- Product Details

- {{item.text}}

Quick Details

-

Nozzle Number:

-

1

-

Axis Number:

-

3-Axis X,Y,Z

-

Table Size:

-

<700*700mm

-

Z-axis Adjustment:

-

0-100mm

-

Cleaning:

-

Auto

-

Glue viscosity:

-

<3500

-

Power Supply:

-

AC:220±10%,50/60HZ, 2.5Kw

-

Control Method:

-

PLC+Touch screen

-

Dimension(mm):

-

L1300*W1100*H1500

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

ITC

-

Weight (KG):

-

550

-

Nozzle Number:

-

1

-

Axis Number:

-

3-Axis X,Y,Z

-

Table Size:

-

<700*700mm

-

Z-axis Adjustment:

-

0-100mm

-

Cleaning:

-

Auto

-

Glue viscosity:

-

<3500

-

Power Supply:

-

AC:220±10%,50/60HZ, 2.5Kw

-

Control Method:

-

PLC+Touch screen

-

Dimension(mm):

-

L1300*W1100*H1500

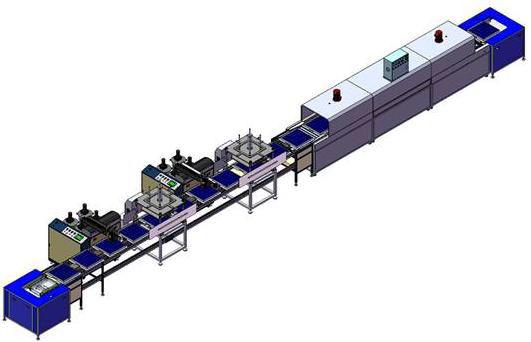

High precision Automatic PCBA Glue dispensing mixing potting machine

Products Description

Potting Solution:

This solution through the automatic glue potting machine, vacuumizing and automatic curing, the whole glue potting process is automated. With the aid of fixture, labor is saved and the purpose of standardization is achieved.

Process:Loader+Potting+Vacuum+Potting+Vacuum+Curing+Unloader.

Application:

Glue Potting Machine I.C.T GP800

1. Touch operation interface, easy to learn and understand.

2. 2500 groups of glue filling parameters can be stored, and the glue filling of the same workpiece does not need to be

reprogrammed.

2. 2500 groups of glue filling parameters can be stored, and the glue filling of the same workpiece does not need to be

reprogrammed.

3. The glue dispensing speed and time can be set by parameters, and the glue output is stable without glue leakage.

4. Save labor, and one equipment can reach the output of traditional 5-6 people.

5. Mix according to the demand to realize glue filling while mixing, so as to save glue to the greatest extent.

6. Double barrel design, a glue and B glue are stored separately to ensure that the glue will not solidify after being placed

for a long time.

7. The mixing ratio is 1:1, dynamic / static mixing is adopted, and the mixing is uniform and sufficient.

8. Unique control system, not affected by air pressure factors, to avoid uneven glue, wire drawing, bubbles and other

phenomena.

9. According to the production needs, multi head glue can be used to effectively improve the production process and efficiency.

10.Optional glue mixing, heating and vacuum defoaming function are reserved, which is suitable for different kinds of pouring processes.

4. Save labor, and one equipment can reach the output of traditional 5-6 people.

5. Mix according to the demand to realize glue filling while mixing, so as to save glue to the greatest extent.

6. Double barrel design, a glue and B glue are stored separately to ensure that the glue will not solidify after being placed

for a long time.

7. The mixing ratio is 1:1, dynamic / static mixing is adopted, and the mixing is uniform and sufficient.

8. Unique control system, not affected by air pressure factors, to avoid uneven glue, wire drawing, bubbles and other

phenomena.

9. According to the production needs, multi head glue can be used to effectively improve the production process and efficiency.

10.Optional glue mixing, heating and vacuum defoaming function are reserved, which is suitable for different kinds of pouring processes.

Specification :

|

Model

|

I.C.T GP800

|

|

Nozzle Number

|

1(Multiple head is option)

|

|

Axis Number

|

3-Axis X,Y,Z

|

|

Table Size

|

<500*500mm

|

|

Z-axis Adjustment

|

0-100mm

|

|

Cleaning

|

Auto

|

|

Gluing material

|

Silicone,epoxy.PU,etc.

|

|

Glue viscosity

|

<20000

|

|

Power Supply

|

AC:220±10%,50/60HZ, 2.5Kw

|

|

Control Method

|

PLC+Touch screen

|

|

Dimension(mm)

|

L1800*W1800*H1500

|

|

Weight

|

Approx:580kg

|

Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of electronic industry experience, through our superior resources in China to provide global customers with systematic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customers to set up factories in LED, TV, mobile phone, DVB, EMS and other industries all over the world.

We are trustworthy.

Our Advantages

Exhibition

Packing & Delivery

※ Standard Wooden Case with Vacuum Package

Shipping Way:

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 35 Days.

※ By air, for sample and small package, international express like DHL, UPS, EMS...

※ By sea, for large package and quantity;

※ Other ways as customer requested.

Delivery Time:

※ Within 35 Days.

FAQ

|

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner |

|

Q: Are you a trade company or manufacturer?

A: Full SMT machines maufacturer for smt line in China; OEM & ODM service are available. |

|

Q: What is your delivery date?

A: About 35 days after receipt of payment. |

|

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment. |

|

Q: What your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc. |

|

Q: Why choose you?

A: Leading SMT Supplier in China; Professional Supplier on Alibaba; Trade assurance to USD 560,000+; Professional after-sales service team. |

Hot Searches