- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YuFeng

-

Weight:

-

5000 KG

-

Product name:

-

Bottle Filling Capping

-

Function:

-

Washing Filling Capping

-

Usage:

-

Filling Capping Labeling Packaging

-

Advantage:

-

Efficiency

-

Suitable for:

-

Liquid Food

-

After Warranty Service:

-

Engineers

-

Bottle type:

-

Aluminum Can

-

Filling Liquid:

-

Beer

-

Operation:

-

Automatic Operation

-

Keywords:

-

Fillng Machine

-

Marketing Type:

-

Hot Product 2022

Quick Details

-

Machinery Capacity:

-

8000BPH

-

Packaging Material:

-

Metal

-

Filling Material:

-

Beer

-

Filling Accuracy:

-

±1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YuFeng

-

Weight:

-

5000 KG

-

Product name:

-

Bottle Filling Capping

-

Function:

-

Washing Filling Capping

-

Usage:

-

Filling Capping Labeling Packaging

-

Advantage:

-

Efficiency

-

Suitable for:

-

Liquid Food

-

After Warranty Service:

-

Engineers

-

Bottle type:

-

Aluminum Can

-

Filling Liquid:

-

Beer

-

Operation:

-

Automatic Operation

-

Keywords:

-

Fillng Machine

-

Marketing Type:

-

Hot Product 2022

Video Description

Product Description

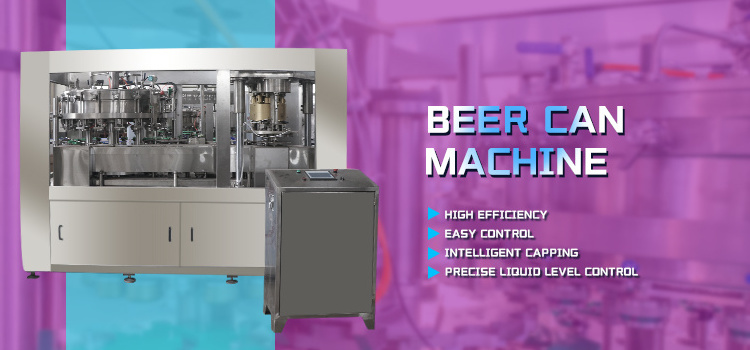

The main transmission adopts gear transmission belt and gear box type exposed drive combination with advantages of higher efficiency, lower noise and smoother operation. It adopts frequency conversion stable speed regulation and is controlled by PLC

industrial computers. Sealing machine and filling machine are connected by hooks coupling universal coupling to make sure they’re at same working pace. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Germany's Danfoss, France Schneider, OMRON or ABB.

industrial computers. Sealing machine and filling machine are connected by hooks coupling universal coupling to make sure they’re at same working pace. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Germany's Danfoss, France Schneider, OMRON or ABB.

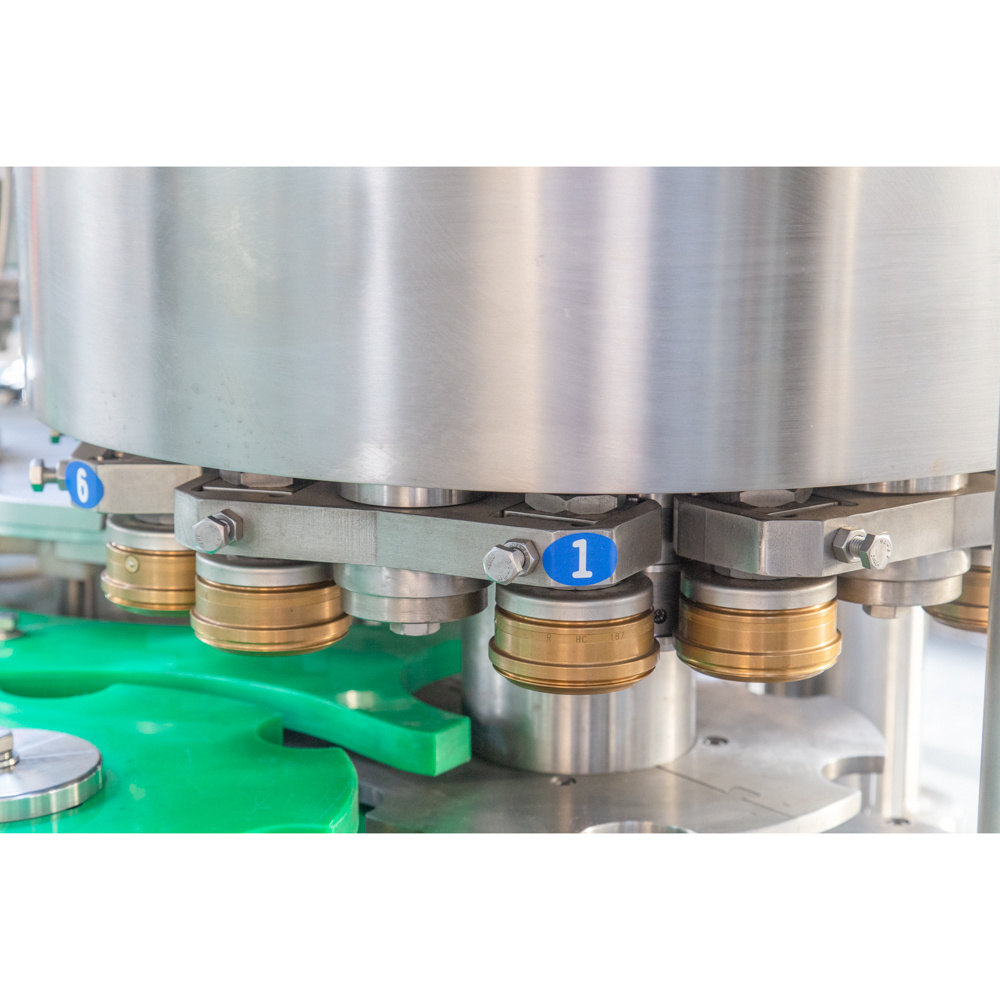

Details Images

Beer canning machine, aluminum can

This Beer canning Machine canning-seaming 2-in-1unit is used to produce aluminum canned beer. It can finish all the process such as beer canning and sealing, it can reduce the materials and Outsiders touch time, improve the sanitary conditions, production capacity and economic efficiency. It’s design combines with the actual situation in our country after the introduction and absorption from foreign developed technology.

It adopts isobaric filling principle and filling valve adopts high precision mechanical valve. It has advantages of fast filling

speed, high precision in liquid level and ensure that it only starts to filling when there is a can, otherwise it will stop. Using

the device structure of filling valve precover device plus supporting can bottom device, it can guarantee the maximum stability of cans when they passing in and out. Filling cylinder braces use worm-gear box going up and down to satisfy cans of different height. Float switches in the filling cylinder ensure a smooth liquid inlet state.

It adopts isobaric filling principle and filling valve adopts high precision mechanical valve. It has advantages of fast filling

speed, high precision in liquid level and ensure that it only starts to filling when there is a can, otherwise it will stop. Using

the device structure of filling valve precover device plus supporting can bottom device, it can guarantee the maximum stability of cans when they passing in and out. Filling cylinder braces use worm-gear box going up and down to satisfy cans of different height. Float switches in the filling cylinder ensure a smooth liquid inlet state.

Hot Searches