- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

2780003

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

chunse

-

Model Number:

-

2780004

-

Product name:

-

aluminum paste for ink

-

Color:

-

silver

-

MOQ:

-

1kg

-

Form:

-

Paste Form

-

Grade:

-

Industiral Grade

-

sample:

-

Avaiable

-

Key words:

-

metallic silver effect

-

brand:

-

chunse

-

Delivery time:

-

3-5 working days

Quick Details

-

CAS No.:

-

2780002

-

Other Names:

-

Coated silver paste

-

MF:

-

please consult the customer service staff

-

EINECS No.:

-

2780003

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

chunse

-

Model Number:

-

2780004

-

Product name:

-

aluminum paste for ink

-

Color:

-

silver

-

MOQ:

-

1kg

-

Form:

-

Paste Form

-

Grade:

-

Industiral Grade

-

sample:

-

Avaiable

-

Key words:

-

metallic silver effect

-

brand:

-

chunse

-

Delivery time:

-

3-5 working days

Specification

|

item

|

value

|

|

CAS No.

|

2780002

|

|

Other Names

|

Coated silver paste

|

|

MF

|

no

|

|

EINECS No.

|

2780003

|

|

Place of Origin

|

China

|

|

|

Guangdong

|

|

Usage

|

Coating Pigment, Cosmetic Pigment, Plastic & Rubber Pigment, Leather Pigments, Nail art paint

