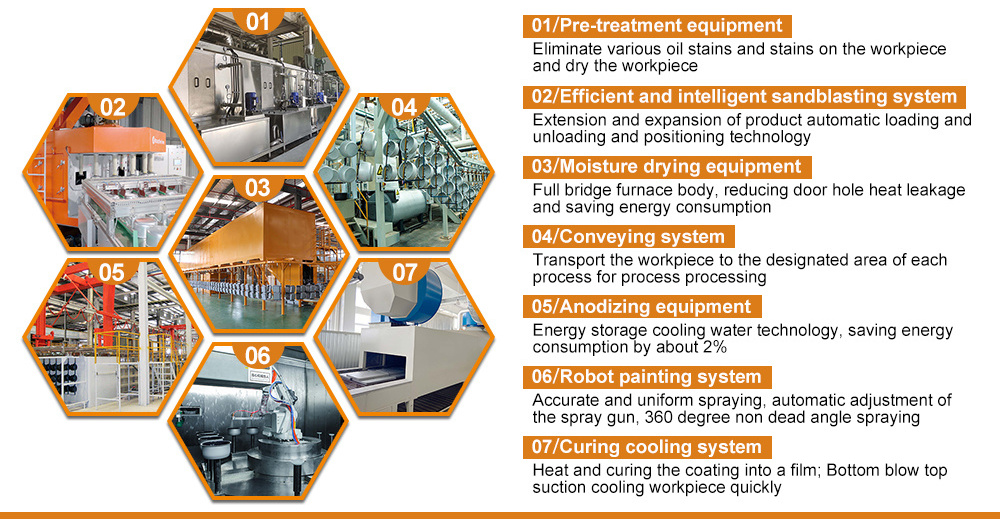

1. The spraying room adopts a multi-level sprinkler system, which reduces the amount of paint mist in the exhaust gas of the spraying room by 30% and reduces the load of air duct cleaning and exhaust gas treatment.

2. Track painting with high speed, reduce the paint consumption by fixed gun and paint has save more than 10%.

3. It heats by the rest heat of curing oven through the exchanger of drying heating room that it saves energy.

4. It designs 3 sections in curing oven to avoid the heat loss in the oven when conveying. Transitional device ensures transportation and operation stability.

5. Quick changing between non-stick paint and ceramic paint in the inner coating line, it saves the processing time.

6. The chains of the full coating line fix very well so that it reduces the quantity of fixture.

7. The conveyor chain is higher type which is 60mm more than the old type chain, it has the advantage of conveying stability so that the workpiece on the line runs stability.

8. The automatic rotating device of the outer coating line is configured with belt transferring device which ensure the painted workpieces are good quality and stability when the workpieces are running.

9. The waste gas of curing oven is configured with variable frequency type exhaust fan. In the same time, it can meet all of the paints and ceramic paint process requirement and make sure the paint quality on the workpiece.