- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

STANDARD

-

Weight:

-

50000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220/380 or customized

-

Power:

-

150KW

-

Application:

-

Fruit

-

Name:

-

paste production line

-

Function:

-

Multifunctional

-

Product name:

-

1000 paste production line

-

Feature:

-

High Efficiency

-

Usage:

-

Commercial Usage

-

Material:

-

304 Stainless Steel

-

Item:

-

Automaticpaste production line r Machine

-

Capacity:

-

5T/h

-

Applicable Industries:

-

Food & Beverage Factory

Quick Details

-

Machinery Capacity:

-

customized

-

Brand Name:

-

genyond

-

Year:

-

2019

-

Dimension(L*W*H):

-

STANDARD

-

Weight:

-

50000 KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

220/380 or customized

-

Power:

-

150KW

-

Application:

-

Fruit

-

Name:

-

paste production line

-

Function:

-

Multifunctional

-

Product name:

-

1000 paste production line

-

Feature:

-

High Efficiency

-

Usage:

-

Commercial Usage

-

Material:

-

304 Stainless Steel

-

Item:

-

Automaticpaste production line r Machine

-

Capacity:

-

5T/h

-

Applicable Industries:

-

Food & Beverage Factory

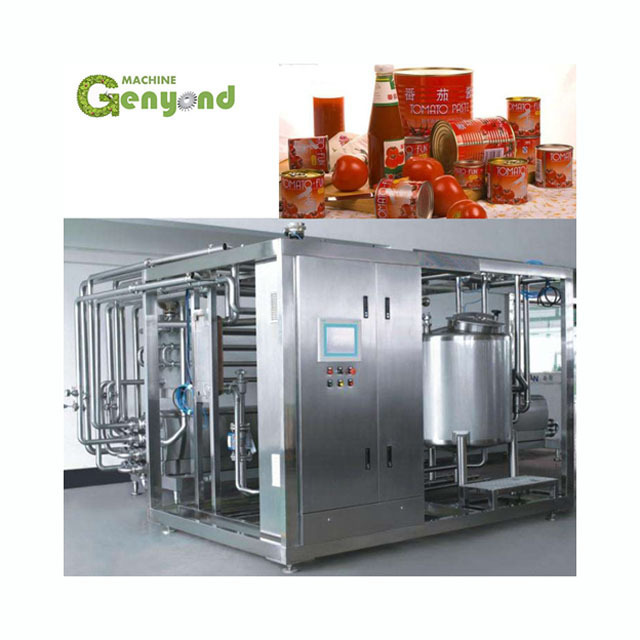

Tomato ketchup sauce paste production line

Lifting system, cleaning system, sorting system, crushing system, preheating enzyme sterilization system, beating system, vacuum concentration system, sterilization system and aseptic bag filling system, including lifting system, cleaning system, sorting system, crushing system , Preheating enzyme system, beating system, vacuum concentration system, sterilization system and aseptic bag filling system.Production capacity includes: 150 tons of raw materials (fresh tomatoes, peppers, apples, strawberries, blackberries, carrots, onions, etc.), 300 tons, 400 tons, 500 tons, 600 tons, 800 tons, 1000 tons, 1200 tons, 1500 tons.

The whole line can process concentrated fruit and vegetable products such as strawberry jam, blackberry jam, blueberry jam, raspberry jam, apple jam, mango jam, apricot jam, carrot jam, onion jam and chili jam.

|

Processing Capacity

(fresh fruit) |

60

|

150

|

250

|

500

|

750

|

1000

|

1250

|

1500

|

|||||||

|

Water Consumption

(t/h) |

7

|

13

|

22

|

44

|

66

|

88

|

110

|

132

|

|||||||

|

Power

(kw) |

84

|

152

|

412

|

636

|

955

|

1292

|

1411

|

1558

|

|||||||

|

Steam Consumption

(t/h) |

1.7

|

3.9

|

5.2

|

9.1

|

15.1

|

20.2

|

24.6

|

29.2

|

|||||||

|

Compressed Air Consumption (t/h)

|

66.2

|

66.2

|

66.2

|

72.2

|

72.2

|

72.2

|

72.2

|

72.2

|

|||||||

|

Cooling Water Consumption (t/h)

|

125

|

317

|

407

|

585

|

825

|

1075

|

1410

|

1630

|

|||||||

|

Advantages:

|

The tomato processing line from Shanghai Gofun machinery company is running with high effective, water saving, high extracting

rate, safety quality control for final product, safety control for operators, etc. |

|

|

|

|

|

|

|

|||||||

Specifications

Packing lines can be offered depending upon the requirement like Product in glass bottles, Cans, Drums, etc. Manufacturing process involves most modern technology of vacuum evaporation using forced circulation evaporators/scrapped surface evaporators. Evaporation plants are versatile in nature and can concentrate other juices also.

