- Product Details

- {{item.text}}

Quick Details

-

Welding Diameter:

-

200-750mm

-

Usage:

-

longitudinal seam welding

-

Voltage:

-

380V/220V

-

Weight (KG):

-

200 KG

-

Name:

-

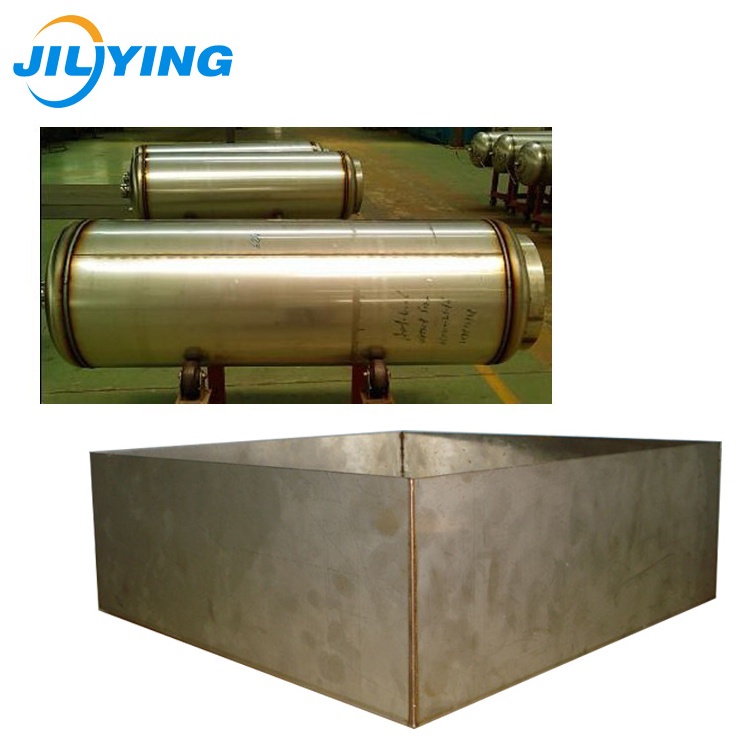

Longitudinal Seam Welding Machine

-

Application:

-

Solar Water Heater Tank

-

Welding Material:

-

Aluminum

-

Function:

-

Steel Tank Welding

-

Type:

-

Arc Welding

-

Working mode:

-

Auto Longitudinal Seam Welder

-

Material:

-

Stainess Steel

-

Feature:

-

High Efficiency

-

Color:

-

Customer's Require

-

Welding Thickness:

-

1mm-8mm

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support, Video technical support

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

TOPRESS

-

Forming Time:

-

1min

-

Welding Diameter:

-

200-750mm

-

Usage:

-

longitudinal seam welding

-

Voltage:

-

380V/220V

-

Weight (KG):

-

200 KG

-

Name:

-

Longitudinal Seam Welding Machine

-

Application:

-

Solar Water Heater Tank

-

Welding Material:

-

Aluminum

-

Function:

-

Steel Tank Welding

-

Type:

-

Arc Welding

-

Working mode:

-

Auto Longitudinal Seam Welder

-

Material:

-

Stainess Steel

-

Feature:

-

High Efficiency

-

Color:

-

Customer's Require

-

Welding Thickness:

-

1mm-8mm

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support, Video technical support

