- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GNS

-

Model Number:

-

S99 building silicone sealant

-

Type:

-

Sealant

-

OEM:

-

Avaliable

-

Cetificate:

-

ISO, TUV

-

Carton type:

-

five ply master carton

-

Packing:

-

24 pcs in a carton

-

Colour:

-

white, black and grey

-

Shelf life:

-

12 months

-

Skin Time(Min):

-

5-10

-

Tack-free Time(hour):

-

≤1.0

-

Curing time(5mm):

-

≤12

-

Specific Gravity(g/ml):

-

0.97±0.02

Quick Details

-

CAS No.:

-

4253-34-3

-

Other Names:

-

silicone sealant

-

Place of Origin:

-

China

-

Brand Name:

-

GNS

-

Model Number:

-

S99 building silicone sealant

-

Type:

-

Sealant

-

OEM:

-

Avaliable

-

Cetificate:

-

ISO, TUV

-

Carton type:

-

five ply master carton

-

Packing:

-

24 pcs in a carton

-

Colour:

-

white, black and grey

-

Shelf life:

-

12 months

-

Skin Time(Min):

-

5-10

-

Tack-free Time(hour):

-

≤1.0

-

Curing time(5mm):

-

≤12

-

Specific Gravity(g/ml):

-

0.97±0.02

GNS S99 Building Silicone Sealant

GNS S99 Building Silicone Sealant is a neutral cure, one part, non-mixing required, RTV silicone sealant, Mildew resistance which can be applied in kitchen, bathroom and sanitary wares like shower screens, bath-tubs, sink and so on. General glazing application for different substrates like glass, ceramic tiles, porcelains, aluminum. Place where high humidity is encountered. Can be applied in any season with excellent weathering UV light, vibration, moisture, ozone, temperature extremes.

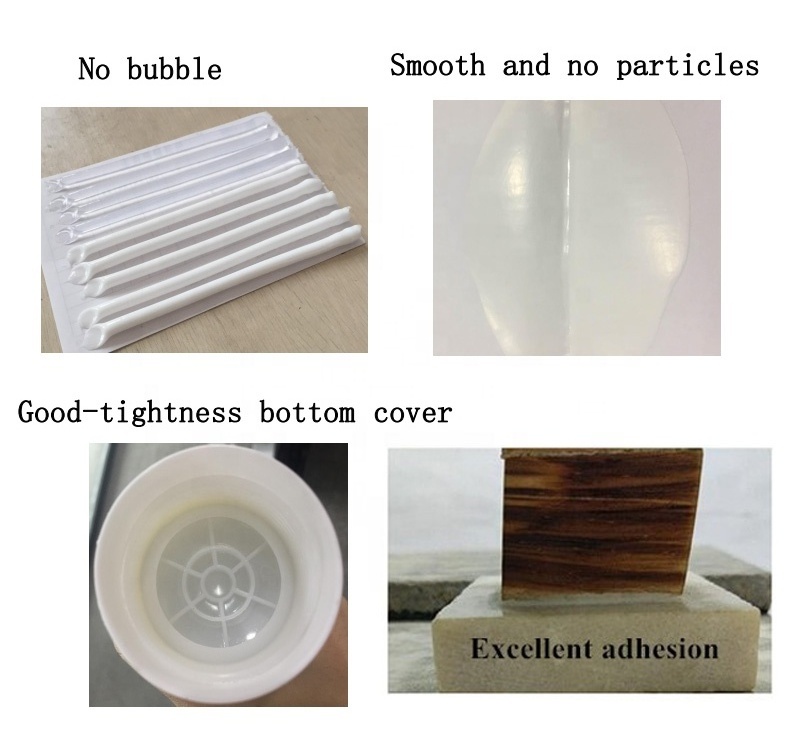

FEATURES

l One part, can be easily used and extruded with common caulking guns.

l Excellent adhesion to most construction materials.

l Outstanding weatherproofing ability, resisting to ultraviolet ray (UV), ozone, snow or temperature extremes.

l Neutral cure, non-acidic, will not corrode metal or other corrosion-sensitive material.

l Resistant to mold and mildew growth.

TYPICAL USE

l Aluminum composite panels cladding, aluminum and glass curtain walls.

l General glazing and weather sealing in curtain walls and building facades.

l Windows & doors perimeter joints. e.g. Vinyl windows, aluminum windows, PVC, UPVC window s etc.

l Glass, aluminum, ceramics, metals, steel, fiberglass, most plastics, tiles, bricks, marble & granite surfaces and so on.

PACKAGING

A vailable in:

Standard Size:

300ml recyclable plastic cartridge, 24ctgs/ctn

590ml aluminum sausage, 20ssgs/ctn

Special Size:

Contact us for special size.

COLORS

A vailable for four standard colors: Translucent, White, Black, Aluminum.

Contact us for special colors.

STORAGE AND SHELF LIFE

12 months from manufacture date when store in cool dry locations below 25℃, keep away from heat source and direct sunlight during storage.

PERFORMANCE DATA

|

Test Parameter |

Unit |

Result Translucent Pigmented |

|

|

As Supplied Tested at 23℃ and 50% RH |

|||

|

Specific Gravity |

g/ml |

1.00±0.02 |

1. 43 ±0.02 |

|

Flow (sag or slump) |

mm |

0 |

0 |

|

Extrusion Rate Skin Time |

ml/minute minute |

100 5~10 |

123 ≤80 |

|

Tack-free Time |

hour |

≤1 |

≤8 |

|

Curing time (5mm) |

hour |

≤12 |

≤15 |

|

As Cured-after 21 days at 23℃ and 50% RH |

|||

|

Durometer Hardness, Shore A |

Points |

28 |

36 |

|

Elastic Recovery |

% |

98 |

98 |

|

Movement Capability |

% |

±25 |

±40 |

|

Tensile/Modulus at 50% Elongation |

Mpa |

0.27 |

0.52 |

|

Tensile/Modulus at 100% Elongation |

Mpa |

0.35 |

0.68 |

|

Ultimate Tensile Strength Ultimate Elongation at Break |

Mpa % |

0.37 175 |

0.84 400 |

APPLICATION

Cut seal on top of cartridge. Screw on nozzle and cut the nozzle at 45°angle to the desired shape and size. For better appearance, cover outside of joint areas with masking tapes before application. Tool immediately after sealant application and remove masking tape before sealant skins

SURFACE PREPARATION

Clean all grease, dirty, water, c lunky sealant from surface, accessories and protective coatings and any pollutant left inside joints and sunken parts. For best results wipe all surfaces with GNS cleaner, methylated spirits or acetone, use a lint free cloth, then wipe again with a dry lint free cloth. Detergent or soap water treatments are not recommended.

COMPATIBILITY TESTING

Incompatibility of glazing materials can lead to sealant discoloration and/ or loss of adhesion. To help protect against these problems and to ensure compatibility, GNS will also test and provide information on the compatibility of accessory materials (gaskets, spacers, etc.) and other GNS s ilicone sealants.