- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZTZG

-

Power:

-

600KW

-

Raw material:

-

Low-carbon Steel

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Pipe application:

-

Construction Tubes

-

After-sell service:

-

Overseas Maintenance

-

Usage:

-

Industrial Areas

-

Pipe diameter:

-

25.4-76.2mm

-

Function:

-

Forming Welding

-

Related machine:

-

Slitting Line

-

Model:

-

Electric Concrete Pole Making Machine

-

Welding:

-

TIG Welder

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Germany, Viet Nam, Brazil, Peru, Indonesia, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan

-

After-sales Service Provided:

-

Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Quick Details

-

Pipe Material:

-

Carbon steel

-

Production Capacity:

-

98%

-

Place of Origin:

-

China

-

Brand Name:

-

ZTZG

-

Power:

-

600KW

-

Raw material:

-

Low-carbon Steel

-

Pipe shape:

-

Round Square Rectangle Pipe

-

Pipe application:

-

Construction Tubes

-

After-sell service:

-

Overseas Maintenance

-

Usage:

-

Industrial Areas

-

Pipe diameter:

-

25.4-76.2mm

-

Function:

-

Forming Welding

-

Related machine:

-

Slitting Line

-

Model:

-

Electric Concrete Pole Making Machine

-

Welding:

-

TIG Welder

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Germany, Viet Nam, Brazil, Peru, Indonesia, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan

-

After-sales Service Provided:

-

Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd. is established in 2000,locates in Shijiazhuang, the capital city of Hebei Province. Adjacent to Beijing City,we are endowed with convenient transportation and geographical condition.

We combine development, production, sales with service, our technicians work stably with precise working style. The production line adopts assembly line method with exquisite technology, well- found inspection equipment for production. In recent years, our company has become a considerably scaled manufacturer of welded pipe production line in China. Our products are sold all over the country. We served equipments with high quality to some domestic large scale enterprises such as Steel Pipe Mill Of Shengli Oil Field, Jiangsu Sujia Group, Kunming Steel Group, Nanjing Wanrun etc.Our products are exported to Southeast Asia as well. We succeeded in developing complete plants with advanced international standards such as H.F. straight welded pipe prodution line for φ20-φ610, multi-functional cold rolled section steel welded pipe production line LW100-LW2200, slitting line ZJ100-ZJ2200 etc. We take the fancy within the industry and new and old customers because of excellent production quality.

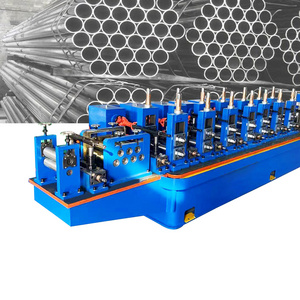

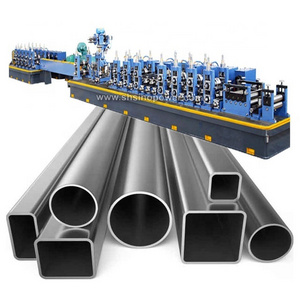

ERW rectangle GI/galvanized steel pipe making machine is specialized equipment to produce high frequency straight seam welded pipes for structural pipe and industrial pipe . These ranges can be adjusted according to customers’ need .Through optimization design, best materials choice, and accurately fabrication and rolls, the whole line can be reached high precision and high speed. Within suitable range of pipe diameter and wall thickness, pipe production speed can be adjusted.

|

Model |

Specification |

Thickness ( mm ) |

Working Speed ( m/min ) |

||

|

HG 20 |

Φ8-Φ20 |

0.3-1.5 |

120 |

||

|

HG 32 |

Φ10-Φ32 |

0.5-2.0 |

120 |

||

|

HG 50 |

Φ20-Φ50 |

0.8-3.0 |

120 |

||

|

HG 76 |

Φ32-Φ76 |

1.2-4.0 |

120 |

||

|

HG 89 |

Φ42-Φ89 |

1.5-4.5 |

110 |

||

|

HG 114 |

Φ48-Φ114 |

1.5-4.5 |

65 |

||

|

HG 140 |

Φ60-Φ140 |

2-5 |

60 |

||

|

HG 165 |

Φ76-Φ165 |

2-6 |

50 |

||

|

HG 219 |

Φ89-Φ219 |

2-8 |

50 |

||

|

HG 273 |

Φ114-Φ273 |

3-10 |

45 |

||

|

HG 325 |

Φ140-Φ325 |

4-12.7 |

40 |

||

|

HG 377(355) |

Φ165-Φ377(355) |

4-14 |

35 |

||

|

HG 406 |

Φ219-Φ406 |

6-16 |

30 |

||

|

HG 508 |

Φ273-Φ508 |

6-18 |

25 |

||

|

HG 660 |

Φ325-Φ660 |

6-20 |

20 |

||

|

HG 720 |

Φ355-Φ720 |

6-22 |

20 |

||

Main Products

1) H.F.Straight Welded Pipe Production Line:

2) Diameter: Φ8mm-Φ720mm Wall Thickness : 0.3mm-22mm

3) Square/Rectangular: 10X10mm-600X600mm Wall Thickness : 0.3mm-22mm

4) Abroach Cold Rolled Section Steel Production Line: LW80X2mm-LW2200X19mm

5) Multi-functional Cold Rolled Section Steel/Welded Pipe Production Line: LW100X100mm-LW500X500mm

6) Other Auxiliary Equipments and Rolls etc.

7) Slitting Line: ZJ100mmX2mm-ZJ2200mmX20mm

8) Stainless Steel Pipe Production Line: Φ20mm-Φ508mm

Square to Square Welded Pipe Production Line

This way is to directly roll the steel strip and bend it to square & rectangular shape, then weld to finish the formation.

Characteristics & Advantages:

1)Compared with roun to square forming method,this method can make:bettershape of angles for crosssection,smaller semidiamter of inner arcis,flatter brim,regular outlook;

2)Low load for the whole line,especially in the sizing part;

3)2.4-3% strip width sbrinkage than round square forming method,so that to save raw materials;

4)By advance multi-point bending,avoiding the axial force and side abrasion,reducing the forming step and ensuring theq- uality,meanwhile reducing power wastage and roll abrasion; 5)By combined rolls,one set can be used to produce lots of sq- uare & rectangular pipes for different

specifications.This can decrease the storage of rolls,lower 80% roll cost,fast the bankroll turnover, shorten developing time for new lines.

This steel tube making machine can produce different kind of steel pipes:

1. Water pipe

2. Heating pipe

3. Low-pressure process pipeline

4. Low pressure fire fighting pipeline

5. Sewage Pipes

6. Steel Scaffolding Pipe

7. Wire and cable protection pipe

8. Structural support Steel Pipe

9. Industrial Steel Pipes

10. Decoration Pipe

11. Oil & Gas Pipes