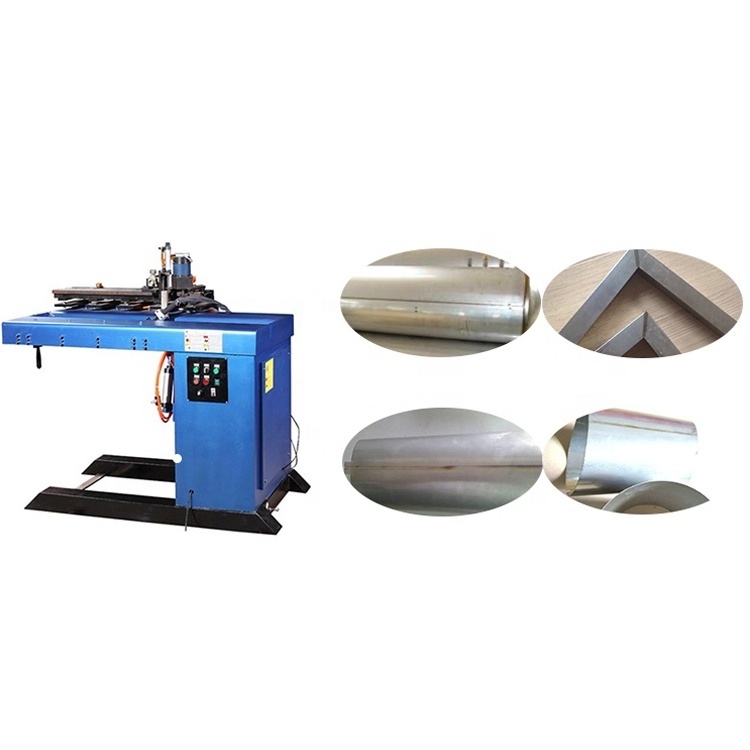

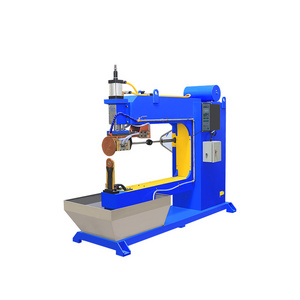

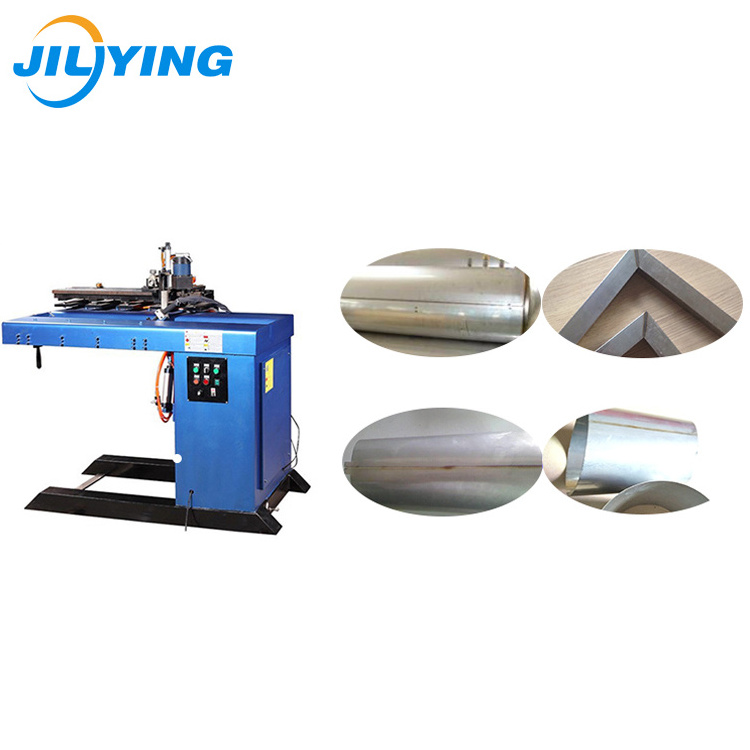

Fuel Tank Longitudinal Steel Barrel Seam Welding Machine

Main Technical Data

| Model No. | Welding length(mm) | Min. diameter(mm) | Max. diameter(mm) |

| ZF-500 | <=500 | 75 | 750 |

| ZF-1000 | <=1000 | 100 | 750 |

| ZF-1500 | <=1500 | 120 | 750 |

| ZF-2000 | <=2000 | 160 | 750 |

| ZF-2500 | <=2500 | 200 | 750 |

| ZF-3000 | <=3000 | 270 | 750 |

1. Key-type pneumatic pressing device is applied to camp the work piece.

This device provides force evenly to work piece and prevents deformation.

2. It is widely applied in high quality welding and lowdeformation straight seam. Use in such field:

petrochemical industry, solar water heater manufacture, pipeline and automobile industry.

3. Controlled by PLC, driven by DC motor, and staples speed regulation,

with control System to realize automatic welding, and equipped with straight oscillator for optional choice.

4. With different protection lining on the lower side.

The welding seam can be welded through. Therefore the both sides of the welding seam can be shaped

with single-side welding.

5. Its welding thickness is 1mm-8mm.

Welding speed is 2m/min-2min.

6. Longitudinal automatic welding machine use several welding method,

such as argon submerged welding, gas shielded welding and plasma welding etc.

The working conditions and environments used are:

1. Input power: 380V ± 5% / 50Hz ± 1, three-phase five-wire (according to customer requirements) or Input power: 220V ± 5% / 60Hz ± 1, three-phase

2. Ambient temperature: 0℃-45℃

3. At 40 ℃: relative humidity≤50%; at 20℃: relative humidity≤85%

The use of occasions should not seriously affect the use of welding gas, steam, chemical deposition, dust, mold and other easy fuel and corrosive substances, and does not allow severe vibration and bumps. The equipment should be placed in a dry and ventilated place and prevent sunlight, direct and rain.

Contact name: Belinda Sun

Email: belinda@ weldcnc.com

Whatsapp/Wechat/Mob: +86 15542318526

1.Installation

Free installation and commissioning,travel expense is on foreign customer.(Including round ticket and accommodation cost)

2.Personnel training

Free training for about one week.

3. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)