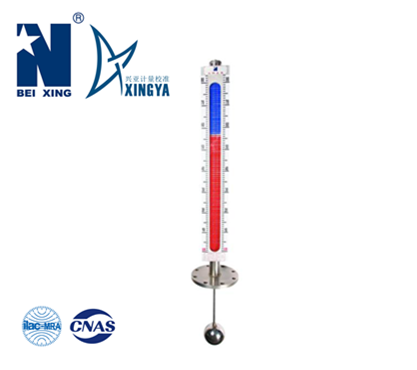

- Product Details

- {{item.text}}

Quick Details

-

Measuring range:

-

500~3000mm

-

Error:

-

±10mm

-

Working pressure:

-

Working pressure

-

Medium temperature:

-

-40~300

-

Medium density:

-

≥0.7g/cm3

-

Flange connection:

-

DN150,PN1.6,standard HG20592~20593-97(or other standard)

-

Meet liquid material:

-

1Cr18Ni9Ti, 304, 316, Ti

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

BEIXING

-

Model Number:

-

UFZ

-

Measuring range:

-

500~3000mm

-

Error:

-

±10mm

-

Working pressure:

-

Working pressure

-

Medium temperature:

-

-40~300

-

Medium density:

-

≥0.7g/cm3

-

Flange connection:

-

DN150,PN1.6,standard HG20592~20593-97(or other standard)

-

Meet liquid material:

-

1Cr18Ni9Ti, 304, 316, Ti

Main technology parameters :

| Measuring range | 500~3000mm |

| Error | ±10mm |

| Working pressure | ≤ 1.6MPa |

| Medium temperature | 40~300 |

| Medium density | :≥0.7g/cm 3 |

| Flange connection | DN150,PN1.6,standard HG20592~20593-97(or other standard) |

| Meet liquid material | 1Cr18Ni9Ti, 304, 316, Ti |

Structure Principle:

Shenyang Beixing Meter Manufacture Co., Ltd. was founded in August of 1995. We are located at Shenyang Economic & Technological Development Area and our company covers an area of 18,000sqm. Our company is specialized in manufacturing flow & level measuring instruments, chemical glass products, chemical glass pipes and special glass apparatus. Meanwhile, we also act as an agent of mechanical & electrical products, pressure instruments, chemical reagents, chemical materials, laboratory apparatus & science equipment, contract to design the instrument and meter engineering, chemical industry pipeline & laboratory auxiliary projects, process on given materials and take

mechanical

manufacturing.

Shenyang Beixing Meter Manufacture Co., Ltd. was founded in August of 1995. We are located at Shenyang Economic & Technological Development Area and our company covers an area of 18,000sqm. Our company is specialized in manufacturing flow & level measuring instruments, chemical glass products, chemical glass pipes and special glass apparatus. Meanwhile, we also act as an agent of mechanical & electrical products, pressure instruments, chemical reagents, chemical materials, laboratory apparatus & science equipment, contract to design the instrument and meter engineering, chemical industry pipeline & laboratory auxiliary projects, process on given materials and take

mechanical

manufacturing.

William Gong

Shenyang Beixing Meter Manufacture Co., Ltd.

Add:No.16, North No.26 Road, Shenyang Economic Technology Developing Area Shenyang, China

Web: www.beixing.com.cn

Tel: +86 - 0 24-89255802

Fax: +86 - 0 24-89255800

Cell/wechat: +86 18342068061

Email;sale04 ( @ ) beixing.com.cn