- Product Details

- {{item.text}}

Quick Details

-

Year:

-

2022

-

Power (kW):

-

55 kW

-

Weight (KG):

-

4800 KG

-

Color:

-

White

-

Name:

-

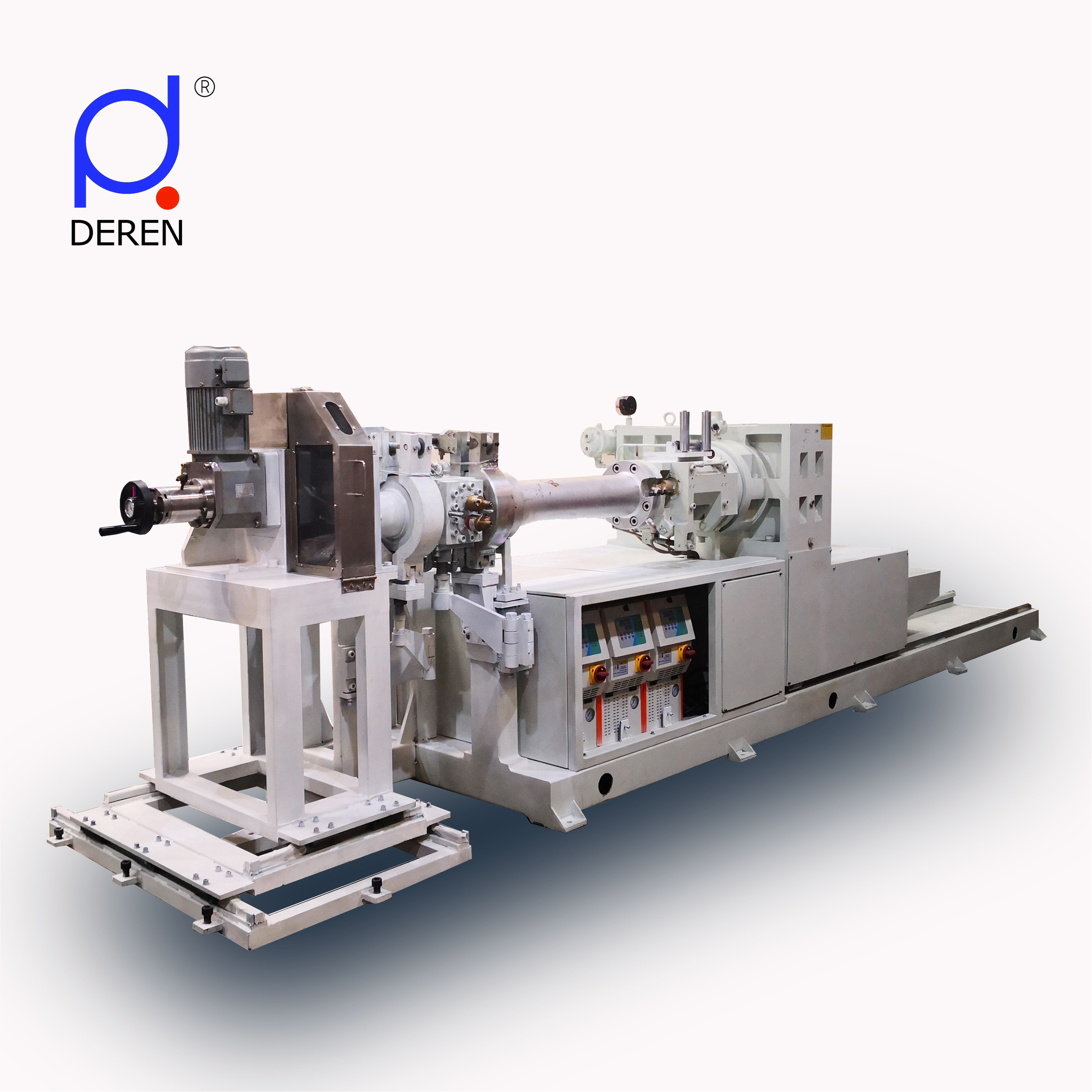

DRL series cold feeding rubber precision preformer

-

Screw diameter:

-

90mm

-

Draw Ratio of Screw:

-

12:1L/D

-

Screw rotation speed:

-

6-60Rpm

-

Speed of gear pump:

-

4-50Rpm

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

deren

-

Dimension(L*W*H):

-

5.5 1.2 1.65

-

Year:

-

2022

-

Power (kW):

-

55 kW

-

Weight (KG):

-

4800 KG

-

Color:

-

White

-

Name:

-

DRL series cold feeding rubber precision preformer

-

Screw diameter:

-

90mm

-

Draw Ratio of Screw:

-

12:1L/D

-

Screw rotation speed:

-

6-60Rpm

-

Speed of gear pump:

-

4-50Rpm

Product Description

Traditional preform products (blanks) are produced by precision preform machines with fixed speed and precise plunger displacement control. The production process is not continuous. Because special mixers are needed to provide preheated and mixed rubber, and each batch must be re-fed, the labor intensity is considerable. Extrusion/gear pump technology was used in cold feed preform to improve the traditional rubber blank manufacturing technology.

