2 2:10-140kgf/cm 2 3.:15-210kgf/cm 2 |

Design Number |

Model Number: BCHG-10-1

How to order:

|

|

Model code |

Descriptions |

|

1- |

BCH |

Series Number Back Pressure Valves |

|

2- |

G |

Type of Mounting G: Gasket type |

|

3- |

10 |

Port Size

10:1-1/4” |

|

4- |

1 |

Pressure Adj. Range 1:7-70kgf/cm 2 2:10-140kgf/cm 2 3:15-250kgf/cm 2 |

|

5- |

10 |

Design Number |

With customers from more than 40 different countries shows that the professional technical team, manufacturing team and post-sale team of Lih Cherng Hydraulic (LCH) brings customer's satisfaction.

LCH offers:

1. small order (MOQ 1pc) service

2. after-sales service (through videos, phone call, video conference)

3. Proof of customers satisfaction over 40 different countries who are using LCH hydraulic components

4. Product and system support within 3 hours quickly response service

24-hour helpdesk

with expert support around the clock. Are you tired of limited responses from Chatbots customer support? hydraulic industry is definitely not a business can use Chatbots to offer customer support.

LCH offers helpdesk experts who could be reached via what's app, skype, or wechat app when you are facing any difficulty of hydraulic system. Efficient communication is achieved by having project-specific documentation in place.

5. Batch production & Spare inventory

Batch production way is used in LCH, so inventory quantity is available for customers and part-finished goods are ready to be assembled and shipped anytime.LCH makes sure the inventory quantity available for all period, so customers could always obtain the components in no time.

6. Good packaging

Are you tired of receiving the order damaged du e to poor packaging?

LCH packs each piece with a poly plastic bag in a industrial heavy-duty cartons with proper cushions minimizing damage, strapping on carton and wrapping the carton with film to ensure our customers receiving their orders with peace of minds

7. Quality Control

100% strictly quality control on each hydraulic components (simple random sampling is not acceptable) Material, dimensional, weight, pressure, flow rate are tested before package

Product applications:

Hydraulic components such as hydraulic valve, solenoid valve, hydraulic directional valve, oil pump, hydraulic gear pump, gear pump, electric motor, electrical motor, ac motor, hydraulic cylinder, cylinder, hydraulic power pack, hydraulic power unit, hydraulic power station, sandwich check valve, flow control valve, hydraulic pump and chemical pump are able to used in injection molding machine, automatic compacting press, die casting machine, hydraulic excavator, garbage truck, machine center, and rubber press machines .