- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

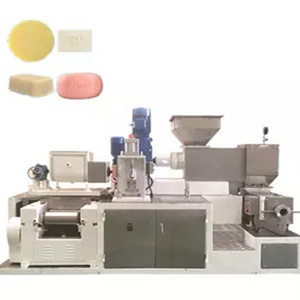

Soap Making Machine, Soap Production Line

-

Product name:

-

soap making machine

-

capacity:

-

100-2000kg/h

-

Machine Materials:

-

stainless steel

-

Process type:

-

toilet /laundry soap line

-

Type:

-

automatic

-

Feature:

-

High Effeciency

-

After Warranty Service:

-

Video technical support, Online support

-

PACKING:

-

Wooden Case

-

Motor Power (kW):

-

30kw

-

Application:

-

Chemical Industries

Quick Details

-

Place of Origin:

-

Gansu, China

-

Brand Name:

-

LIMAC

-

Weight (KG):

-

2000

-

Machine Type:

-

Soap Making Machine, Soap Production Line

-

Product name:

-

soap making machine

-

capacity:

-

100-2000kg/h

-

Machine Materials:

-

stainless steel

-

Process type:

-

toilet /laundry soap line

-

Type:

-

automatic

-

Feature:

-

High Effeciency

-

After Warranty Service:

-

Video technical support, Online support

-

PACKING:

-

Wooden Case

-

Motor Power (kW):

-

30kw

-

Application:

-

Chemical Industries

soap machine laundry soap making machine soap bar making machine

Product Description

Making toilet soap and launry soap

Raw material: soap noodles

Capacity: 500-2000KG/H

1. The lines are capable of producing high-performancetoilet or translucent soap.

2. The worm barrel is made from one piece of tube, instead of two tube sections connected together by bolted flanges, which is the usual practice of other soap machine producers in China. The two Sectioned barrel is not as precise as the integral one ,and will cause "biting" of barrel wall, that enters into soap produced, detereorating the quality of product soap.

3. Special worm design with seamless drawn conical core that greatly reduces soap bar forming time, and increases pressure inside the worm barrel, making the soap more compact ,more smooth and transparent.

4. People-oriented design: Proctor & Gamble's management, mantel nuiance,and safety standards are adopted,

5.The machines are better covered, and have more safety measures.The machines are more transparent. so the maintenance workers can see machine parts running inside the machine at any time.

6.The machine is tidy both outside and inside.

7. The finishing line can be running automatically as a whole, Easy to be operated via control panels.

Raw material: soap noodles

Capacity: 500-2000KG/H

1. The lines are capable of producing high-performancetoilet or translucent soap.

2. The worm barrel is made from one piece of tube, instead of two tube sections connected together by bolted flanges, which is the usual practice of other soap machine producers in China. The two Sectioned barrel is not as precise as the integral one ,and will cause "biting" of barrel wall, that enters into soap produced, detereorating the quality of product soap.

3. Special worm design with seamless drawn conical core that greatly reduces soap bar forming time, and increases pressure inside the worm barrel, making the soap more compact ,more smooth and transparent.

4. People-oriented design: Proctor & Gamble's management, mantel nuiance,and safety standards are adopted,

5.The machines are better covered, and have more safety measures.The machines are more transparent. so the maintenance workers can see machine parts running inside the machine at any time.

6.The machine is tidy both outside and inside.

7. The finishing line can be running automatically as a whole, Easy to be operated via control panels.

Specification

|

Type

|

Name

|

Capacity

(kg/h) |

Worm diameter(mm)

|

Motor Power

(kW) |

|

4000ES-DR

|

Duplex single-worm refiner

|

4000

|

400

|

45+45

|

|

3000ES-DR

|

Duplex single-worm refiner

|

3000

|

350

|

37+37

|

|

2000ES-DR

|

Duplex single-worm refiner

|

2000

|

300

|

30+30

|

|

1000ES-DR

|

Duplex single-worm refiner

|

1000

|

250

|

22+22

|

|

500ES-DR

|

Duplex single-worm refiner

|

500

|

200

|

11+11

|

Details Images

Recommend Products

Hot Searches