|

|

Brand Name

|

chunse

|

|

Model Number

|

2780004

|

|

Type

|

aluminum

|

|

Style

|

Inorganic Pigment

|

|

Product name

|

aluminum paste for ink

|

|

Color

|

Picture

|

Product Description

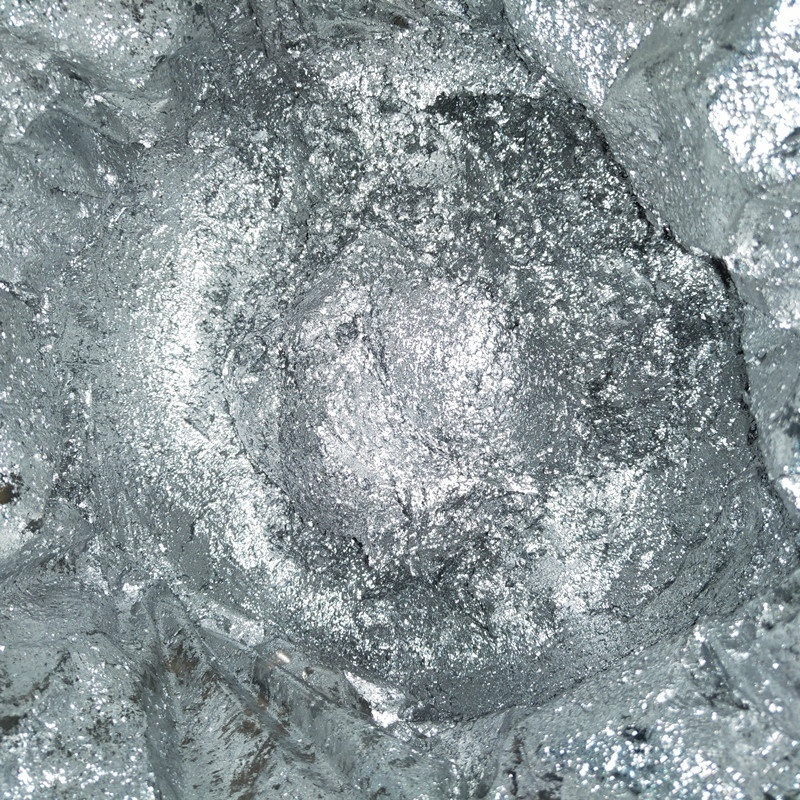

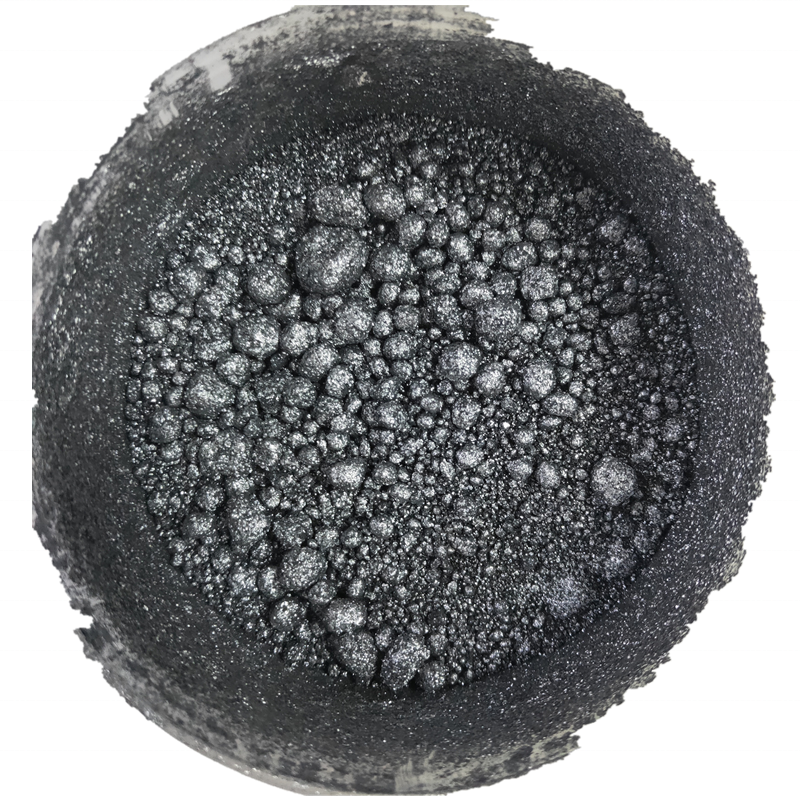

This product is our company: non-floating water-based imitation electroplating aluminum silver paste, which is made of high-purity raw materials.

Has excellent metallic feel and covering power. The water-based aluminum pigment whose surface has been treated with a special silica process has a uniform and dense coating thickness, which does not affect the metallic luster of the aluminum sheet. It produces the phenomenon of "rising sound", and has good high temperature resistance and yellowing resistance. Suitable for water-based coatings and ink systems.

Applications

This product is widely used in water-based baking paint, water-based plastic paint, water-based ink, water-based architectural coatings, etc.

technical parameter

Solid content: 65%

Aluminum content: 53%

Solvent Type: PM (Propylene Glycol Methyl Ether)

Particle size: 4, 5, 7.9.15.20.35.55.65UM (microns)

Storage Instructions

WF series non-floating water-based imitation electroplating aluminum silver paste has a shelf life of 12 months when unopened. If it exceeds the shelf life, it is recommended to do a small test before use, and it is recommended to store it for no more than 3 months after it is made into paint.

Storage conditions: Please avoid direct light, the temperature does not exceed 25 ℃, the humidity does not exceed 60, please seal in time after taking the material (to prevent the solvent in the water-based silver paste from quickly volatilizing, affecting the effect of future use).

Stability test (recommended to test before use)

Suggestion: 1 part of water-based aluminum silver paste + 9 parts of water-based base material (PH=6-8.5) to make 200 grams of paint, stored in an airtight container at 40°C

Store for 30 days or 50°C for 7 days, observe the overall performance change after storage and the outgassing volume does not exceed 10ML

How to use the product

Step 1: It is recommended to pre-disperse the water-based aluminum silver paste in a co-solvent (ether, alcohol or deionized) in a ratio of 1:1.5 or 1:2.

One or more of sub-waters), the effect of adding wetting dispersant during pre-dispersion is better;

The second step: water-based resin (emulsion) and other additives are added to the dispersion container according to a certain formula ratio, and stirred evenly;

The third step: add the dispersed aluminum slurry to the dispersed water-based resin (emulsion) system under stirring, and the low

Stir quickly and evenly (it is recommended to use paddle-type dispersion, and the speed should be controlled at 300-500rpm) to ensure complete dispersion, so that the paint

Try to get better results.

declare

All the above information, data and expressions are the reference data obtained by the company's internal experiments and are based on the current

understanding, and believe that its accuracy and reliability, only for customer reference. Due to different system, formula, use environment and other conditions,

Users themselves are solely responsible for the suitability and completeness of this material for their own applications. Please customers carefully before using

detection to prevent unnecessary economic losses. The company does not assume any responsibility.

Packing & Delivery

Hot Searches