Features and benefits

Our range of technologically advanced tomato processing solutions is designed to minimize downtime and maximize operational efficiency while respecting the highest safety standards and improving the quality of final products.

We are committed to providing targeted solutions, optimizing the functions of your production line and ensuring that your products and processes surpass competitors. Our extensive collection of tomato processing equipment ensures that:

High quality juice preparation - beyond's advanced enzyme treatment method produces tomato juice that meets the highest quality and taste standards.

Advanced paste production - our state-of-the-art evaporator is designed to consistently improve paste quality by reducing holding time, maintaining low temperature, improving circulation speed and reducing water and steam consumption.

Excellent paste sterilization - beyond sterile flash cooler is designed according to strict technical standards. This ensures

better color, higher concentration consistency, lower energy consumption, less maintenance, longer operation time, and higher flexibility and customization.

Efficient evaporation - all beyond evaporators are designed to produce the highest quality ketchup on the market and maintain the sensory characteristics of fresh fruit; Multi effect design can also save energy and reduce operating costs.

The most advanced fruit juice refining technology - our variable speed turbine Juicer professionally separates tomato skin and seeds from fruit pulp to extract and refine fruit juice; The juicer can adjust the juice level in the process of juices.

Advanced aseptic filling machine - beyond's various single head and double head filling machines can choose to fill different types of aseptic bags.

Customizable and intuitive control system - our control system provides the most advanced support network and formula driven touch screen interface in the market; The system allows the processor to remotely control its devices and access beyond support directly from smart devices.

Professional after-sales technical support - in addition to the top machines we develop, we also provide comprehensive after-sales support, including technical services and spare parts.

Excellent processing and excellent product quality

Our range of tomato processing equipment is designed to maximize efficiency, yield and convenience while minimizing unnecessary energy, time and money expenditures. Our solutions achieve these specific goals without sacrificing any aspect of the final product quality. The juice, jam or puree you produce using our technology and equipment will meet the highest standards of appearance, taste and freshness.

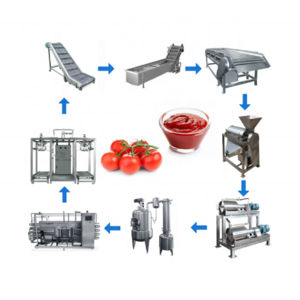

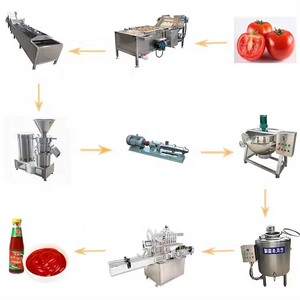

Production line machine composition:

fruit collecting and feeding;

tomato washing machine;

tomato sorting machine;

cold break tomato pulping machine;

tomato puree storage tank;

tubular tomato pre-heating machine ;

tomato refining machine;

tomato paste/sauce/ketchup evaporator;

tomato paste/ sauce/ketchup storage tank;

tomato paste/ sauce/ketchup sterilizer;

tomato paste/ sauce/ketchup aseptic filling machine.

Raw material : Fresh Tomato

Final product : Tomato paste ( Concentration : 28~30%) / ( 30%~32%)/ ( 36~38% )

Handing capacity : 10-1500T / day

Paste content : Pure flavors, vitamins, sugar and other flavors.

Sterlization way : High temperature , Tubular sterilization , UHT High temp Sterilization , Ultra high temperature sterilization( We will designa ccording to customser 's requirement )

Final package : Aseptic buckets, small bags of bags in bags, tinplate and small bags.

Cotrol system : Manual control or automatic control can be used in two ways below 300 tons.

System Content : The original fruit lifting system, cleaning system, sorting system, crushing system, preheating and killing enzyme system, beating system, vacuum concentrating system, dispensing system, sterilization system, sterile large bag filling system, small packaging and packing system.