- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

208/220/380/400/415/440/480V

-

Dimension(L*W*H):

-

Accord to final configuration

-

Weight:

-

10000 kg

-

Capacity:

-

150-2500kg/h

-

Core production technique:

-

Co-rotation twin-screw extrusion

-

Extruder type:

-

Twin-screw extruder

-

Service:

-

Turnkey

-

Heating type:

-

Electric, gas-fired, oil-fired, steam

-

Main production factors:

-

Temperature, pressure, speed

-

Main machine materials:

-

Stainless steel, 38CrMoAl, 45# steel

-

Main food materials:

-

Corn, wheat, rice, brans

-

Feed type:

-

Both floating and sinking

-

Automation degree:

-

Full-automatic

Quick Details

-

Max. Capacity:

-

10

-

Place of Origin:

-

China

-

Brand Name:

-

Shengrun

-

Voltage:

-

208/220/380/400/415/440/480V

-

Dimension(L*W*H):

-

Accord to final configuration

-

Weight:

-

10000 kg

-

Capacity:

-

150-2500kg/h

-

Core production technique:

-

Co-rotation twin-screw extrusion

-

Extruder type:

-

Twin-screw extruder

-

Service:

-

Turnkey

-

Heating type:

-

Electric, gas-fired, oil-fired, steam

-

Main production factors:

-

Temperature, pressure, speed

-

Main machine materials:

-

Stainless steel, 38CrMoAl, 45# steel

-

Main food materials:

-

Corn, wheat, rice, brans

-

Feed type:

-

Both floating and sinking

-

Automation degree:

-

Full-automatic

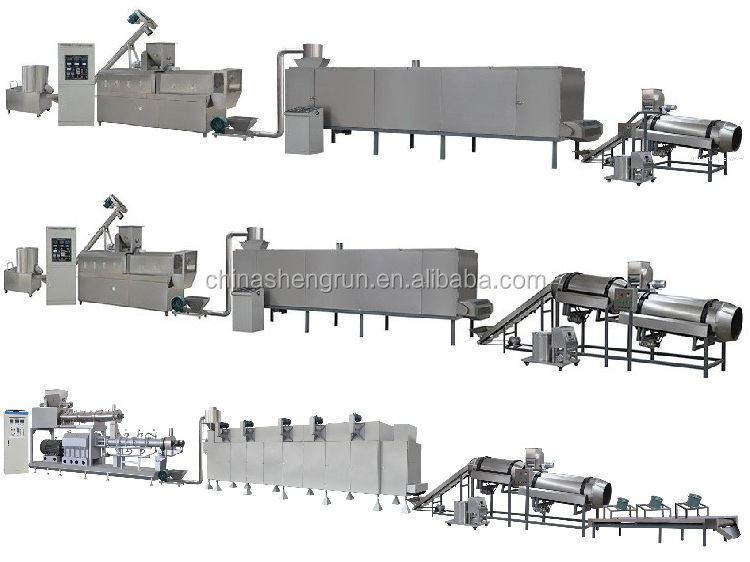

Grain-based materials floating fish feed pellet and fishing bait production line blender extruder dryer crusher and bagger

1. Processing line introduction

This processing line is mainly made up with raw materials treatment system, extrusion system, drying system, flavoring system and controlling system. It has high stability and automatic performance, which offers the possibility to control the expansion of the extrudate through various means to control the texture of the final product.

2. Processing line description

2.1 Flow chart: raw materials→ extrusion→ drying→ flavoring→ cooling→ packing

2.2 Processing line features

2.2.1 High work efficiency, automation degree, materials usage, application range.

2.2.2 Low land occupation, power consumption, labor cost, waste rate.

2.2.3 Various configurations and capacity choices.

2.2.4 This processing line can make both floating and sinking fish feed. It can make pet food as well.

2.2.5 Production factors can be quantified and controlled.

2.2.6 World-class food grade fittings.

2.2.7 All machines and fittings can be custom-made. ODM/OEM is available.

2.2.8 Professional pre-sale, sale and after-sale service.

2.3 Processing line parameters

|

Type |

Model |

Capacity (kg/h) |

Installed Power (kw) |

Actual Power (kw) |

|

Dry

|

TSE65-P |

100-150 |

74 |

52 |

|

TSE70-P |

200-250 |

105 |

75 |

|

|

TSE85-P |

300-500 |

205 |

150 |

|

|

Wet

|

TSE90-P |

800-1000 |

132 |

80 |

|

TSE95-P |

1000-1500 |

165 |

106 |

|

|

TSE120-P |

2000-2500 |

226 |

140 |

2.4 Processing line machines and fittings pictures introduction

2.4.1 Series extruders

2.4.2 Series dryers

2.4.3 Fittings

3. Puffed fish feed introduction

In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded, extruded or puffed fish feed. Adopting cereals, vegetable proteins, vitamins, minerals, fish meal and fish oil as raw materials, and adopting dry-type or wet-type extrusion as manufacturing technique, expanded fish feed is made for both carnivorous and graminivorous fishes. Compared with traditional fish feed, expanded fish feed has the advantages: (1) easier feeding management (2) lower wastage rate (3) lower water contamination (4) higher feed nutritional ingredient use ratio (5) longer storage time. Expanded fish feed improves digestibility and refined the balance of nutrients to match the needs of the different species of fish more precisely at different periods of development. At the same time, expanded fish feed improves the sustainability of the ingredients used. Based on the advantages, expanded fish feed will replace traditional fish feed in the future.

4. Packing and delivery

4.1 Packed by plastic protective film or wooden case, which is seaworthy.

4.2 We can supply fumigation package and certificate.

5. Service

5.1 1 year warranty period.

5.2 Supply free fittings and general tool.

5.3 Engineers available to service machinery overseas.

5.4 Supply formula of raw materials.

5.5 Workshop design suggestion.