- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GY

-

Dimension(L*W*H):

-

57*23*45CM

-

Weight:

-

28KG

-

Warranty:

-

12 Months

-

Working Temperature Range:

-

1 - 40 ℃

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Heating, Forging, Melting, Hardening and etc

-

Duty Cycle:

-

100%

-

Work Power:

-

380V,3PHASE

-

Customized:

-

Customized

-

Work Condition:

-

Continuously for 24 hours

-

Operation:

-

Safe&Easy

-

Frequency:

-

High Frequency

-

Cooling:

-

Water

-

Certification:

-

CE ROHS FCC

Quick Details

-

Type:

-

Band Heater

-

Power Source:

-

Electric

-

Voltage:

-

220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GY

-

Dimension(L*W*H):

-

57*23*45CM

-

Weight:

-

28KG

-

Warranty:

-

12 Months

-

Working Temperature Range:

-

1 - 40 ℃

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Heating, Forging, Melting, Hardening and etc

-

Duty Cycle:

-

100%

-

Work Power:

-

380V,3PHASE

-

Customized:

-

Customized

-

Work Condition:

-

Continuously for 24 hours

-

Operation:

-

Safe&Easy

-

Frequency:

-

High Frequency

-

Cooling:

-

Water

-

Certification:

-

CE ROHS FCC

Brand New High Frequency Induction Coil Heater 15KW

Induction Heater Main Feature

Our induction heat treatment process is best suited for enhancing the ductility of steel, stainless steel, and carbon steel parts without compromising on the dimensional stability of the materials. In addition, our induction heating process is environmentally friendly and offers higher heating intensity compared to conventional metal treatment techniques.

Induction heating – a highly efficient technology for heating metals in very short times

GuangYuan Induction Heater offer excellent technical properties for the induction heating of metals. Induction heating is a very quick and precise process as heat is applied selectively only to parts of the workpiece where heat treatment is desired. Induction is generally suitable for all electrically conductive materials.

Induction Heater Application

Forging(Bar,flat plate,bar end heating,pipe ends,bar end heating)

Pre-heating(Pipe,steel wire,stainless steel wire)

Brazing(Saw blades,carbide tools,cooper tube,aluminum part,drilling tools,Pan)

Annealing(Steel pipe,golf ball head,brass lock,aluminum pan)

Hardening(Gear,shaft,pipe,bearing,pump fitting,steel plate,roller)

shrink fitting(motor,pipe)

Melting(Iron,steel,brass,aluminum,silver,zinc)

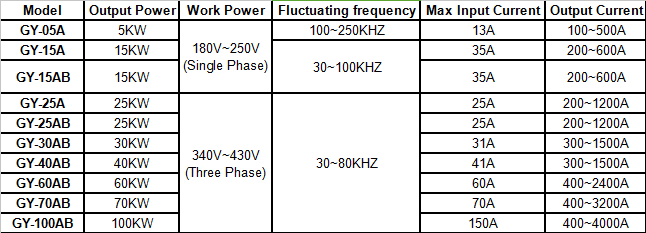

High Frequency Induction Heater Parameter:

Forging

Induction Forging --- a highly efficient technology for heating metals in very short times.

Apply for Fastners,Screw,Steel rod,steel bar,flat plate,bar end heating,pipe ends,bar end heating,Pipe,steel wire,stainless steel wire,Auto Parts and etc.

Main Features

Induction Brazing ----- the joining procedure for high-quality joints of metallic parts.

Apply for Various hardware cutting tools,diamond tools,abrasive tools,drilling tools,saw blade,milling cutter,kettle products,copper fittings,stailess steel pot, refrigerating copper fitting,short circuit rings,heat exchangers, automotivve swivel fitting,pole coils,Pins and etc.

Quenching

Induction hardening is the process by which metal is heated then rapidly cooled in order to increase the hardness of the material.

Apply for Shaft,gear,chain wheel,gear wheel,shear,screwing,motocycle fittings,crankshaft,axes,hardware metal parts,plier,wrench,hammer, roller,punch and etc.

Main Features

Induction melting is a safe and reliable process for the melting of metals

Apply for Iron,steel,brass,aluminum,silver,zinc,copper,

Gold,lead,Stainless Steel,Platinum melting.

Hardening

Induction hardening is the process by which metal is heated then rapidly cooled in order to increase the hardness of the material.

Apply for Shaft,gear,chain wheel,gear wheel,shear,screwing,motocycle fittings,crankshaft,axes,hardware metal parts,plier,wrench,hammer, roller,punch and etc.

Induction Heating Machine

91.8% Response Rate

Induction Heater

98% Response Rate

Induction Heating Equipment

91.8% Response Rate