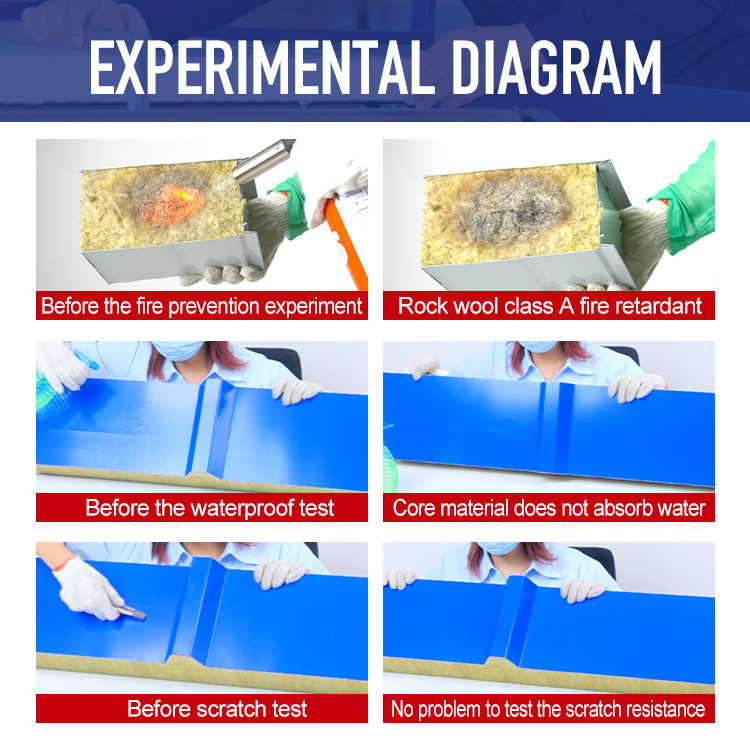

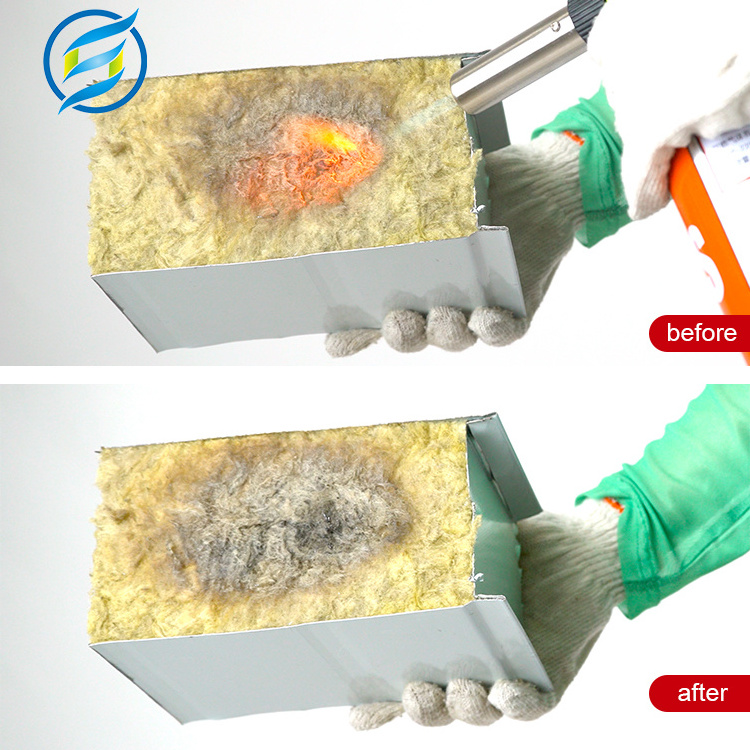

effectively block the spread of the flame in a fire and minimize the fire.

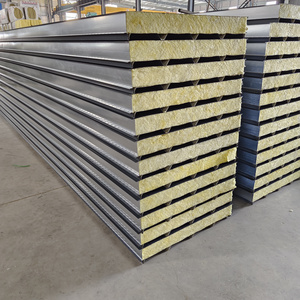

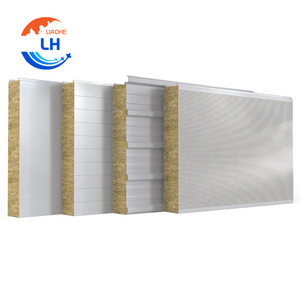

Insulation and energy saving:

rock wool has low thermal conductivity (λ = 0.043w/m·k), and good thermal insulation performance.Excellent node design ensures sealing performance and thermal insulation effect.