- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

22.5*9.00

-

P.C.D:

-

275/285/285.75/335

-

Bolt Hole Type:

-

1*45/SR22

-

Bolt Hole Diameter:

-

24/26/32

-

Product name:

-

Tubeless Wheels

-

Surface Treatment:

-

E-coating

-

Welding feature:

-

Flash Butt Welding/Submerged Arc Welding

-

Bolt holes:

-

8/10

-

C.B.D:

-

214/220/221/222/281

-

Offset:

-

175/170

Quick Details

-

OE NO.:

-

ZHU7457

-

Place of Origin:

-

China, Shandong China

-

Brand Name:

-

KAIPENG

-

Model Number:

-

22.5*9.00

-

P.C.D:

-

275/285/285.75/335

-

Bolt Hole Type:

-

1*45/SR22

-

Bolt Hole Diameter:

-

24/26/32

-

Product name:

-

Tubeless Wheels

-

Surface Treatment:

-

E-coating

-

Welding feature:

-

Flash Butt Welding/Submerged Arc Welding

-

Bolt holes:

-

8/10

-

C.B.D:

-

214/220/221/222/281

-

Offset:

-

175/170

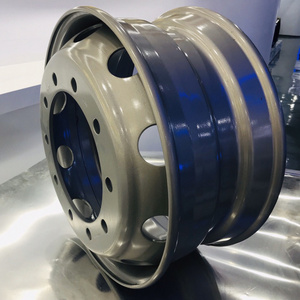

| Product Features | |

| P.C.D | 275/285/285.75/335 |

| OE NO. | ZHU7457 |

| Material | Steel |

| Bolt Hole Type | 1*45/SR22 |

| Bolt Hole Diameter | 24/26/32 |

| C.B.D | 214/220/221/222/281 |

| Model Number | 22.5*9.00 |

| Offset | 175/170 |

| Brand Name | KAIPENG |

| Product name | Tubeless Wheels |

| Surface Treatment | E-coating |

| Welding feature | Flash Butt Welding/Submerged Arc Welding |

| Bolt holes | 8/10 |

| Disc Thickness | 12/14/16/18 |

|

Material

|

Steel

|

|

Surface Treatment

|

E-coating

|

|

Model Number

|

9.00*22.5

|

|

Bolt holes

|

8/10

|

|

Bolt Hole Diameter

|

24/26/32

|

|

Bolt Hole Type

|

1*45/SR22

|

|

P.C.D

|

275/285/285.75/335

|

|

C.B.D

|

214/220/221/222/281

|

|

Offset

|

175/170

|

|

Disc Thickness

|

12/14/16/18

|

|

Rim Thickness

|

6/7/8

|

|

Welding feature

|

Flash Butt Welding/Submerged Arc Welding

|

|

Packaging Details

|

Pallet/Carton/Non Woven Fabrics/Bulk

|

|

Color

|

Silver/Blue/Golden/Black or as your request

|

|

MOQ

|

100 pieces

|

|

Delivery Time

|

Around 15-20 Days

|

|

Type

|

Tube Steel Wheel Rim

|

|

WHEEL SIZE

|

BOLT HOLES

|

PCD(MM)

|

||||

|

HOLES NO

|

HOLE DIA

|

HOLE TYPE

|

||||

|

22.5X9.00

|

10

|

26

|

1*45

|

335

|

||

|

22.5X9.00

|

10

|

26

|

1*45

|

285.75

|

||

|

22.5X9.00

|

10

|

32

|

SR22

|

285.75

|

||

|

22.5X9.00

|

8

|

32

|

SR22

|

285

|

||

|

22.5X9.00

|

10

|

26/24

|

1*45

|

275

|

||

|

CBD(MM)

|

OFFSET

|

THICKNESS

|

EQUIPPED TIRE

|

||

|

DISC

|

RIM

|

||||

|

281

|

175

|

12/14/16/18

|

6/7/8

|

|

|

|

220

|

175

|

12/14/16/18

|

6/7/8

|

||

|

222

|

175

|

12/14/16/18

|

6/7/8

|

||

|

221

|

175

|

12/14/16/18

|

6/7/8

|

||

|

221/214

|

175

|

12/14/16/18

|

6/7/8

|

||

Founded in 2010,Shandong KaiPeng Auto Parts Co.,Ltd is located in National Economic and Technological Development Zone LinYi City.Shandong Provence China. It is a manufacturer integrating R&D, manufacturing and sales of automotive steel rings, with a complete and scientific quality management system. The automobile steel rings, vacuum steel rings and other products produced by the company can prevent the outer edge of the steel ring from being deformed due to excessive force, which will affect the normal use, and effectively prevent the deformation belt. The tires come in deformed wear and out of tires. most of wheel products are exported to Southeast Asia, Africa , Middle East, North America and Russia,South America, KaiPeng expects to cooperate with you.

1)Don't do the best, just do better 2)Quality:Using high-quality raw materials and innovative technology can make your product quality better and more Stable.And enhance market competitiveness 3) Quick Q&A that might save some of your concerns. Sincerity: We are committed to providing high quality products and services.There is no fake and no cheat Experience: We always focus on Technology and Quality,So we got rich professional experiences and had an excellent technical team. Services: We can offer fast pruducting and fast delivery and customized products,With a good after-sales services Win-Win: With a large number of satisfied customers in China.We are looking forward to meet you from all over the world Mission: To deliver high quality and reasonable products to customers all around the world.

Q1. Are you a factory or trading company?

A: We're a self -own factory, with export license.

Q2. Location? How can I visit there?

A: *Our factory locates in LinYi, Shandong, China. *The nearest airport is Linyi QiYangairport.about 17 kilometers

Q3. Lead time for new molds &mass production?

A: *7-10 days to build the new moulds. *Mass production takes 10-15days for a 20gp,15-20days for a 40hq.

Q4. What certification do you have?

A: We are certificated by ISO 9001:2008, factory is reliable and quality is guaranteed.

Q5. Payment terms?

A: Telegraphic Transfer (T/T) and Letter of Credit (L/C).

Q6. Can you send me samples?

A: Yes, with freight is on your side.

Hot Searches