- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Electrical

-

Dimension(L*W*H):

-

2300mm*600mm*1280mm

-

Weight (KG):

-

800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Alloy

-

cuttting:

-

A chipless cutting

-

speed:

-

2-2.5s/time

-

Suit diameter:

-

4-16mm

-

Product name:

-

Copper pipe straightening and cutting

-

Machine Type:

-

Control System

-

Straightening material:

-

Aluminium Pipe

-

Straightening Speed:

-

30-40 M/min

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Qipang

-

Voltage:

-

220V

-

Power:

-

Electrical

-

Dimension(L*W*H):

-

2300mm*600mm*1280mm

-

Weight (KG):

-

800

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

Alloy

-

cuttting:

-

A chipless cutting

-

speed:

-

2-2.5s/time

-

Suit diameter:

-

4-16mm

-

Product name:

-

Copper pipe straightening and cutting

-

Machine Type:

-

Control System

-

Straightening material:

-

Aluminium Pipe

-

Straightening Speed:

-

30-40 M/min

-

After Warranty Service:

-

Video technical support

1/4 3/8 1/2 5/8 3/4 inch Automatic straightener and cutter machine Copper Aluminum Pipe Tube straightening and cutting machine

My skype/whatsapp/wechat: +8618913219907

Full-automatic wire straightening machine , automatic wire straightening and cutting machine

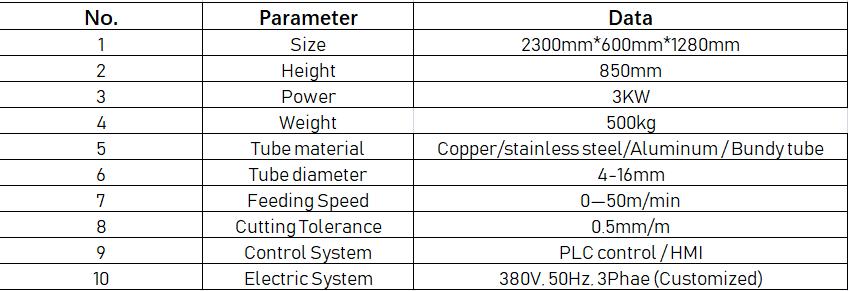

Specifications

1. Model:2300mm*600mm*1280mm

2. Drilling crew plane height: About 850mm

3. Weight:500kg

4. Power Supply: Three-phase five-wire 380v bring zero line and ground wire

5. Power: 3kw

6. Air Pressure: 0.5-0.8mpa

7. rough shape cutting to adapt to the pipe:4-16 aluminium tube;4-16 copper pipe;4-16 band pipe

8. Feeding speed: 0-50M

9. cutting ways: Single - knife direct rotation without cuttings cutting. clipping time: 2-2.5S/time. Three meters per time about 6 seconds, An eight-hour day produces about 3,000 to 4,000 pieces.

10. Equipment use field: Automobile, air conditioning, refrigerator freezer, water dispenser, home appliance, etc.

11. control principle:PLC programmable logic controller,OP-320text operation,Synchronous belt feeding,servo motor drive,Japan omron rotary encoder counting,The pneumatic original adopts SNS.

12. This machine is aimed at the following (copper tube). The tube is straightened to the straightening mechanism of the main engine, and the servo motor drives the synchronous belt to drive the pipe to the cutting-free cutting machine.Finally, it is taken over by pneumatic aggregates, and the whole process is automatic and reliable. The machine break up and operate automatically, the mold change is simple, the operation is simple, the production efficiency is high.

13. Main structure and principle:Mechanical structure: it is composed of flat rack, straightening group, feeding tube section, cutting head section and feeding frame.

Gas path control: cylinder clamp, servo drive synchronous belt feeding tube, cylinder clamp, cutting tube, pull, cylinder connection.

Circuit control system: by PLC control servo motor forward tube, after the length of the encoder, after reaching the set length, the PLC control solenoid valve action, drive the cylinder to cut off the pipe.

Processing pipe: this equipment is a single pipe equipment, and the size of the open material pipe is applicable to the mechanical limit range. Different materials need to be replaced with straightening wheel, feeding belt, mould and central pipe.

14. Machine Features:

The precision is special, can be according to the customer's product process request and according to the purchase cost budget to make the material way, the tube is cut neatly, the rate is small or no burr, no cuttings to cut any choice.

Is simple and convenient operation, automatic control and manual control two ways, the operator easy-to-learn, smooth feeding, high degree of automation, no material and reach a preset number of cutting, automatic stop.

It is easy to maintain and maintain, use pneumatic components to control and implement parts, less lubrication points, no pollution, quick and convenient replacement of parts, and easy to keep the equipment clean.

Quick installation coil, feeding frame can use double-sided active feeding plate, can prevent materials plate caused by inertia feeding is too long, or caused by the pipe is too thin and pipe strain, so as to ensure the quality of copper pipe cutting. It can also be used for flat loading rack and easy to install copper pipe.

Shanghai Qi Pang Industrial Co., LTD is a professional manufacturer which is specialized in making rolling ring linear drives , Wire straightener , Take-up Machine , Winding Machines , winding machine and coiling machine (traverse unit, rolling ring drive, linear actuators, linear motion assemblies), The company is located in the JiaDing district ,Anting Town,

Shanghai Qi Pang Industrial Co., LTD was established in 2013. Our company is a high-tech enterprise that develops and make the series polished shaft rolling ring drive and wire straightener earliest in China. The company is located in the JiaDing, Anting auto city, which is the world financial center in Shanghai. It is very convenient.

We always adhere to the talent oriented and honest business principles since our company established . Our company will continue to attract talents in various fields and advance foreign advanced technology to make our products have a high quality and precision. Our company developed a new type machine in 2015. It is a new type of machine : Frequency Take-up machine.

We always adhere to the principle of quality first, credit first and customer first. We sincerely welcome our old and new customers to cooperate and create a better future.

Except wire straigthener, C&H also supply tube straighteners, wire guides, tube guides, tube feeders and wire feeders or drive units, cable straighteners, strip straighteners, flatwire straighteners, custom built feeding machines, straightening rolls ,

preformers or preform heads , sleeve rolls for high speed and high temperature applications, computerized wire straightener and tube straightener adjustment systems.

Service before sale

1, 24 hours online .Your inquiry will be quick reply by email .

Also can go through all questions with you by any online chatting tools (Wechat ,Whatsapp ,Skype ,Viber ,QQ , TradeManager )

2,Professionally and patiently introduction,details pictures and working video to show machine

Service on sale :

1,Test every machine and inspect the machine seriously .

2,Send the machine picture which you order , then packing it with standard export wooden box after you confirm the machine is ok .

3,Delivery:If ship by sea .after delivery to seaport .Will tell you the shipping time and arrival time . Finally, send all original documents to you by Express For Free.

If delivery it by Express to your door(DHL, TNT,Fedex, etc) or by air to your airport, Or logistic to the warehouse which you request . We will tell you the tracking number after delivery.

Service after sale

1, Free insurance for goods

2, 24 hours online to solve any problem . Supply you English manual book and technical support , maintain and install video to help you solve the problem, or dispatch worker

Contact us