- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

380V/220/,50HZ/60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PLANET MACHINE

-

Dimension(L*W*H):

-

2800*2100*2300mm, According to customer requirements

-

Weight:

-

5000 KG

-

Filling material:

-

CSD

-

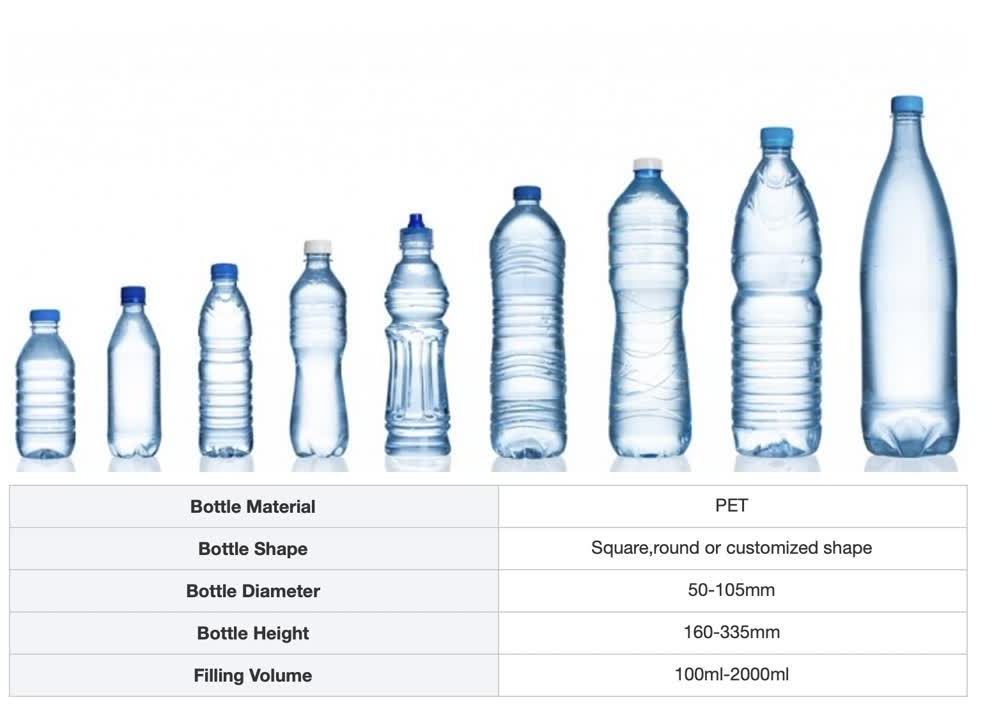

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-36000bph

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304/316

-

Filling volume:

-

200ml-2000ml

-

Product name:

-

Automatic Rotary 3 in 1 PET Plastic Bottled CSD Filling Machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, Other

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood, Other

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.5%

-

Voltage:

-

380V/220/,50HZ/60HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

PLANET MACHINE

-

Dimension(L*W*H):

-

2800*2100*2300mm, According to customer requirements

-

Weight:

-

5000 KG

-

Filling material:

-

CSD

-

Bottle type:

-

PET Plastic Bottle

-

Capacity:

-

2000-36000bph

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel 304/316

-

Filling volume:

-

200ml-2000ml

-

Product name:

