- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LYJW

-

Model Number:

-

According to the model, Single Row cross roller bearing slewing ring bearing

-

Place of Origin:

-

Henan, China

-

Material:

-

42CrMo/50Mn/other

-

Application:

-

Manufacturing Plant, Machinery Repair Shops, Construction

-

Cage:

-

Nylon

-

Certificate:

-

CCS ABS BV DNV

-

Service:

-

OEM Customized Services

-

Package:

-

Wooden Box

-

Size:

-

According to the model

-

weight:

-

According to the model

-

MOQ:

-

1

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

-

Feature:

-

CROSS ROLLER

-

Seals Type:

-

According to the model

-

Brand Name:

-

LYJW

-

Model Number:

-

According to the model, Single Row cross roller bearing slewing ring bearing

-

Place of Origin:

-

Henan, China

-

Material:

-

42CrMo/50Mn/other

-

Application:

-

Manufacturing Plant, Machinery Repair Shops, Construction

-

Cage:

-

Nylon

-

Certificate:

-

CCS ABS BV DNV

-

Service:

-

OEM Customized Services

-

Package:

-

Wooden Box

-

Size:

-

According to the model

-

weight:

-

According to the model

-

MOQ:

-

1

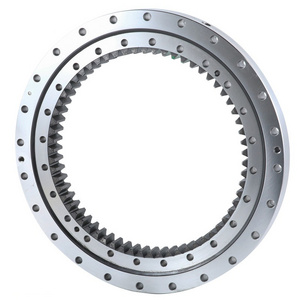

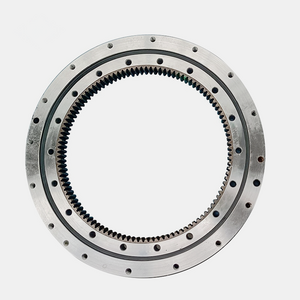

Product Description

LYJW slewing bearings can be divided into single-row four-point contact ball slewing bearings, single-row cross roller slewing bearings, double-row different ball diameter slewing bearings, three-row cylindrical roller slewing bearings and ball combined slewing bearings according to their structure. The product diameter ranges from 100-15000 mm.

This type of bearing can be divided into no-gear bearings, external gear bearings and internal gear bearings.

The bearings we produce have the characteristics of reasonable design, light weight, high carrying capacity, and wide application range.

This type of bearing can be divided into no-gear bearings, external gear bearings and internal gear bearings.

The bearings we produce have the characteristics of reasonable design, light weight, high carrying capacity, and wide application range.

Four-point contact ball slewing bearing

Double-row ball slewing bearing

Three-row cylindrical roller slewing bearing

Cross roller bearing

Flange slewing bearing

Raceways

The raceways of slewing rings are quenched on the surface. Its quenching hardness is HRC55-62, making sure that its effective hardening depth is enough.

Seals

The sealing of the slewing bearing, on the one hand, is to prevent the leakage of filled grease, on the other hand, is to prevent the outside dust, impurities and moisture from invading into the exterior of the bearing and affecting its work. The sealing ring of LYJW slewing bearing is made of nitrile rubber material, which is resistant to high temperature and corrosion.

Production Process

Raw material

LYJW bearing rings are made of high quality 42CrMo/50Mn and the raceway surface is quenched. We can provide rings of other materials according to customer’s specific requirements.

Rough turning

* After rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life.

Heat treatment

* Perform medium frequency hardening on the surface of bearing raceway to form a hardened layer with hardness≥55HRC, depth≥4mm and the width of soft zone is≤50mm with a “S” mark on it.

Gear Processing

For bearings with external or internal gear, gear processing should be performed prior to grinding process to achieve the required

gear accuracy.

gear accuracy.

Drilling

Program on the CNC drilling machine according to the drawing and verify the size accuracy prior to drilling holes.

Grinding

Fine grinding: 46 or 60 grit resin grinding wheel is used to finely process the slewing bearings and achieve the required surface finish and size accuracy.

Assembly

After grinding, pre-assembly is carried out to calculate and adjust the clearance.After adjusting the clearance, check the start friction torque. If it is not acceptable, adjusting the race way and clearance again to achieve the required value.

Inspection- Calipers

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System. Every process from materials to finished products is inspected and documented to control the quality of every piece of bearing.

Dial indicator

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System. Every process from materials to finished products is inspected and documented to control the quality of every piece of bearing.

Altimeter

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System.

Quenching hardened layer depth tester

LYJW performs strict quality control in compliance with ISO9001-2015 Quality Management System.

Packaging & Shipping

The qualified products are cleaned, greased, packaged, crated, and shipped to the customer with related certifications.

Hot Searches