- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v automatic potato peeling machine

-

Power:

-

1.1kw small potato peeling machine

-

Dimension(L*W*H):

-

1600*850*800mm automatic potato peeling machine

-

Weight:

-

220 KG

-

Machinery Function:

-

brush roller potato peeling machine

-

Output product name:

-

potato peeling machine industrial

-

Product name:

-

Industrial Automatic Brush Roller Peeler Small Potato Peeling Machine

-

Application:

-

Machine for peeling potato and carrots.

-

Capacity:

-

400kg/h

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE ISO

Quick Details

-

Raw material:

-

Water, Vegetables, cassava washing and peeling machine

-

Model Number:

-

LG-XM800 small potato peeling machine

-

Brand Name:

-

LONGER potato peeling machine peeler

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380v automatic potato peeling machine

-

Power:

-

1.1kw small potato peeling machine

-

Dimension(L*W*H):

-

1600*850*800mm automatic potato peeling machine

-

Weight:

-

220 KG

-

Machinery Function:

-

brush roller potato peeling machine

-

Output product name:

-

potato peeling machine industrial

-

Product name:

-

Industrial Automatic Brush Roller Peeler Small Potato Peeling Machine

-

Application:

-

Machine for peeling potato and carrots.

-

Capacity:

-

400kg/h

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Certification:

-

CE ISO

Size Information

Features

1. The roller cleaning (peeling) machine has a beautiful appearance and convenient operation, and has a large cleaning and peeling volume.

2. High efficiency and low energy consumption,

3. It can be continuously cleaned, simple in operation and long in service life.

4. The cleaning roller is a special processing nylon rope rolling material, which is peeled to be hardened material, both of which are durable and have good wear resistance.

Size Chart of This

Small Potato Peeling Machine

|

Model

|

Power

|

Dimension

|

Weight

|

Capacity

|

|

LG-XM800

|

1.1kw/380v

|

1600*850*800mm

|

220kg

|

400kg/h

|

Product Description

Automatic Potato Peeling Machine

Introduction

The

brush roller potato peeling machine

is mainly composed of t

ank, power motor, transmission, hair roller, high pressure spray pipe. Each

small potato peeling machine

is equipped with 9 brushes, t

he material is divided into ordinary nylon wool roller and diamond roller. The diameter is 120mm, and length of the hair is 2cm.

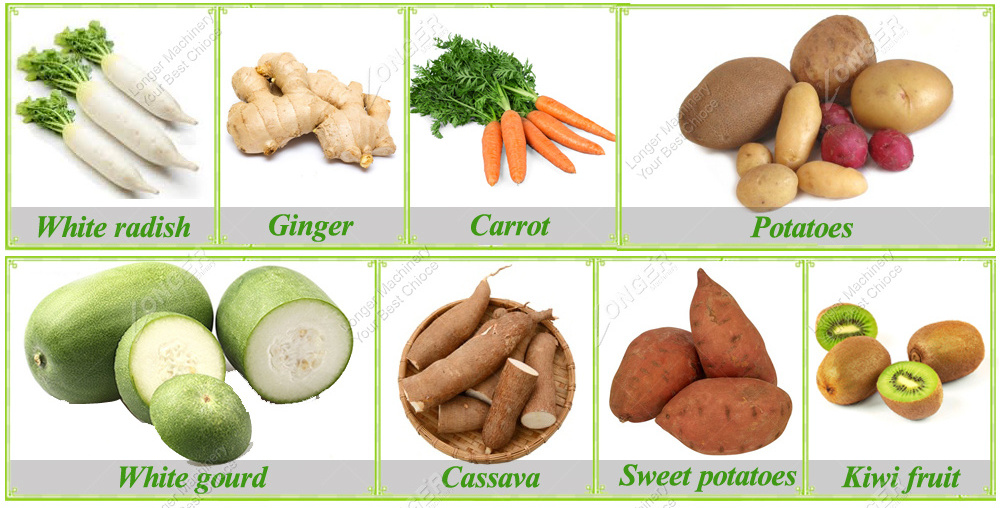

Application of P otato Peeling Machine Peeler

This

small potato peeling machine

adopts the principle of brush friction, which is widely used for cleaning and peeling of round and oval fruits and vegetables such as ginger, carrot, hawthorn, potato, sweet potato, rehmannia, Polygonum, and Radix.

Detailed Images

Water Spray

The water spray can be customized and you can choose to equip or not according to raw material.

Outlet

The washed material will come out here while open the baffle by pressing the button.

Roller Brush

The material is divided into ordinary nylon wool roller and diamond roller.

The roller speed is 280r/min, and t

he diameter is 120mm, and length of the hair is 2cm.

Removing Wheels

The machine can be customized with four wheels and easy to remove.

Our Advantages

This

automatic potato peeling machine

adopts food grade 304 stainless steel material to raise the whole body. The motor is placed at the bottom. The waste collection area under the machine has enough space for the workers to remove the waste. The new filter screen can completely separate the waste residue and waste water. It is easily scraped off on the filter screen, and the waste water is automatically drained under the filter screen.

Application Scenario

Related Products

FAQ

1. how many types of the

small potato peeling machine

?

Brush cleaning machine is divided into soft brush and hard brush, if need to peel or soft material, you can choose soft brush (actually according to customer demands and material characteristics). By add extra 500 yuan, you can install a time metering equipment.

2. What is the life time of a roller? How many hair rollers are configured per machine?

The model number is determined according to the length of the roller; the service life of the roller is 4-5 years and each machine is equipped with 9 rollers.

3. What is the diameter of the normal hair roller and the length of the hair?

The diameter is 120mm, and length of the hair is 2cm.

4. What is the material of the brush?

The material is divided into ordinary nylon wool roller and diamond roller. Generally, in the large production line, it will be equipped with two spiral propulsion. The first one is the ordinary wool roller for pre-washing , and the second one is the corundum roller for thoroughly cleaning and peeling.

5. How to maintenance the machine? and How often need lubrication?

You need to lubricate the bearing once every 6 months, and chain once a month.

6. How is the speed of the roller? How long does it take to change a normal hair roller?

The roller speed is 280r/min. For skilled operation, it takes 1 hour to change the roller, unskilled 2-3 hours.

7. Instructions and precautions?

1) Start the equipment, pay attention to the correct running direction, then open the water valve to add materials;

2) Do not mix hard materials in the material to protect the brush from damage.

3) Chains and bearings should be regularly filled with grease.

Hot Searches