-

Automatic Rotary 3 in 1 PET Plastic Bottled CSD Filling Machine

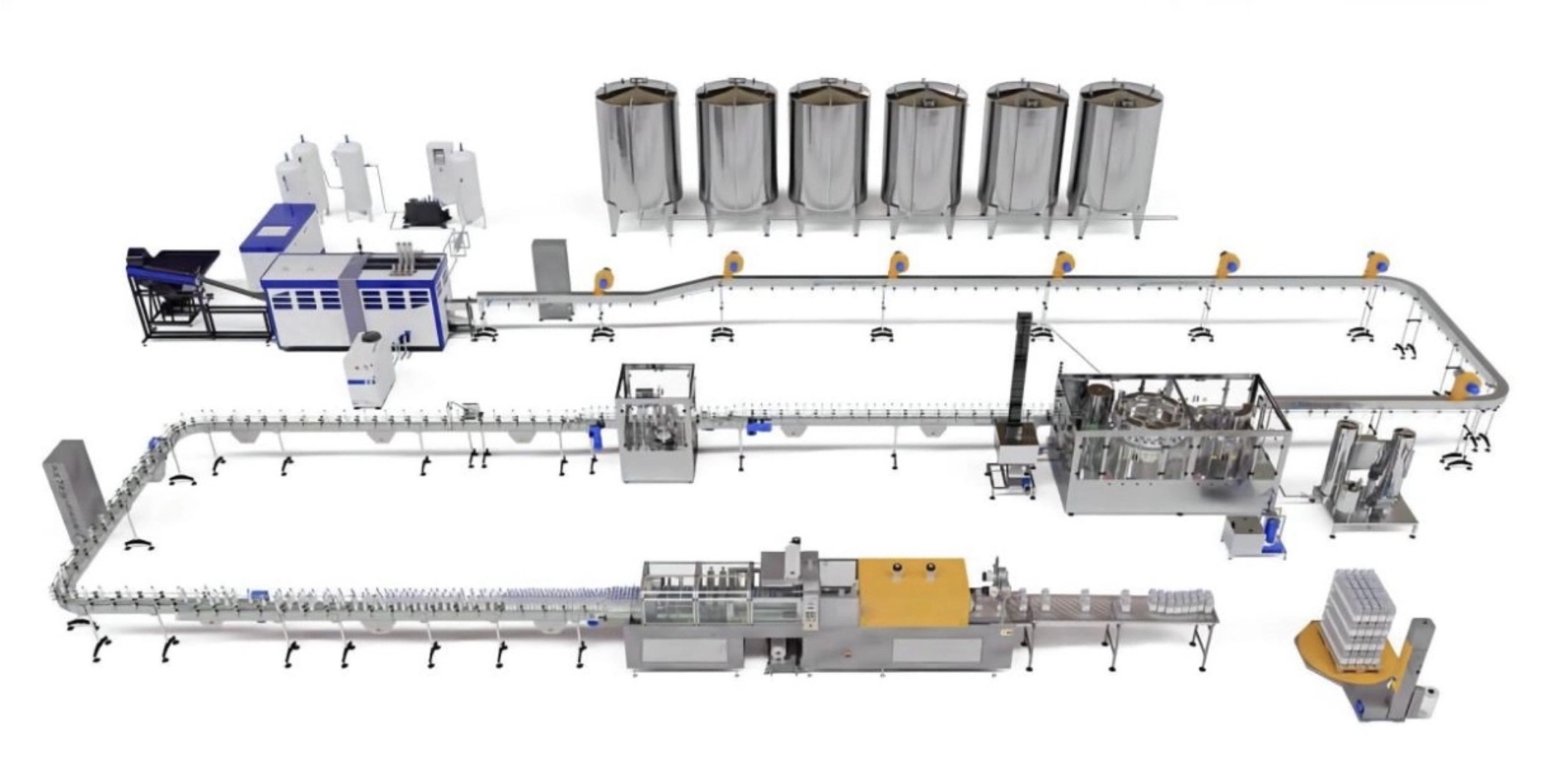

"Carbonated Soft Drink Filling Production Line From A-Z"

Products Description

Turn-key Solution

Turn-key Solution

The carbonated beverage filling production line produced by Planet Machinery has good stability, easy operation and supports customization. The carbonated beverage filling equipment is suitable for PET bottles with various capacities and shapes.The carbonated beverage filler can fill carbonated beverage, soft drink, soda etc.

The carbonated beverage filling machine adopts iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others. The isostatic filling machine generally maintains a certain filling pressure in the storage tank. When the container to be filled enters the filling machine, the container is first Inflated, the gas can be compressed air or carbon dioxide gas, preferably carbon dioxide gas. When the pressure in the container and the pressure in the storage tank are the same, the self-weight of the liquid is filled through the open filling valve. During the filling process, the gas in the container is smoothly exported and returned to the storage tank or to the gas chamber.

The carbonated beverage filling machine adopts iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others. The isostatic filling machine generally maintains a certain filling pressure in the storage tank. When the container to be filled enters the filling machine, the container is first Inflated, the gas can be compressed air or carbon dioxide gas, preferably carbon dioxide gas. When the pressure in the container and the pressure in the storage tank are the same, the self-weight of the liquid is filled through the open filling valve. During the filling process, the gas in the container is smoothly exported and returned to the storage tank or to the gas chamber.

Machine layout

CSD pre-treatment system

-->

Automatic bottle blowing machine --> Air conveyor system-->Washing,filling ,capping 3in1 machine-->Conveyor system-->Automatic sleeve labeling machine-->Automatic film shrink packing machine/Carton packing machine

Product Paramenters

|

Containers and Specifications

|

|

|

|

|

||||

|

Project Name:

Full Automatic Complete CSD 2000-30000bph Production Line |

|

|

|

PH≥4.6

CSD |

||||

|

Material

|

Shape

|

Filling volume

|

Filling level(mm)

|

Neck type

|

||||

|

PET Bottle

|

Square or Round Bottle

|

100-2000ml

|

Distance from bottle neck

According request

|

As request

|

||||

|

Adjustable specifications

of the bottle type |

【Middle Mould Base】Bottle diameter ≤105mm Bottle Height≤335mm

|

|

|

|

||||

|

|

Customers need to buy additional change-over parts for the different bottles.

If using square bottles, then bottle separating system will be added. |

|

|

|

||||

|

Container Label & Control Mode

|

|

Packaging system

|

|

Palletizing system

|

||||

|

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automaticc |

|

Packing system

|

Min, Spec.

|

Manual

Low position gantry palletizer Robot Palletizer High position gantry palletizer Single Arm Palletizer Manual Palletizer |

||||

|

|

|

Manual

Film shrinker Wrap Around packer Robert Packing Machine |

1*2

2*3 3*4 4*6 3*5 |

|

||||

|

User Ambient Conditions

|

|

Temperature:0~4℃;Humidity:No dew

|

|

|

||||

|

User Electrical Supply Specification

|

|

Voltage:380V±5%, 3phase; Frequency:50HZ±1%

|

|

|

||||

Product Details

Air Conveyor.

- Air conveyor is fixed on the floor, with fan installed on the top.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

- Rack made by high quality carbon steel welded.

- Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

- Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

- All are made of stainless steel SUS 304 /316.

- Rack made by high quality carbon steel welded.

Bottle Washing.

Bottle Washing.

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

Conventional type filling.

304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

Bottle Capping.Bottle Capping.

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during c

apping- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

apping- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Main Features.

Main Features.

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, German SIEMENS, OMRON.

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, German SIEMENS, OMRON.

auxiliary equipment

Bottle Blowing Molding Machine

Capacity:Up to 24,000 BPH

Water Treatment& CSD pre-treatment system

2T-30T/H

BOPP hot glue labeling machine

capacity 6000-24000bph

Shrink sleeve labeling machine

capacity 6000-24000bph

Shrink wrapping machine

capacity: 10-25 bags/min

Case pack machine

capacity: 10-25 box/min

Hot Searches