Strip cold rubber into the extruder feeding port automatically after plasticizing, preheating, and then sent to the entrance to

the gear pump, the pump driven into the die, the die of the rotating cutter will cut into the required size, rubber in the system, the use of gear pump technology for extrusion efficiency and product precision provides important guarantee. Gear pump inside the rotor and bearings have been tested for many years proved very reliable, without frequent replacement.

The control part of the system is a special PLC. Pressure sensors are installed at the inlet and outlet of the gear pump to ensure that the pressure at the inlet of the gear pump is maintained at a certain level. In addition, the extrusion speed can be controlled by adjusting the inlet pressure of the gear pump, so that the rubber compound can be injected into the gear pump stably under the required pressure conditions.

Strip cold rubber into the extruder feeding port automatically after plasticizing, preheating, and then sent to the entrance to

the gear pump, the pump driven into the die, the die of the rotating cutter will cut into the required size, rubber in the system, the use of gear pump technology for extrusion efficiency and product precision provides important guarantee. Gear pump inside the rotor and bearings have been tested for many years proved very reliable, without frequent replacement.

The control part of the system is a special PLC. Pressure sensors are installed at the inlet and outlet of the gear pump to ensure that the pressure at the inlet of the gear pump is maintained at a certain level. In addition, the extrusion speed can be controlled by adjusting the inlet pressure of the gear pump, so that the rubber compound can be injected into the gear pump stably under the required pressure conditions.

|

Technical Description of DRL Series Cold Feed Rubber Precision Preformer

|

|

|

|

1

|

Cold Feed Precision Preformer is to cut the mixing rubber into the shape and weight required by customers. The weight accuracy of blank is controlled within ±1%.

|

|

|

2

|

PLC control, process parameter storage, direct data call instruction, easy operation.

|

|

|

3

|

The screw and barrel are electric disengaging from the structure, which can effectively reduce the labor intensity, facilitate the

replacement of rubber and facilitate the cleaning.

|

|

|

4

|

Conveyor net cover and conveyor adopt stainless steel material to prevent rubber pollution.

|

|

|

5

|

Electronic scale closed circuit feedback, one key to calibrate the weight of rubber blank.

|

|

|

6

|

Equipment fault alarm and icon display fault location, regularly remind workers to spot check and calibrate the weight of the

rubber blanks.

|

|

|

7

|

The machine head, cutting knife and other devices are interlocked, and all-round protection is provided to effectively avoid the

occurrence of work-related injuries.

|

|

|

8

|

Searchlight with the machine head, easy to clean, to avoid the situation of bad cleaning corner.

|

|

|

9

|

The system pressure and extrusion pressure are displayed digitally on the touch screen.

|

|

|

10

|

When the new product is trial-produced, the PLC operation provides reference data to further simplify the operation process.

|

|

|

11

|

All machine heads are sealed with stainless steel to prevent rubber from spilling on the ground (polluting the environment, waste

of rubber, etc.).

|

|

|

12

|

Continuous process and high production efficiency:DRL cold feeding preformer can input strip rubber uninterruptedly to produce high-precision blank, so it does not need to consumeman power to continuously add material.Because of continuous production, there is no unqualified rubber blank in the start-up and shutdown stages of hydraulic precision pre-forming machine, which reduces material loss and greatly improves production efficiency.Because of the continuous production, there is no unqualified rubber blank produced under the start-up and shutdown stages of hydraulic precision preformer, which reduces material loss and greatly improves production efficiency.

|

|

Why Choose Us

1.Technical training

Provide CD training video tutorial,Or on-site training, technical personnel, equipment operation and

maintenance personnel.But before the training according to the need for training program and data, and make the training of

personnel to master the skills related to the equipment needs, provide necessary skills to ensure safe use and maintenance equipment.

maintenance personnel.But before the training according to the need for training program and data, and make the training of

personnel to master the skills related to the equipment needs, provide necessary skills to ensure safe use and maintenance equipment.

2.

Offer lifetime technical support

The company's products provide technical support for life.During the product

operation (including product has passed the quality guarantee period) components, parts damage, company can Real-time online communication to help solve the problem,or send professional and technical personnel for repair and replacement.

3. The warranty period free warranty

operation (including product has passed the quality guarantee period) components, parts damage, company can Real-time online communication to help solve the problem,or send professional and technical personnel for repair and replacement.

3. The warranty period free warranty

In the warranty period due to the factors of equipment damage, by the company responsible for free repair, maintenance, replacement.Because of human (not our personnel) and damage caused by natural disasters, the company responsible for providing maintenance service free of artificial cost, charge material cost accordingly.

4.

Pay a return visit

Cooperate with customer for technical equipment inspection, review, can save a lot of problems for customers.

Cooperate with customer for technical equipment inspection, review, can save a lot of problems for customers.

5.

Fast response

Ensure information feedback timely communication, strong service network, and into the week to service for you, in time to answer customer inquiries, when necessary, can in not deviating from the customer needs to send professional personnel arrived at the scene, to repair or parts replacement equipment.

Ensure information feedback timely communication, strong service network, and into the week to service for you, in time to answer customer inquiries, when necessary, can in not deviating from the customer needs to send professional personnel arrived at the scene, to repair or parts replacement equipment.

Product packaging

Hot Searches