- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Metal

-

Surface Treatment:

-

Sand Blasting Etc

-

Technics:

-

Casting/CNC/Coating

-

Application:

-

Precision Casting/Aluminium Casting Parts/Auto Parts/Tool Parts

-

Size:

-

Customized

-

Color:

-

Silver/Customizable

-

Certification:

-

ISO9001/ISO14001/IATF16949

-

Standard:

-

JIS/ANSI/API/BS/DIN/GB etc.

-

OEM:

-

Accept

-

Sample:

-

Free

Quick Details

-

Place of Origin:

-

liaoning

-

Brand Name:

-

ST

-

Model Number:

-

DW-A5

-

Material:

-

Metal

-

Surface Treatment:

-

Sand Blasting Etc

-

Technics:

-

Casting/CNC/Coating

-

Application:

-

Precision Casting/Aluminium Casting Parts/Auto Parts/Tool Parts

-

Size:

-

Customized

-

Color:

-

Silver/Customizable

-

Certification:

-

ISO9001/ISO14001/IATF16949

-

Standard:

-

JIS/ANSI/API/BS/DIN/GB etc.

-

OEM:

-

Accept

-

Sample:

-

Free

Specification

|

item

|

value

|

|

Place of Origin

|

Liaoning China ( Mainland )

|

|

Brand Name

|

ST

|

|

Model Number

|

DW-A5

|

|

Material

|

Iron/Aluminum/Zinc/Other metals

|

|

Surface Treatment

|

Sand Blasting

|

|

Technics

|

Aluminum casting / CNC / coating

|

|

Size

|

Customized

|

|

Color

|

Silver / Customizable

|

|

Certification

|

SO9001 / S014001ATF16949

|

|

Standard

|

JIS / ANSI / API / BS / DIN / GB etc

|

|

OEM

|

Accept

|

|

Sample

|

Free

|

The main advantages of aluminum die castings

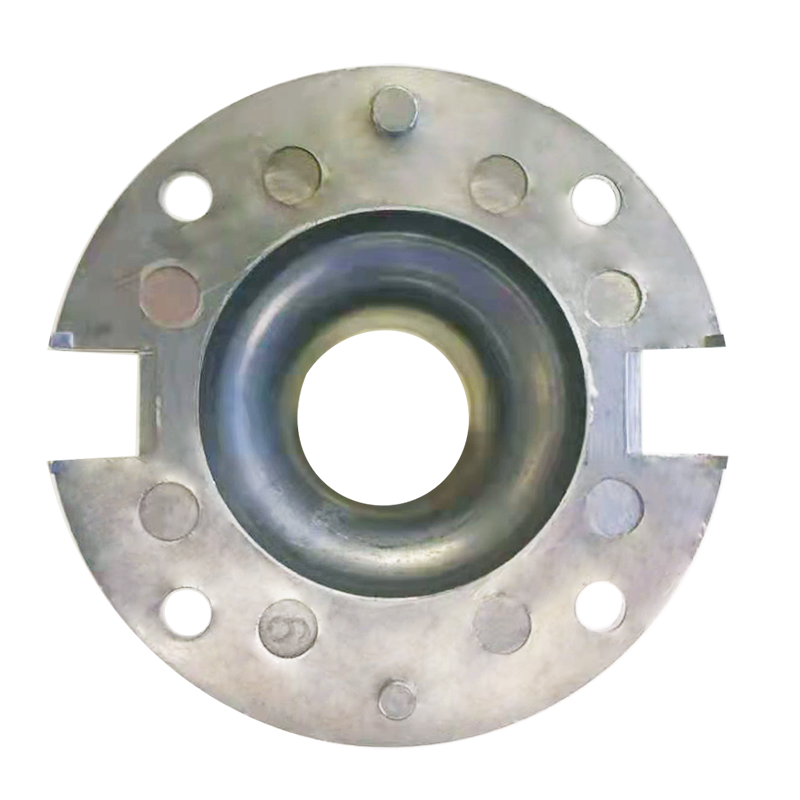

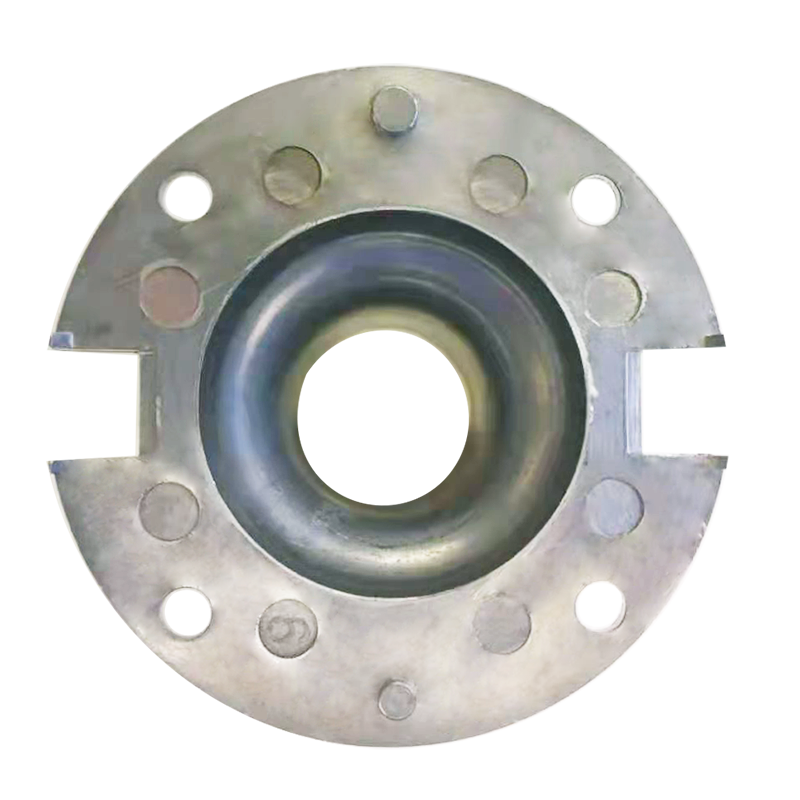

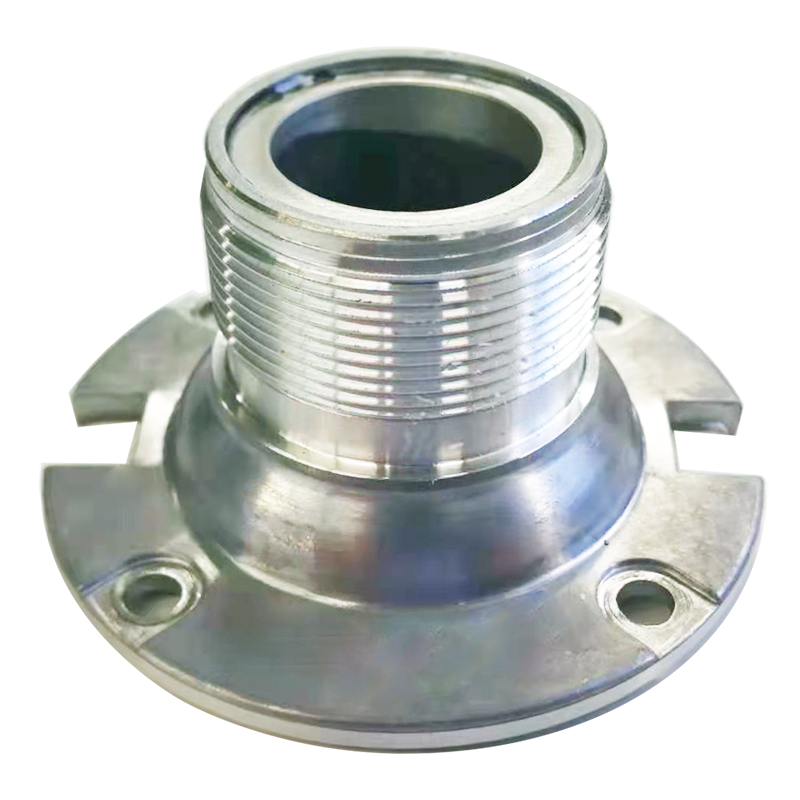

