2. Input Volume 1200L

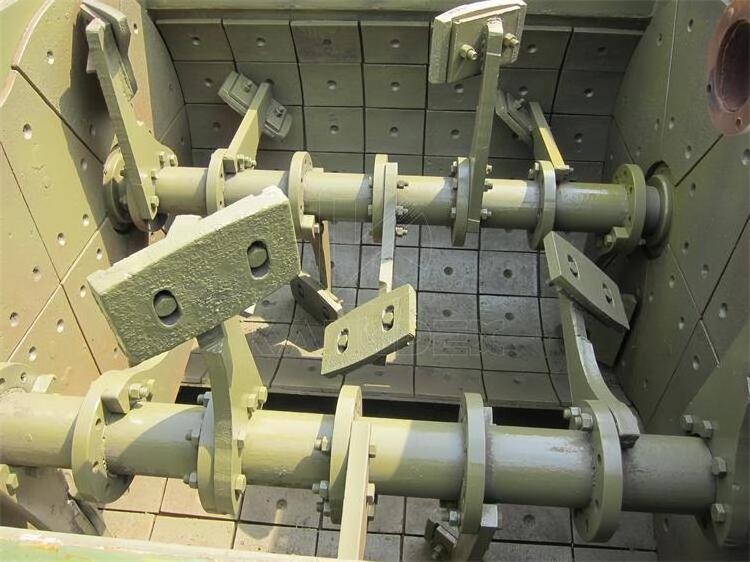

3. Single motor and reducer

4. Mixing Motor 30Kw

5. High strength wear resistant mixing blades and lining plates

6. Electric Lubricating System

7. Pneumatic Discharging

|

Parameters of

ready mix concrete batching plant

|

|

|

||

|

Item

|

Model

|

HZS35

|

||

|

Whole Plant

|

Max Theory Productivity

|

35 m3/h

|

||

|

Whole Plant

|

Cycle Time

|

60s

|

||

|

|

Feeding Way

|

Skip Hoist

|

||

|

|

Maximum Size of Aggregate

|

60/80 mm

|

||

|

|

Discharge Height

|

3.8m

|

||

|

|

Total Power

|

60kw

|

||

|

|

Total weight

|

12Ton

|

||

|

Concrete Mixer

|

Twin Shaft Concrete Mixer

|

JS700 (750L, Pneumatic Discharging)

|

||

|

Aggregate Batcher

|

Batching Machine

|

PLD1200 (2 bins or 3 bins)

|

||

|

Measuring Accuracy

|

Aggregate Measuring Accuracy

|

2250kg ±2

|

||

|

Weighing Accuracy

|

Cement Measuring Accuracy

|

450kg ±2

|

||

|

|

Fly Ash Measuring Accuracy

|

450kg ±2

|

||

|

|

Water Measuring Accuracy

|

300kg ±2

|

||

|

|

Additive Measuring Accuracy

|

30kg ±2

|

||

|

Pneumatic System

|

Air Compressor

|

1.67m3/min, 0.8Mpa

|

||

|

Control System

|

Semi/Fully Automatic Control

|

PLC+Computer

|

||

|

|

Electrical System

|

Power Distribution Cabinet

|

||

|

Remarks: Standard Voltage/Hertz: AC380V/50HZ, it is adjustable according to buyer's country

|

Voltage/Hertz: AC380V/50HZ (adjustable)

|

|

||