1. with domestic and overseas famous diesel or petrol engines.

2. Import high-precision hydraulic valves, compact and saving energy.

3. Import automatically walks precision sensor, the error is less than 1mm.

4. With an electronic lever sensor, automatically balance from left and right, water lever back-up observing.

5. Import a high protective rank control button.

6. We can customize the kinds of specification molds.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Concrete Curb Machine

-

Application:

-

Concrete

-

Mold:

-

Customized

-

Working type:

-

Walk behind

-

Working speed:

-

1-2m/min

-

Engine:

-

GX160

-

Power:

-

5.5HP

Quick Details

-

Weight (KG):

-

160

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Ideal

-

Product name:

-

Concrete Curb Machine

-

Application:

-

Concrete

-

Mold:

-

Customized

-

Working type:

-

Walk behind

-

Working speed:

-

1-2m/min

-

Engine:

-

GX160

-

Power:

-

5.5HP

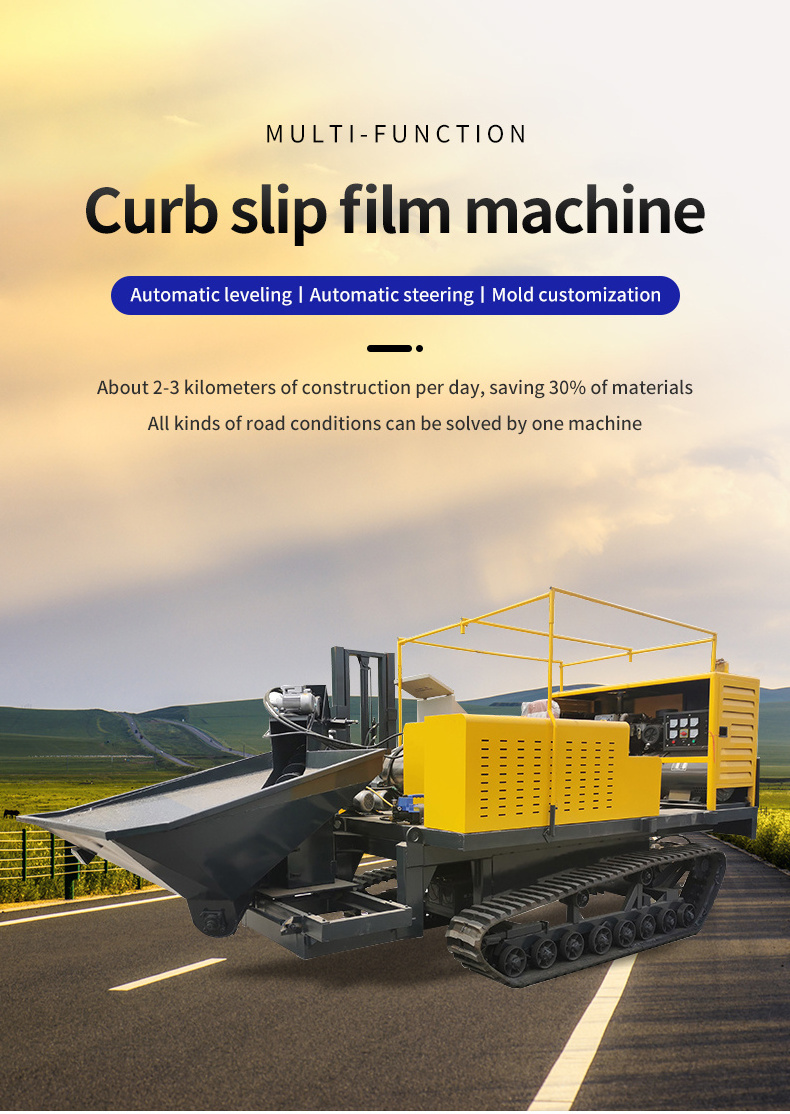

Pavement Curb and Gutter Machine Small Curb Chain Making Machine

The

large capacity walk behind curb machine for producing curbs and blocks concrete curb and gutter machine

is divided into two kinds of power: diesel and gasoline. Both of them adopt hammer extrusion curb (curb stone) sliding mold molding machines. A hammer device is installed in front of the molding mold, and the hammer makes a piston-reciprocating motion to push the cement concrete into the molding mold in a certain period and extrude the curb (curb stone). Similar to the extruded curb (curb stone) sliding form molding machine, the machine relies on the hammer to cement concrete reaction force forward.

Products Description

|

Model

|

ID-ST11

|

|

Working type

|

Walk behind

|

|

Mold

|

Customized

|

|

Working speed

|

1-2m/min

|

|

Engine

|

GX160

|

|

Power

|

5.5HP

|

|

Oil Capacity

|

3.6L

|

|

Paver size

|

20*18cm

|

|

Dimension

|

1670*700*1100mm

|

|

Package size

|

1560*810*970mm

|

|

Weight

|

160KG

|

Adopt spiral blade extrusion type curb (roadside stone barrage) sliding mold molding machine, in front of the molding mold, is installed with spiral blades, blades constantly rotating, cement concrete (asphalt sand) constantly pushed into the molding mold, extrusion molding curb (roadside stone barrage). The action of cement concrete (tar sands) against the spiral blades makes the machine move forward. Curb stones should not be laid on asphalt pavement, but only on water stable layer (except asphalt sand catchment zone).

Product Overview

This small machine can produce small size curb sizes (height≤200mm, width≤180mm), please choose the molds you want in the list, just inform me mold number, and I will check the mold cost for you.

1. The machine, compact and easy to operate, is used for curb forming, especially for the curb forming of recreational green spaces, community garden curbs, etc.

2. With the famous brand engine, reliable performance, easy-to start-up;

3. With a spiral feeding hopper, the counterforce drives the machine backward walking.

4. With a walking indicator ensure the correct direction.

5. Slipform is easy to dismantle and can be designed as per the customer's requirement

2. With the famous brand engine, reliable performance, easy-to start-up;

3. With a spiral feeding hopper, the counterforce drives the machine backward walking.

4. With a walking indicator ensure the correct direction.

5. Slipform is easy to dismantle and can be designed as per the customer's requirement

Product packaging

1 unit was packed into an iron frame and then packed with 5 layers of corrugated carton. 4 strips reinforced the carton. the fix package guaranteed the machines were not damaged during transportation

Hot Searches