1. Aluminum die-casting parts are beautiful in appearance, light in weight and convenient to transport.

2. Aluminum alloy has low density, higher strength and corrosion resistance, which can reduce the weight of the structure.

3. Good surface gloss and high casting performance.

4. The mechanical properties and tensile strength of aluminum die castings, and the surface of the material has strong resistance to plastic deformation caused by hard objects or friction.

5. The working temperature, humidity, contact medium and air tightness of aluminum die castings can achieve accuracy and dimensional stability.

Die casting production process

Die-casting orders → die-casting mold design → die-casting mold manufacturing → die-casting machine test mold, mold installation →die-casting demoulding → shot blasting, sandblasting → polishing/grinding, cleaning → electroplating, painting → die-casting coarse/finishing processing →q

uality inspection

→

shipment

Surface treatment

We use a variety of surface treatment,anodizing,brushing,galvanized,laser engraving,plating,polishing,powder coating,sandblasting,silk prinnting,you have a variety of options.

Our die casting products

Our factory custom produces many types of die casting products,vehicle parts,lighting products,pump,motor housing,wheel and bracket etc.Productes with high precision, short construction period and favorable prices.

Customer praise

We have been affirmed by our customers, and they have given us faith. We pursue better, continuous reform and innovation, and aim to realize customer value, and build a grand blueprint with customers.

Hot Searches